Increased Power & Efficiency in a Compact Design

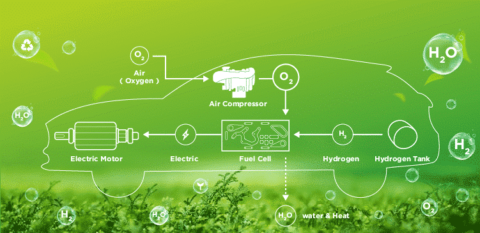

Garrett has been at the cutting edge of fuel cell innovation for more than 40 years. We launched the auto industry’s first fuel cell production car application in 2016, and now our global footprint and leadership in electrification systems – including E-Turbo – is helping drive worldwide adoption of this zero-emissions technology. Garrett’s high-pressure ratio electric compressors significantly increases the power density of Proton Exchange Membrane (PEM) fuel cells while reducing compressor noise, allowing this clean energy technology to be applied to modern vehicles.

Discover our solutions for

Passenger Vehicle

Sport Utility Vehicle and Pick-up

Light and Medium Size Commercial Vehicle

Heavy-Duty and Off-highway Vehicle

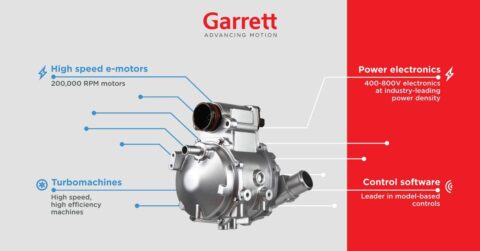

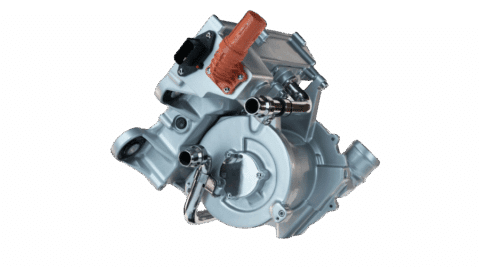

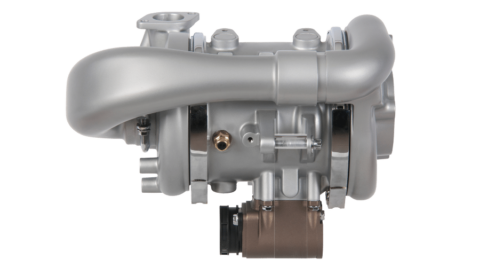

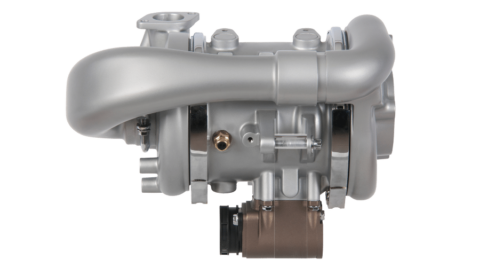

Fuel Cell Compressor Gen3

Unlock peak performance for fuel cell applications with Garrett’s Fuel Cell Compressor Gen3. This new generation is offering higher efficiency, compact design, and an integrated inverter.

Modular FC compressor: Optional Turbine

This generation of product combined the knowledge of our base turbocharger business for aerodynamics, our new high-speed motor experience, and oil-free bearing experience. Capable of more than 150,000 RPM, our fuel cell compressor delivers leading performance and efficiency in a compact size.

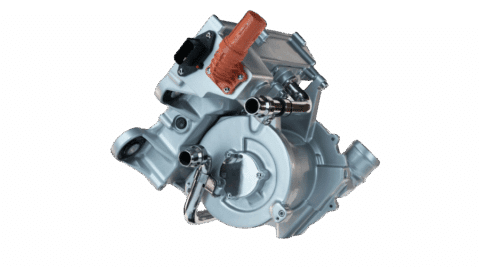

Two Stage Electric Compressor

Our Two-Stage electric compressor boosts fuel cell stacks to higher pressures and flows, significantly improving efficiency and power density and enabling downsized packaging to fit and drive the electric powertrains of regular-sized vehicles.

The result is improved driving performance – and a major step on the pathway to a zero-emissions future.

Latest Fuel Cell videos

Garrett Fuel Cell Innovation Timeline

INCREASED POWER & EFFICIENCY

Why do customers choose us?

Do you have a Fuel Cell project?

OUR SUCCESS STORIES

EXPAND YOUR FUEL CELL KNOWLEDGE

Have a Question?

Connect with Us

* These fields are required.