Accessing the Knowledge Center effectively requires a simple, one-time registration.

Garrett G-Series Turbochargers

Garrett G-Series turbochargers are the latest generation of racing and performance turbochargers from Garrett Advancing Motion. The G-Series product line was engineered for 1.4L – 12.0L engine displacements and can support from 300 – 3000 flywheel horsepower. This is a very broad range consisting of over 30 turbochargers. The addition of G47 and G50 added six new supercores! So how do you know what turbo is right for you?

Selecting A Turbocharger

Selecting a turbocharger is a very complex process that requires lots of engine input and operating data if you want to get an OEM level match. However in the performance market segment, most teams do not log any data at all. Garrett designed a tool called Boost Adviser to help walk enthusiasts through several questions that will narrow the available options and perform a compressor match. Check it our here.

If you don’t want to go through the steps today, you can visit Boost Adviser later, but to find a turbo match you need to know two key inputs. Flywheel horsepower and Engine displacement. These two inputs will narrow your search options drastically. In this article we are going to look at the differences between G-Series G47 and G50 turbochargers.

Garrett G-Series G47 Turbochargers

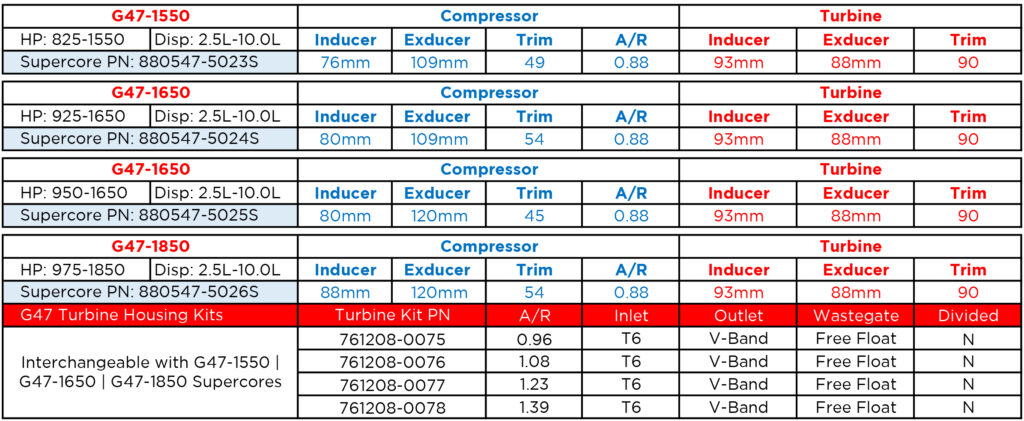

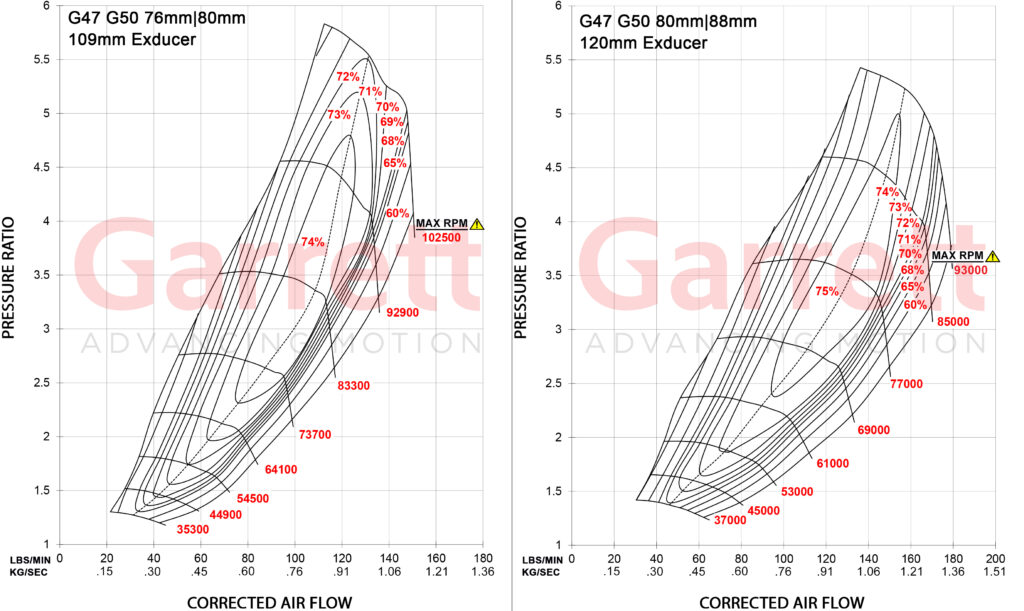

In the chart below you can see the specs for each of the four G-Series G47 supercores. There are three compressor inducer sizes: 76mm | 80mm | 88mm and two compressor exducer sizes: 109mm | 120mm. Each one has its own flywheel horsepower range and the peak horsepower is used to distinguish the supercore from the others.

The G47 turbine wheel supports 2.5L – 10.0L engine displacements. The inconel turbine wheel has a 93mm inducer and an 88mm exducer making it a 90 trim wheel. All of the G-Series G47 turbochargers use the same turbine wheel which means only the G47 turbine housings can be used on these supercores. This also allows enthusiasts to swap supercores if more or less power is needed or if class spec racing called for specific compressor sizes.

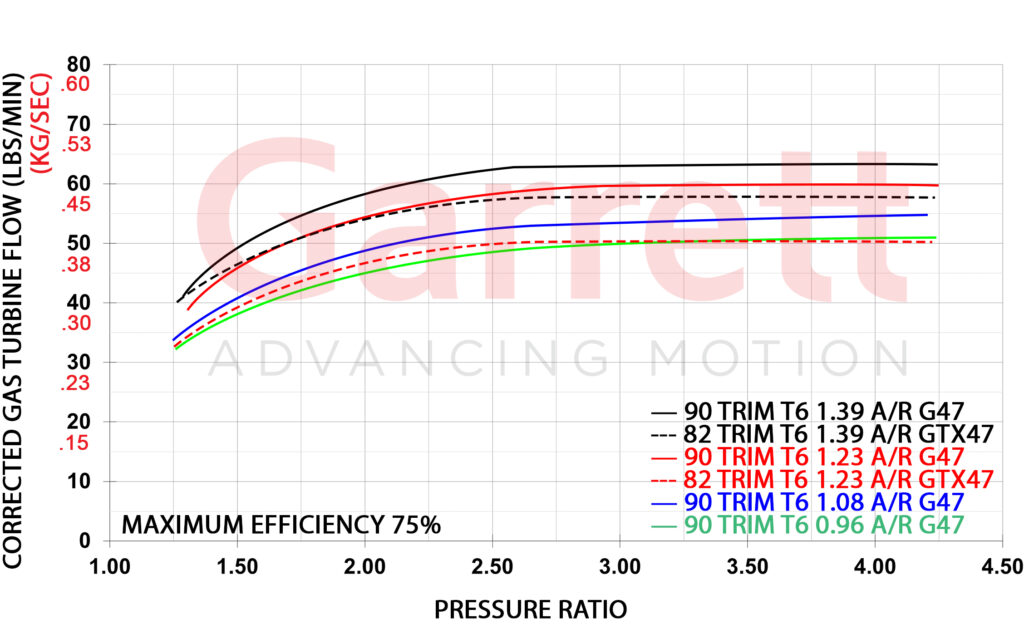

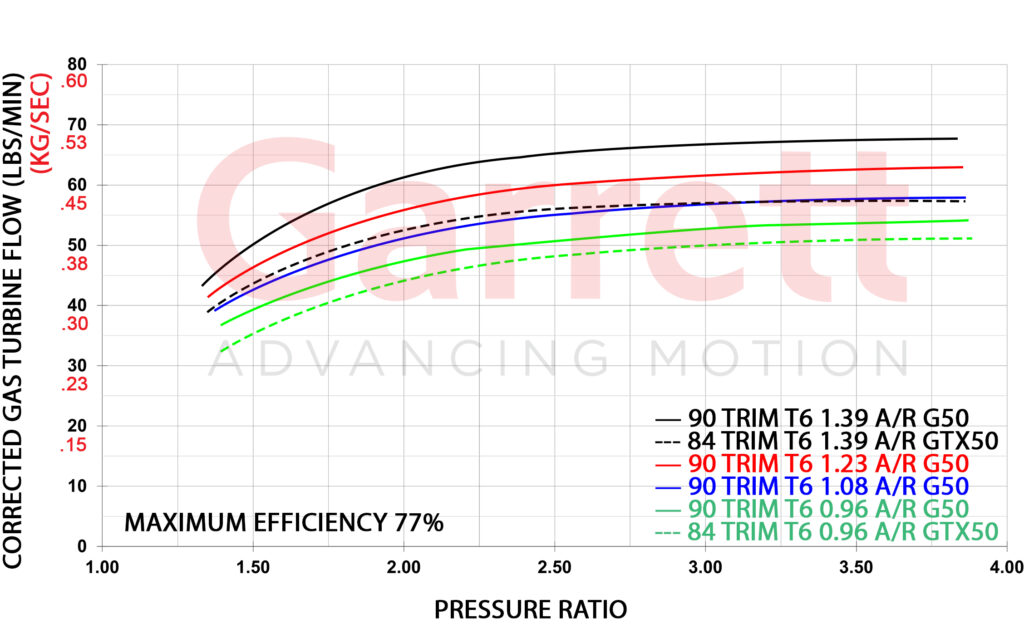

G47 Turbine Flow

G-Series turbine aero and flow is one of the most notable features for G-Series turbochargers. The G47 turbine wheel flows up to 20% more exhaust volume than the GTX47 wheel. The turbine wheel will provide up to 9% quicker spool (estimated by flow, efficiency, and inertia). The exhaust flow chart below shows the flow range for each of the four A/R and the dashed lines are comparisons from the GTX47 test data. G47 turbine housings are cast from stainless steel, with T6 inlet flanges and V-band outlet flanges.

Garrett G-Series G50 Turbochargers

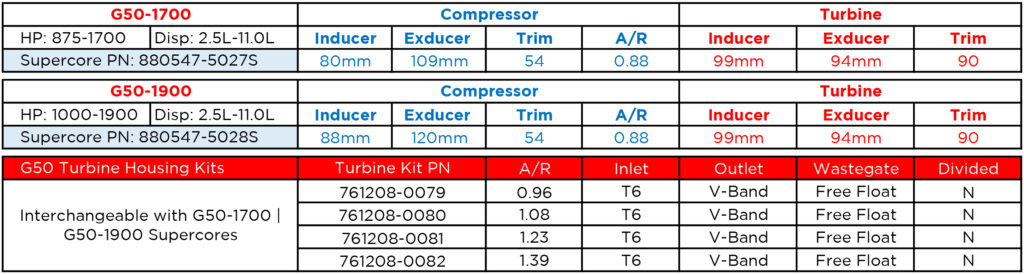

In the chart below you can see the specs for each of the two G-Series G50 supercores. There are two compressor inducer sizes: 80mm | 88mm and two compressor exducer sizes: 109mm | 120mm. Each one has its own flywheel horsepower range and the peak horsepower is used to distinguish the supercore from the others.

The G50 turbine wheel supports 2.5L – 11.0L engine displacements (+1.0L compared to G47). The inconel turbine wheel has a 99mm inducer and an 94mm exducer making it a 90 trim wheel. All of the G-Series G50 turbochargers use the same turbine wheel which means only the G50 turbine housings can be used on these supercores. This also allows enthusiasts to swap supercores if more or less power is needed or if class spec racing called for specific compressor sizes.

G50 Turbine Flow

G-Series turbine aero and flow is one of the most notable features for G-Series turbochargers. The G50 turbine wheel flows up to 23% more exhaust volume than the GTX50 wheel. The turbine wheel will provide up to 12% quicker spool (estimated by flow, efficiency, and inertia). The exhaust flow chart below shows the flow range for each of the four A/R and the dashed lines are comparisons from the GTX50 test data. G50 turbine housings are cast from stainless steel, with T6 inlet flanges and V-band outlet flanges.

G-Series Compressor Flow G47 G50

G-Series G47 and G50 utilize the same compressor wheel, aero, and compressor housing as the GTX47 GTX50 Gen II turbochargers. The G-Series turbine wheel is better suited with the high flowing GTX Gen II compressor wheel making this a high efficiency, high flowing turbo from both ends.

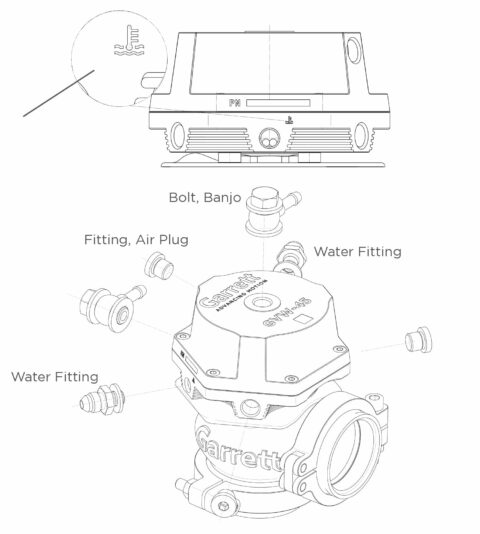

Center Section And Rotating Group

The compressor stage is mated to a new lightweight aluminum center housing and backplate. G-Series G47 and G50 turbochargers have a ceramic ball bearing cartridge. These turbochargers are oil cooled and do not have water cooling ports.

These are many of the new features you will find on the G47 and G50 large frame turbochargers. For more information including pricing please contact an authorized Garrett Performance Distributor.