Understanding the Difference Between Electrified and Electric

Engineering Director Geoff Duff presents Garrett’s electrification strategy at the North American International Auto Show in Detroit in January, 2019.

“Electrification” has become a great, big, giant buzzword in the automotive industry as the global pursuit of cleaner more efficient energy imprints itself upon the vehicles of tomorrow.

Describing the engine in your car or truck used to be simple. In the U.S., you most likely described it by its size or the number of cylinders it had: a V8, V6, or perhaps as a peppy little inline-4. In Europe, more likely than not, it was a turbocharged diesel engine that was considerably smaller but ran for days and days on a single tank of fuel.

Today, we have a whole new language denoting EVs, BEVs, PHEVs, mild hybrids, full hybrids, series hybrids, micro hybrids and hydrogen fuel cells. There are more combinations every day it seems. If you are confused, you are not alone.

Garrett engineers and executives have been making the rounds in recent months to help explain how the world of automotive powertrains has gotten so complex, and why “electrified” and “electric” are two very different propositions for automakers, regulators and consumers all around the world.

Basic Setup

The engines we are familiar with are internal combustion engines with slightly different configurations between gas and diesel to account for the difference igniting the two types of fuel – spark for gas, and compression for diesel. Garrett has been helping automakers improve power and performance in these engines with its turbocharger technology for more than 65 years. In recent decades, global macros demanding greater fuel efficiency and reduced emissions have made turbocharging and engine downsizing a true no-compromise solution for nearly all vehicle types.

When automakers speak of “electrification” as a new development cycle, it is generally as a means of enhancing vehicle performance through one of two methods. The first is introducing electricity into powertrain configurations to create a hybrid between mechanical and electrical systems. In contrast, a battery electric vehicle (BEV) replaces a gas tank with a battery and replaces an internal combustion engine with an electric motor and inverter (controller).

Hybrids Are Coming

As research and development continue, electrified hybrid powertrains by all accounts represent the biggest growth opportunity. By 2025, global light vehicle production is expected to approach 110 million vehicles made per year. Industry analyst IHS is forecasting by 2025 that there will be 33 million hybrid cars or 30 percent of the global car population. With 76 percent of those using turbochargers (a percentage that is even greater than the accelerating penetration of turbos on internal combustion engines!) Pure electric vehicles – or BEVs — will also increase, but even aggressive industry estimates suggest only 5 to 10 percent of the global car population will be BEVs by 2025.

Turbocharging the Electrified Powertrain

Garrett started investing more than 15 years ago in electric boosting, in anticipation of the demand wave that is now forming. As the internal combustion engine of a hybrid needs to be operating at its peak efficiency, it still needs a turbocharger. We have two products that electrify the boosting system and can reduce CO2 emissions by up to 10 percent:

- Electric compressor – An e-compressor is a second distinct device used in combination with a traditional turbocharger. In a traditional turbo, a turbine wheel is driven by the energy derived from the vehicle’s exhaust. As this energy is applied to spin the turbine wheel, it is connected by a shaft to a second wheel, the compressor wheel, which then acts as intake fan to push and compact more air into the engine. An e-compressor replaces the “hot” turbine side of the turbocharger with a high-speed electrical motor. This electric control can improve the response time for the compressor wheel on the other end to match the needs of the vehicle as it drives. In doing so, there are fuel economy and emissions benefits. That electric compressor allows a second device to provide additional boost beyond what the turbocharger is doing and allows you to control the air with even more precision.

- Electric turbo — Another solution is to put a high-speed motor directly on the turbocharger shaft negating the need for a second device. Using electricity to accelerate the shaft also adds more control to the compressor wheel just as in an E-compressor, but with significant additional benefits. Integrating the electric motor into the turbo is not only beneficial in terms of complexity reduction and packaging, but the real benefit is that the excess energy not needed by the turbo can be used to create electrical energy to recharge the battery or drive the wheels. In this way, the role of the turbocharger is evolving into a key technology solution for sustaining hybrid vehicle powertrains at a systems level. The benefits of this include reducing the size of the battery and its cost and reducing the frequency of recharging (perhaps potentially eliminating.) Our first customer use of our technology in 2021 will include a consolidated solution comprised of the electric turbo, the controller and the required software.

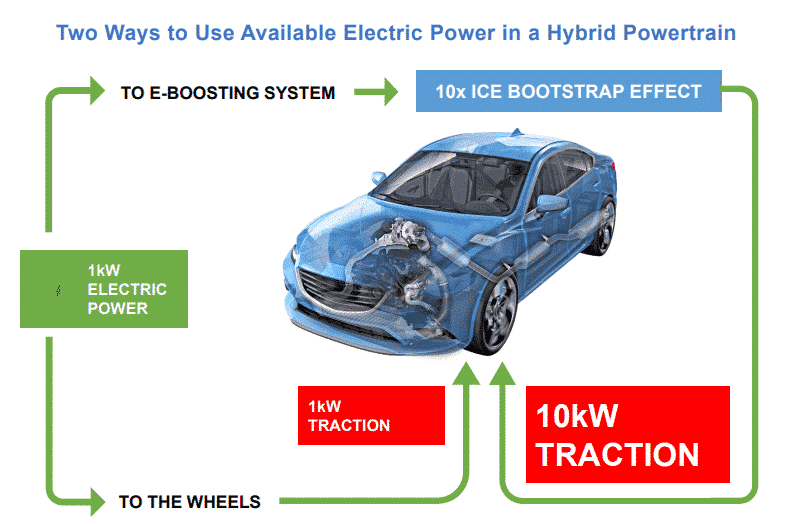

In fact, this bootstrapping effect, as Garrett refers to it, can be measured. Automakers taking 1 kW from the hybrid’s battery harvested from regenerative braking, could apply it electrically to the vehicle’s wheels to get an extra 1 kW of power and gain driving efficiency. Alternatively, applying that same 1 kW to accelerate the turbocharger would pump more air into the engine, thus allowing for more fuel into the engine and generating more power. In this case, documented lab tests show the 1 kW applied at the turbo yields 10 kW more power at the crankshaft of the engine. (* See NOTE below)

One More Solution: Hydrogen Fuel Cells

It’s still a long-term trend, but the potential for hydrogen fuel cells is really tremendous. A hydrogen fuel cell is just an electrochemical cell. By using pure hydrogen as a “fuel”, you get two products: electricity and pure water. It’s a zero-emissions device using electricity to power the electric motor in the vehicle. Unlike a BEV vehicle where the source of the electricity can be traced to fossil fuel-fed powerplants, this electric car is fueled by hydrogen.

Unlike BEVs which take some time to replenish, a hydrogen fuel cell vehicle has a tank like your current car that can be refilled in 3 to 5 minutes. And it also more closely mimics the range of an internal combustion engine vehicle allowing 300 to 400 miles per tank.

A fuel cell must also breathe air, and Garrett is already providing automakers with technology solutions to reduce the size and increase the efficiency of the hydrogen fuel cell stack. Our two-stage electrical compressor was first launched in 2016 with Honda on its Clarity Fuel Cell vehicle. It is the most advanced technology in this space, running high-speed electric motors and power electronics. Per Garrett’s mission statement to serve the unmet needs of the industry, it also has technologies that are differentiated from any other available solution in the industry like air foil bearings. This design eliminates any oil in the compressor and the associated risk of contamination for the fuel cell.

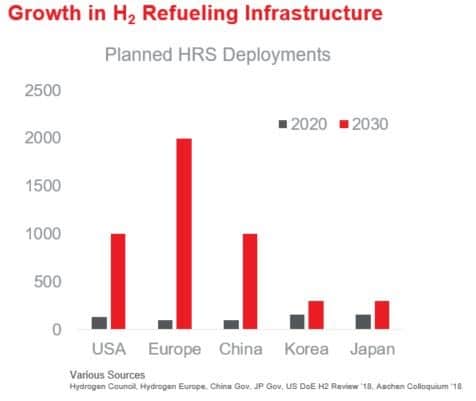

Today, Garrett is engaged in more than 10 OEM projects to develop electric compressors for hydrogen fuel cell vehicles. Industry development also requires government support. After China’s financial subsidies for new energy vehicles completely disappear in 2020, fuel cell vehicles will become the only new energy vehicle technology routes that receive subsidies.

As governments invest in hydrogenation station facilities, the situation of effective hydrogen supply will rapidly improve. We already see this happening in China, where hydrogen energy and fuel cell technology is included in the government’s 13th Five-Year National Science and Technology Innovation Plan which aims to develop leading technologies for China’s industrial development revolution.

Looking Ahead

As we look forward, Garrett – Advancing Motion will continue to invest in both hardware and software as key components in the development of high-performance powertrain and vehicle systems. Systems that are attractive to customers and reflective of increasingly stringent regulations around the world.

Our world-class technical solutions are helping to drive a new era in hybrid electrification and fuel-cell powertrains. These innovations enable our customers to set new benchmarks in vehicle performance while vastly improving fuel efficiency and exhaust emissions levels. Garrett is committed to technical engagement to tap into opportunities for things like hybrid and hydrogen applications in vehicles and transportation systems, ultimately helping to reduce negative environmental effects.

* NOTE: While burning more fuel does not increase efficiency, the ability for the engine to make an extra 10kW of power on demand (which is infrequent) allows for a smaller engine design. This smaller engine does translate to measurable fuel economy savings on a drive cycle-weighted basis.