Enable Better Performance, Fuel Economy with Garrett’s Electric Compressor for Hybrid Vehicles

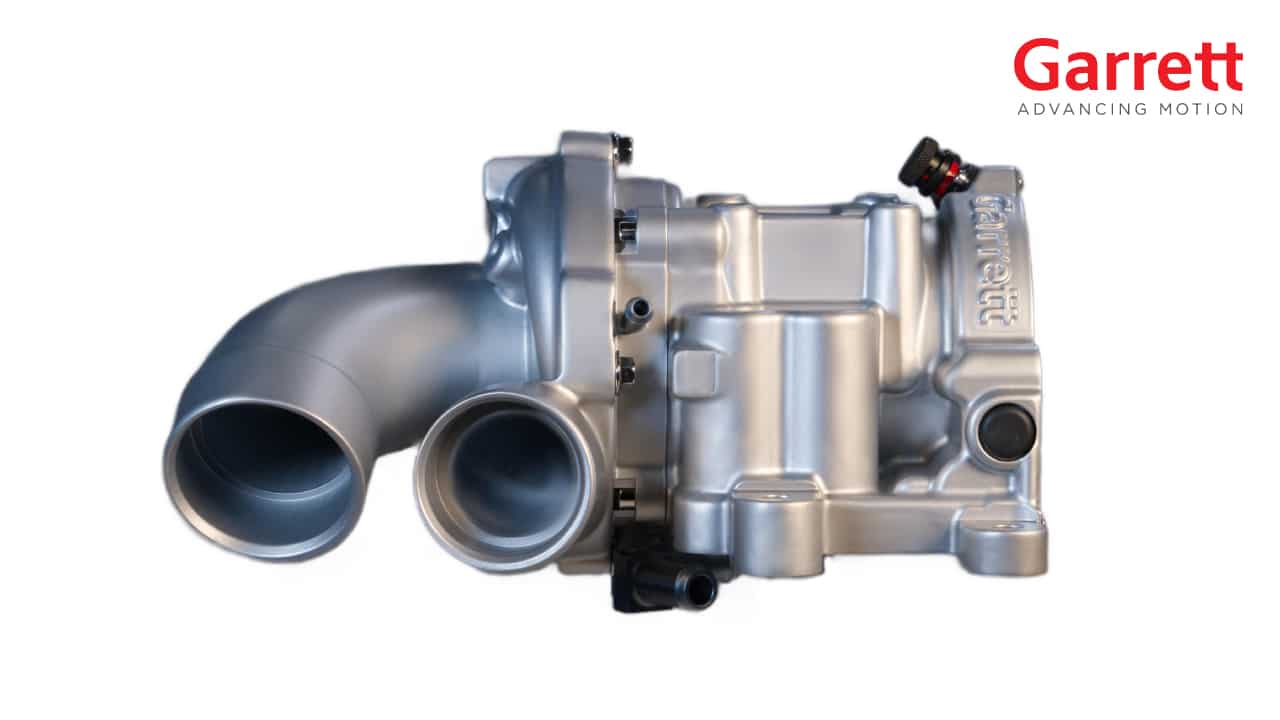

Garrett Motion Inc. An E-Compressor drives a centrifugal compressor with a high-speed electric motor to supply air to an internal combustion engine.

Garrett Motion’s next-generation electric compressor (E-Compressor) is one of the company’s latest developments in electric boosting technology. It further expands the company’s presence in the growing mild and full hybrid passenger vehicle segment.

An E-Compressor can be used alone or in combination with a turbocharger to electrify the boosting system and enhance the vehicles performance, while optimizing fuel economy and reducing exhaust emissions.

“Over the last several years we have invested heavily in our people, labs and manufacturing facilities to further expand our electrification and software expertise,” explains Craig Balis, Garrett Vice President and Chief Technology Officer. “Our new-generation and proprietary electric compressor dramatically improves transient response and steady-state, low-end torque, enabling advanced combustion strategies required to meet stringent emissions norms.”

The technology is compatible with both 48-volt systems on mild hybrids and 300-400-volt systems on full and plug-in hybrids. As such it further expands Garrett’s presence in the rapidly growing hybrid passenger vehicle industry, including SUVs.

E-Compressor Overview

In a full system Garrett’s E-Compressor is paired with a turbocharger to make an electrically assisted boosting system. Together they improve vehicle performance and fuel economy while helping to reduce emissions. The turbocharger is driven by otherwise wasted exhaust energy to provide the first stage of boost to the engine. The E-Compressor augments this with a second stage of boost using a high-speed electric motor to enable very fast acceleration of the compressor wheel. This “boost on demand” capability not only provides leading engine performance and responsiveness but can also enable advanced combustion strategies for future emissions requirements.

The next-generation E-Compressor provides more power and faster response in a smaller and lighter package than previous generations, further enabling engine performance and efficiency. Demonstrated benefits in different gasoline and diesel applications include 15% power density increase under full “Lambda 1” conditions, 10% torque density increase, and up to 20% reduction in NOx and soot emissions reduction. Furthermore, when paired with advanced approaches such as Miller combustion the next generation E-Compressor can provide up to 3% in fuel savings.

E-Boosting at Garrett

Both Garrett’s new E-Compressor and E-Turbo technology, which installs a high-speed electric motor directly on the turbocharger shaft, are compatible with 48-volt systems on mild hybrids or 300-400-volt systems on full or plug-in hybrids. These vehicles are increasing in demand among global consumers due to their high energy efficiency, performance, and relative affordability.

Growth in Electrified Powertrains

According to IHS, the production number of hybrid vehicles, which have powertrains equipped with a gasoline or diesel internal combustion engine in combination with an electric motor, is expected to more than double to approximatively 30 million in 2026, representing a third of the total global light vehicle production.

“Electrified hybrid powertrains are one of the fastest growing segments in the global automotive industry and create a compelling opportunity for Garrett’s expanding E-Boosting portfolio,” said Balis. “The utilization of our pioneering turbos and E-Boosting technologies on new hybrid systems sets new benchmarks in vehicle performance and is one of the most cost-effective solutions for OEMs to address strict environmental standards globally.”

Garrett teams are engaged in multiple OEM projects to provide E-Boosting solutions for their electrified powertrains, including hybrid and fuel cell vehicles.

“Our next-generation E-Compressor is designed with our own high-speed electric motor and advanced controls and is the latest demonstration of Garrett’s in-house capabilities in automotive engineering.,” Balis added. “Going forward, we will continue to invest in product innovations and new technologies consistent with our focus of remaining at the forefront of the propulsion of electrified vehicles.”

Click here to discover even more about Garrett’s E-Compressor technology.