Accessing the Knowledge Center effectively requires a simple, one-time registration.

Have you ever wondered what that A/R number means on a turbocharger? Why is there one on the compressor side and why is there one on the turbine side and what does it all mean? This write up is here to explain the difference an A/R makes on performance and show dyno graph overlay data for horsepower and torque to analyze how the changes affect engine response.

What is A/R?

A/R stands for Area over Radius. It is defined as the inlet (or, for compressor housings, the discharge) cross-sectional area divided by the radius from the turbo centerline to the centroid of that area. Huh?

A/R Simplified: As an example, think of A/R as a straw and you are trying to blow air through it. The smaller the A/R, the smaller the diameter of the straw, or air passage. If you take a coffee straw and try to blow air through it, you quickly reach the flow limits for volume and velocity of the straws air passage. You may have also noticed pressure in your cheeks as you were not able to get the air through the straw fast enough. In turbo talk we call that back pressure which can be really bad for an engine especially in the quest for higher horsepower. Finding a way to decrease engine backpressure helps promote flow from the cold side of the engine (intake) to the hot side (exhaust). More Flow = More Horsepower. Now imagine the same example with a larger diameter straw. The straw’s larger air passage can flow more air and you are able to exhaust your breath easier without as much pressure (back pressure) in your cheeks. This is very similar to how an engine and turbo work together. The engine produces exhaust air that flows through the turbine housing and propels the wheel assembly. So, selecting the right size A/R for your turbine housing is very critical to reaching the optimum performance for your build.

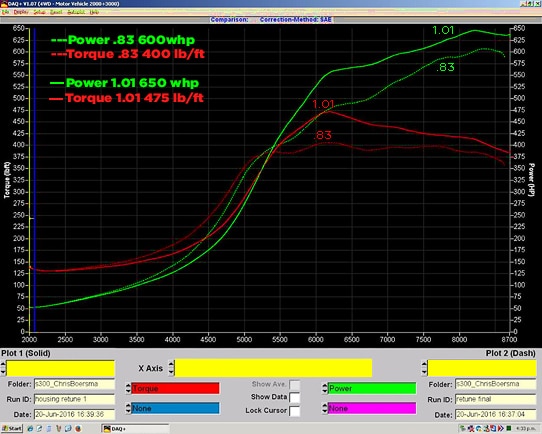

Garrett sponsored Time Attack racer Chris Boersma performed a similar test with his 1.9L Honda Civic. Chris was using the GTX3076R Gen II turbo with a divided v-band .83 A/R housing which netted 600whp and 400ft/lbs of torque. This housing also delivered good mid-range power and response for on track performance. For a complete build breakdown on Chris’ Civic click this link.

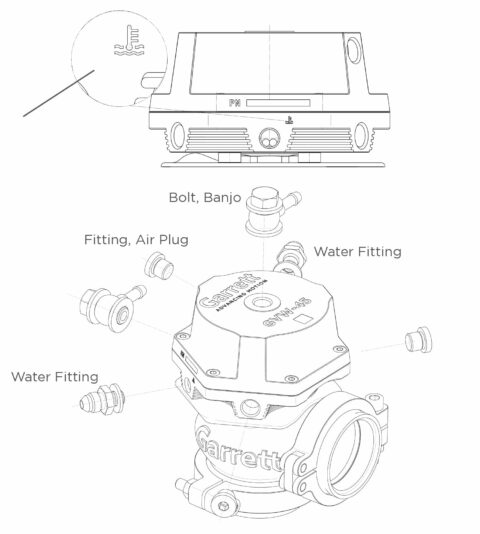

The team decided to change to the 1.01 A/R turbine housing to increase horsepower as the competitor’s cars were making between 50 and 100whp more than they did. Thankfully, turbine housing changes are simple and require no changes to manifold piping given you stay with the same inlet flange, so Boersma figured it was worth a shot to see how it all worked.

Switching to the larger 1.01 A/R turbine housing, Boersma picked up 50whp and 75ft/lbs of torque! There was a trade off in spool moving to the larger housing. Looking at the dyno graph you can see the larger A/R changed the shape of the power and torque curves. Full spool moved from 5250rpm to almost 6000rpm, and they were able to carry the power higher in the RPM range.

You can see the shape of the graph is different with the larger housing. The .83 A/R housing had a much smoother transition into power, where the 1.01 A/R has a steeper curve which translated to a much more aggressive feel on track. You can also see how the .83 A/R power curve dips at the end of the pull which could indicate the air volume limits of that housing and the need to utilize a larger A/R.

Boersma’s Input On-Track Response

Boersma says, “As a driver I had to change the way I drove with the larger housing otherwise you could be a in a situation where the tires were wanting to break loose at that transition point into power. Overall, we found the larger housing was best suited for larger faster tracks where there were fewer low speed corners. With our limited ECU we didn’t have the ability to control boost in lower gears or have traction control at our disposal which would have made this setup a lot more effective at lower speed.”

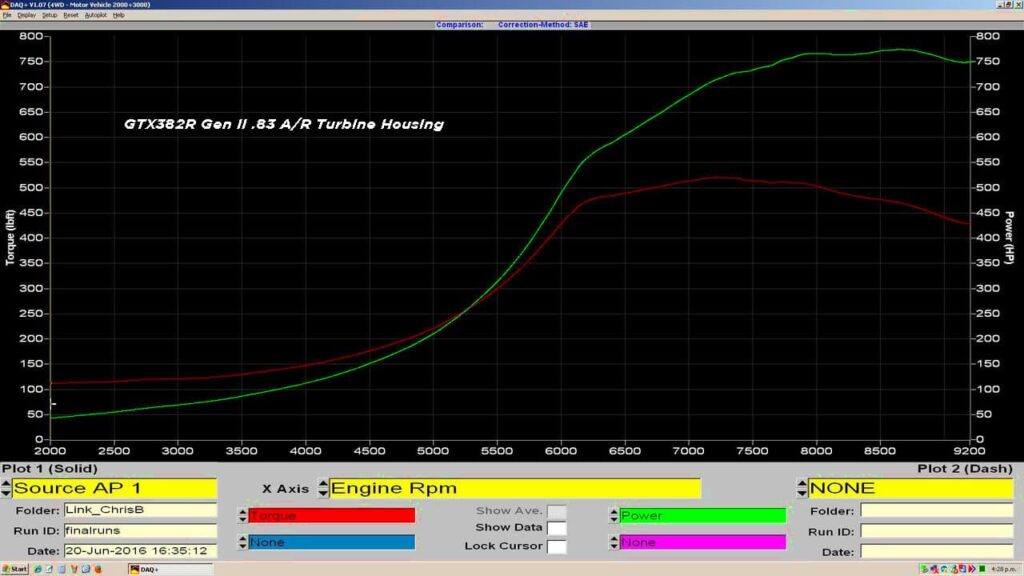

“Additionally, The 1.01 A/R housing really made the GTX3076R Gen II feel and operate more like its GTX35 brother. Looking at our graph from our GTX3582R Gen II turbo with the .83 A/R housing this year you can really see how close the power bands look. The GTX3582R Gen II is still a little later to spool, but the difference is pretty small, however it’s able to make a lot more power and carry that power even further up top, says Chris.”

In Summary

Overall our experimentation with different housings showed us that smaller turbos really can be effective at making big power, but there’s always a trade-off and that sometimes it makes more sense to run a larger turbo with a smaller housing than a smaller turbo with the larger housing. For a complete build breakdown on Chris’ Civic click this link.

Additional Examples

It’s important to note that every engine setup will react differently. You can see a similar test with a Garrett G25-660 and the .72 A/R vs the .92 A/R housings on Speed Academy’s Abandoned STI video. In this example the turbine housings did not make as significant of a difference.

Rob Dahm shows the difference a turbine housing makes on his 3 Rotor RX7.

Rob tests the difference a 1.44 A/R turbine housing makes vs a 1.15 A/R turbine housing on his RX7. The results help lower back pressure with minimal effect on boost response.