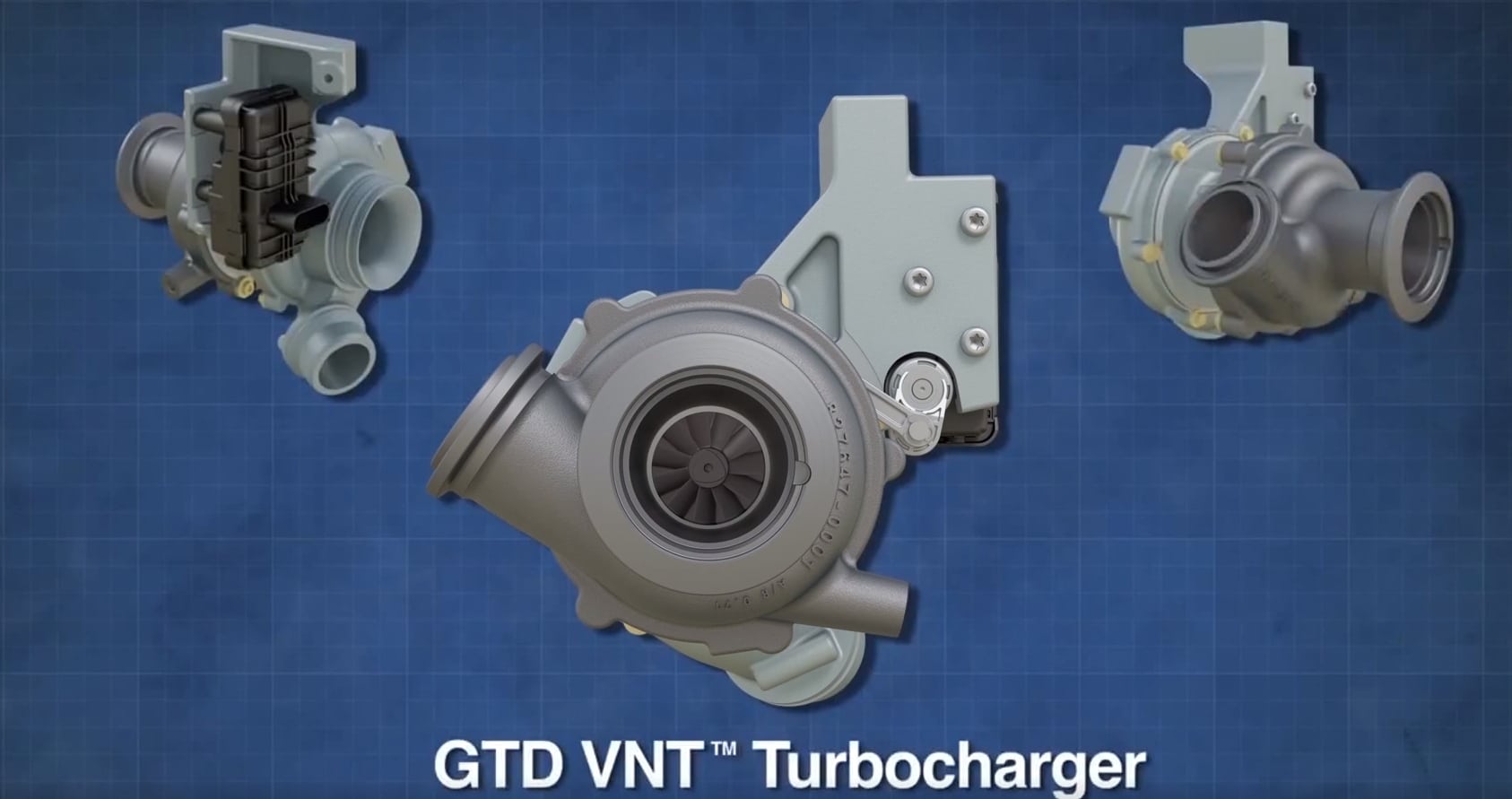

Performance & Reliability

Garrett turbo systems – from the renowned Variable Geometry Turbo (VNT) architecture to innovative Two Stage designs – leverage engineering advances in aerodynamics, materials, bearings and electric actuation to set new benchmarks for performance and reliability.

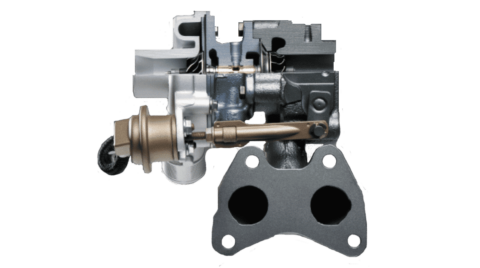

Small Wastegate Turbochargers for Diesel Engines

Our latest small wastegate turbos, with improved aerodynamics, provide a cost-effective route to fuel efficiency and emissions control without compromising performance. The compact design focuses on low-end torque and transient response and, with its lighter weight, offers packaging flexibility valued by automakers.

Variable Geometry Turbochargers for Diesel Engines

Garrett’s variable geometry VNT technology has been matched to more than 70 million diesel engines in the last three decades. The turbo’s advanced design helps manufacturers boost car and light commercial vehicle engine performance, increasing fuel efficiency, reducing emissions, enhancing driveability and improving packaging flexibility.

Two-Stage Parallel Turbochargers for Diesel Engines

Our Two-Stage parallel turbo for diesel engines was an industry first when we released it in 2006. Since then, it’s increasingly in-demand among auto manufacturers seeking enhanced performance, fuel efficiency, and emissions control.

Two-Stage Serial Turbochargers for Diesel Engines

Garrett’s Two-Stage serial turbo for diesel compounds the benefits of turbocharging by using two turbos in a series arrangement. This helps improve transient performance, offers better low-speed torque and optimizes fuel efficiency in passenger and commercial vehicle applications. Auto manufacturers can use this technology to either downsize engines or increase performance.