The Future of HVAC is Oil-Free: Garrett’s Centrifugal Compressor for Low-GWP Refrigerants

As the world accelerates toward climate-conscious technologies, the cooling industry faces a pivotal challenge: delivering high-performance thermal management while cutting environmental impact. The path forward lies in low-GWP (Global Warming Potential) refrigerants, and in the technology that makes them viable at scale.

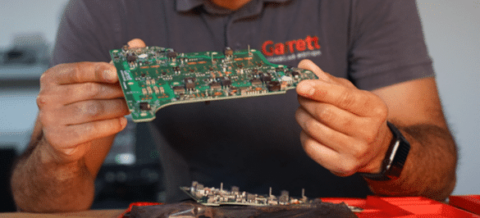

Garrett Motion is powering this transformation with its oil-free centrifugal refrigerant compressor, engineered specifically for use with low-GWP and natural refrigerants. Built on foil-bearing technology, this compact, oil-free solution helps OEMs meet global sustainability targets while enhancing system efficiency, safety, and long-term reliability.

Why Low-GWP Refrigerants Matter

Legacy refrigerants like R134a and R410a are being phased out due to their environmental footprint. Their replacements, HFOs (hydrofluoroolefins – e.g., R1234ze, R1234yf) and natural refrigerants like propane or ammonia, offer major climate benefits, but also introduce new technical demands, such as higher mass flow rates and stringent safety expectations.

Oil-lubricated compressors are poorly suited to handle these challenges. They increase flammability risk, complicate system design, and struggle with refrigerant compatibility.

The Garrett E-Cooling Advantage: Oil-Free, Reliable, and Future-Ready

Garrett’s centrifugal E-Cooling compressor delivers thermal performance without compromise, combining compact design with proven foil-bearing technology, and absolutely no oil.

- Oil-Free Architecture: Foil bearings enable frictionless, leak-free operation. No oil piping, no oil filters, no oil degradation.

- Natural Refrigerant Ready: Supports low-GWP and natural refrigerants, enabling sustainable designs and regulatory compliance.

- Lower Maintenance: Eliminates oil service routines, reducing both system complexity and lifetime costs.

- Compact & Powerful: Delivers up to 75 kW of cooling in a package up to 75% smaller than traditional systems.

- Lightweight Design: Up to 75% lighter, enabling easier installs and design flexibility for OEMs.

- Quiet Performance: Runs up to 10 dBA quieter, ideal for urban rooftops and acoustic-sensitive sites.

- Vibration Control: Over 90% less vibration than oil-lubricated alternatives, reducing refrigerant leaks and increasing lifespan.

- High-Speed Capability: The motor can operate at up to 160,000 RPM, ensuring rapid response and efficient load handling, all while remaining oil-free.

Backed by Garrett’s Engineering Heritage

Backed by Garrett’s Engineering Heritage With over 70 years of turbomachinery innovation, Garrett delivers proven expertise in foil-bearing technology, high-speed motors, fluid dynamics, and advanced power electronics. Our in-house design and production capabilities ensure reliable performance that meets the evolving needs of global OEMs and commercial infrastructure.

A Smarter, Safer, Sustainable Future

Transitioning to low-GWP refrigerants is no longer optional, it’s essential. But succeeding requires cooling technologies engineered for reliability, safety, and efficiency from the start.

Garrett’s oil-free centrifugal compressor is purpose-built for this next generation of HVAC systems. It enables:

- Compact installation in space-constrained environments

- Long-life operation with minimal maintenance

- Seamless compatibility with low-GWP and natural refrigerants

- Reduced carbon footprint and lower total cost of ownership

It’s not just a product. It’s a smarter way forward. Explore how Garrett can help you future-proof your thermal systems.