Engine performance and efficiency while reducing overall size

Improved Fuel Economy & Driveability in a downsized design

Diesel Benefits

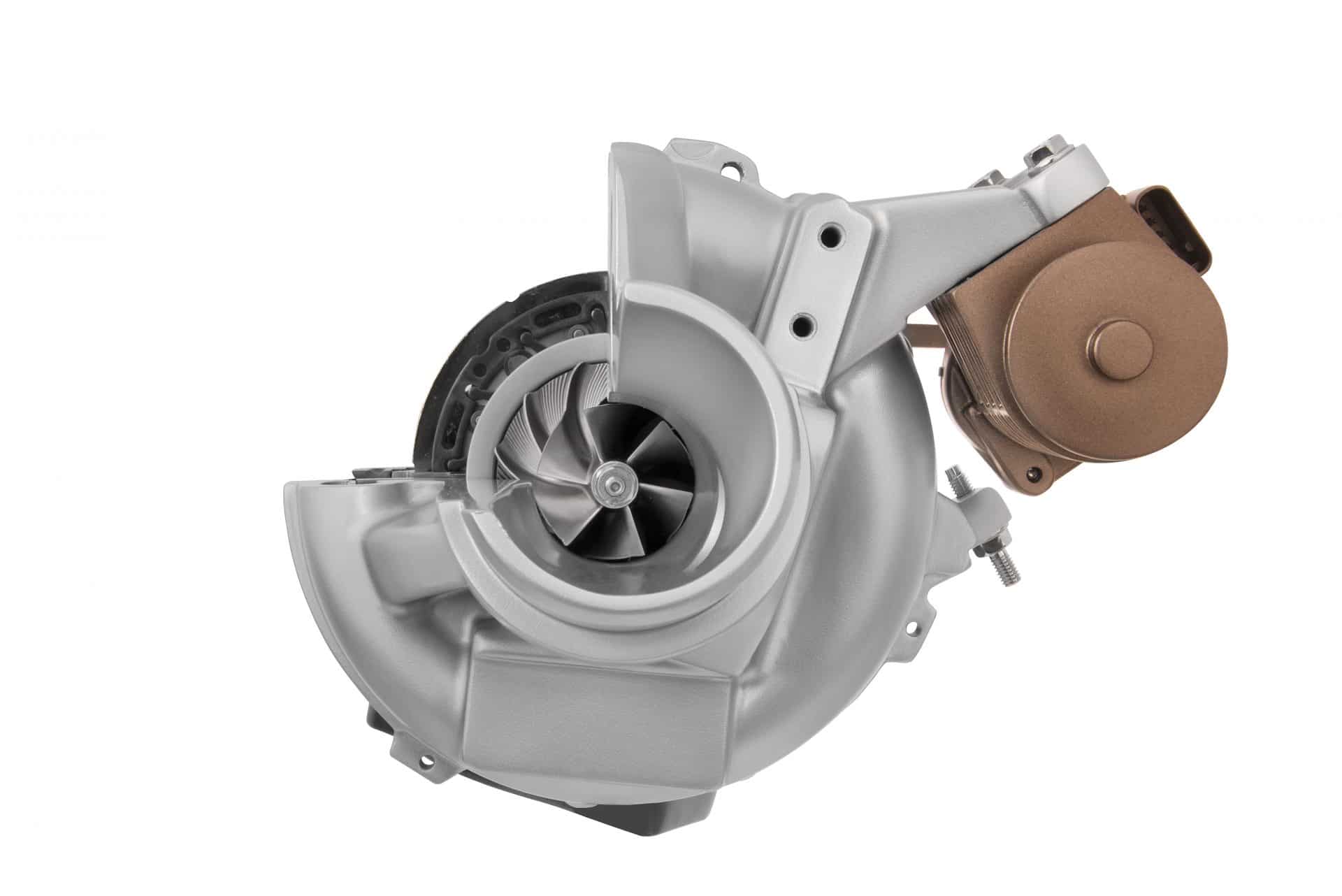

Compared to fixed geometry turbos, our variable geometry turbos (VGT) for diesel engines increase engine power and torque while reducing backpressure. This improves performance, engine control, drivability, and fuel efficiency without compromising power. Other benefits include:

Variable Geometry Turbos for Diesel Key Features

A variable geometry turbo for a diesel engine controls engine exhaust flow through the turbine wheel using a row of vanes. These vanes open and close to match the engine’s exact boost requirements.

At LOW SPEEDS, the vanes close, which:

- Restricts exhaust airflow through the turbine

- Increases turbine power

- Increases boost pressure

At HIGH SPEEDS, the vanes open, which:

- Maximizes exhaust gas flow

- Avoids turbo over-speed

- Maintains required boost pressure

Our PATENTED PRESSURE BALANCE directs exhaust gas to both sides of the vanes, which:

- Prevents excess axle loading

- Reduces friction and wear

- Improves Boost control

Two-Stage Parallel Turbochargers for Diesel Engines

In our Two-Stage parallel systems, two turbos work in sequence, delivering significant gains in power and torque in engines typically 2.0L or bigger.

Two-Stage Serial Turbochargers for Diesel Engines

Garrett’s Two-Stage serial turbo for diesel compounds the benefits of turbocharging by using two turbos in a series arrangement. This helps improve transient performance, offers better low-speed torque and optimizes fuel efficiency in passenger and commercial vehicle applications. Auto manufacturers can use this technology to either downsize engines or increase performance.

Engine Range

Our variable geometry turbos for diesel engines are available in a full range of sizes. Mono-turbo setups work best with 1.3L to 4.5L diesel engines in passenger cars.

Ultra-Efficient Clean Diesel Platforms Can Benefit Greatly from Garrett’s Downsized, High-Temperature VNT Boosting Technology

Garrett’s sixth generation variable geometry turbo architecture (VNT) is helping auto manufacturers harness the performance potential of higher temperature diesel powertrains.