INCREASED POWER & EFFICIENCY

Electric Turbo Innovation

Garrett’s Electrified Turbos (E-Turbos) show exciting potential and equal applicability in both light & commercial vehicles, in all fuels such as gasoline, diesel and natural gas (CNG).

Light Vehicle Gasoline

E-Turbo | A Key Technology for EU7

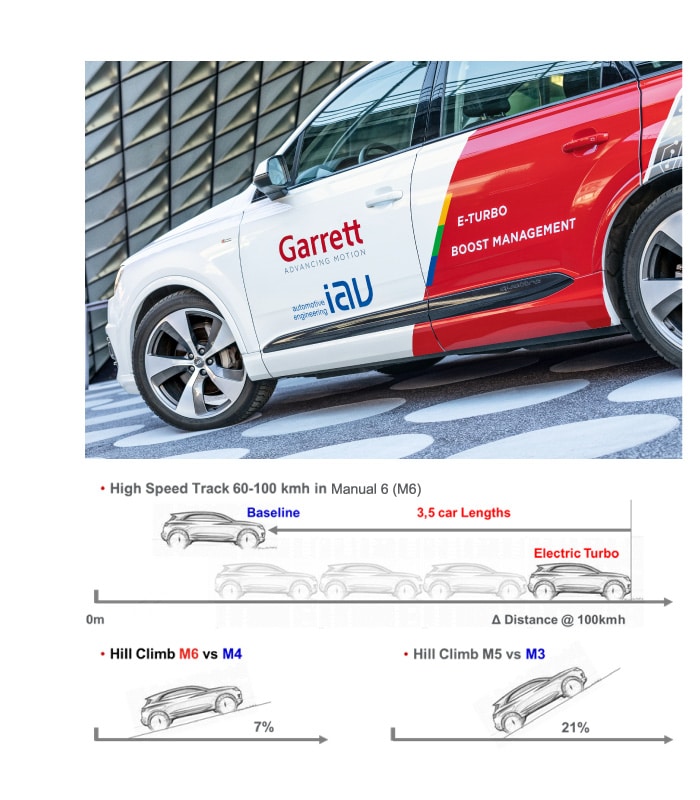

Garrett has created multiple E-Turbo demonstration vehicles that are successful representations of how an electrified boosting solution can increase engine power and torque while allowing the engine to operate at Lambda 1, providing energy recuperation to the vehicle’s electrical system.

Electrifying a turbocharger removes the constraint of needing a small turbine with excellent efficiency to drive the compressor at low flow rates. Instead, it allows us to right-size the turbine for Lambda 1 rated power.

Lambda 1 (or stoichiometric air/fuel ratio) is a key part of future Legislation.

If you are interested to learn more about Garrett electric boosting technology, download the E-Turbo whitepaper.

Strong industry macros indicate that all forms of hybridization set to grow fast (MHEV, HEV, PHEV)

The technologies will be used to meet regional, national, and local fuel economy and air quality targets

e.g. Europe CO2 -15% by 2025, -37,5% by 2030 (vs 2020) RDE – City, Extra Urban & Highway City Access – Tolls & Parking Charges Gasoline – Particulates & Lambda 1 Diesel – NOx & NH3

Powertrains must be hybridized to meet the fuel economy and emission targets of EU7

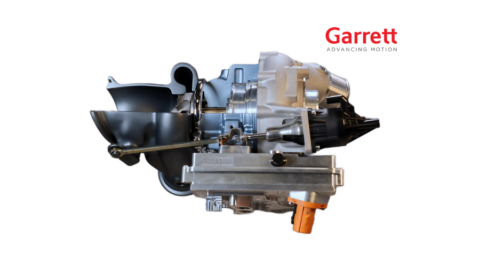

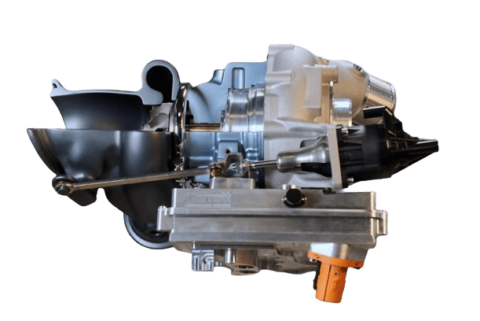

E-Turbo provides an integrated, compact and balanced solution that delivers the additional functionality of Energy Recuperation (Efficient energy Management / Positive effect on state of charge SOC). Any penalty in inertia can, therefore, be more than compensated for by an electric motor and the addition of a wide-range Compressor to improve low-end response and extend high-end performance simultaneously.

If you are interested to learn more about Garrett electric boosting technology, download the E-Turbo whitepaper.

If you are interested to learn more about Garrett electric boosting technology, watch this webinar to understand how E-Turbo enables more efficiency and better performance.

Performance and CO2 potential at EU7 Boundary Conditions

Key Features

EU7 Mainstream Concept

E-Turbo Key Benefits

Ready Today to Meet & Exceed the Industry’s Electric Boosting Needs

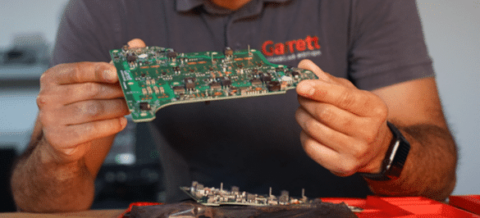

Garrett’s award-winning E-Turbo is ready today to meet and exceed the industry’s electrification boosting needs. The result of unparalleled engineering expertise and advanced electric capabilities, Garrett’s E-Turbo was developed entirely in-house, from concept to reality.

Read these papers and review all features of 48V and 400V Electric Turbo and 48V electric compressor.