On May 16-17 2023, Garrett Motion will be at the 15th International Conference on Turbochargers and Turbocharging, in London, presenting two new technical papers.

Technical Papers

“Secondary Air Injection with E-Boosting Devices”

Future emission norms will focus on reducing cold start emissions of gasoline engines. One promising solution is to use secondary air injection (SAI). However, current SAI systems are not powerful enough to operate against high exhaust back pressure.

Read this paper, you will learn about how Electric boosting products, such as E-Compressors and E-Turbos, can overcome this limitation. These products can provide SAI for cold start emissions, while also improving engine efficiency and reducing emissions under normal operation.

Speaker: Surya Kiran Yadla, Garrett Motion

“Development of Low Nickel Austenitic Stainless Steel for High Temperature Gasoline Turbochargers”

A new low-nickel austenitic stainless steel has been developed for use in turbine housings of turbochargers for gasoline applications.

Download this paper, and you will learn more about the new steel, which is made with nitrogen that acts as a strong austenitic stabilizer and reduces the need for nickel. This makes the new steel more cost-effective than traditional high-nickel stainless steel. The new steel was developed using an integrated computational materials engineering (ICME) methodology, which combines computational and experimental techniques. It has been tested up to 1050°C gas temperature under severe thermal shock loading conditions and compared with existing high-nickel conventional steels. The results show that the new steel is a promising alternative solution providing both better performance and lower cost for high temperature turbocharger applications.

Speaker: Ragupathy Kannusamy, Garrett Motion

Publisher: Institution on Mechanical Engineers

Publication date: 16 – 17 May 2023, at the 15th International Conference on Turbochargers and Turbocharging, Twickenham Stadium, London

TECHNOLOGIES ON DISPLAY

Electric Compressors for Fuel Cell Electric Vehicles

Our electric compressors boost fuel cell stacks to higher pressures and flows, significantly improving efficiency and power density and enabling downsized packaging to fit regular-sized vehicles.

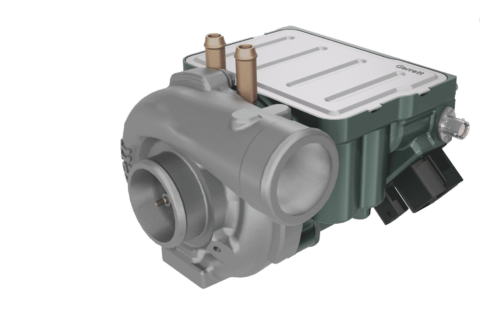

48V Electric Compressor Hybrid Vehicles

Our electric compressor can deliver unmatched power density through superior aerodynamics and electrical design, helping automakers achieve the diesel and gasoline powertrain efficiency required to meet stringent emissions standards.

Hydrogen Internal Combustion Engine

Garrett’s expertise and innovative technologies enable OEMs to leverage the fuel benefits of hydrogen on a turbocharged internal combustion engine.

Electric Turbo Innovation

Award-Winning Electrified Turbos (E-Turbos) show exciting potential to improve performance and fuel economy, with all fuels (gasoline, diesel, CNG, E-Fuels & and even H2) in both light & commercial vehicles.

Variable Geometry Turbo for Gas Engines

Garrett’s variable geometry turbos (VNT) for gas engines are optimized for the future of auto innovation. They use an advanced design—enhanced with all-new aerodynamics and materials—to achieve cost-effective, best-in-class performance and fuel economy.