Turbo Lag: Causes, Effects and Solutions

In this article, we’ll be explaining what Turbo Lag is, covering the causes, effects, and how you can solve this issue by simply choosing a genuine Garrett product for

Learn more

In this article, we focus on how turbos help transform engine performance by injecting compressed air into the combustion process and how intercoolers amplify this advantage.

Turbochargers unleash the power of compressed air to help propel vehicles to unprecedented levels of performance. Turbos, together with intercoolers, enable engine boosting systems to deliver more power, improve fuel efficiency, lower emissions and deliver a better driving experience.

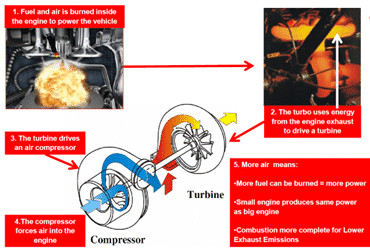

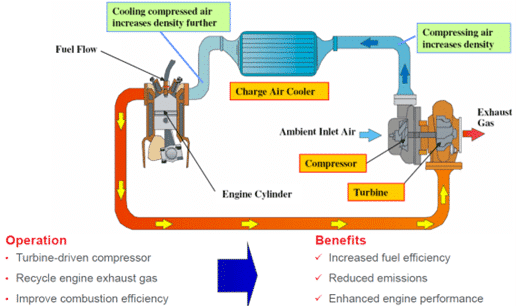

In a turbo, exhaust gases drive a turbine which is connected on a shaft to a compressor wheel, which in turn draws in and pressurizes ambient air. This compressed air is forced into the engine’s intake manifold, creating a mix of fuel and dense air that enhances combustion efficiency and increases engine performance.

Learn more about the compressor wheel here.

Compressed air pressure is typically measured in pounds per square inch (psi) or bar. The exact pressure delivered by the turbo can vary widely based on several factors, including the engine’s design, the size and specification of the turbocharger, and the desired performance characteristics.

In many automotive applications, turbocharged engines can produce boost pressures ranging from approximately 8 psi (0.55 bar) to 20 psi (1.38 bar) or even higher in aftermarket vehicle modification projects and high-performance applications.

Typical atmospheric pressure at sea level is approximately 14.7 psi (1 bar), which is equivalent to 1 atmosphere (atm) or 101.3 kilopascals (kPa). The turbocharger’s boost is made available because the compressor creates a pressure differential, increasing the air pressure above atmospheric levels.

Depending on the turbocharger size, design, and engine speed, this compression can happen extremely quickly. Some Garrett turbos can spin at speeds exceeding 300,000 revolutions per minute (RPM) (smaller TCs spin faster than larger ones), compressing the air almost instantaneously as it enters the compressor housing. When mixed with fuel, this pressurized air creates a more efficient combustion process, generating increased power and performance for the vehicle.

Compressing air generates heat. The exact temperature varies, depending on factors like the boost pressure, engine speed, and turbocharger efficiency, but in some cases, this temperature can be well above 200 degrees Celsius (392 degrees Fahrenheit). Air temperatures at this level will inhibit the combustion process and this is where intercoolers come in.

Intercoolers, located between the turbo and the engine cylinders, cool the compressed air, ensuring that it enters the engine at an optimal temperature for combustion. Critically, this cooling process serves to increase air density still further, forcing more air into the engine to optimize combustion efficiency. This is the core principle behind engine downsizing widely adopted by automakers to improve performance and reduce emissions.

Intercoolers can be seen as the overlooked heroes of compressed air. They transform potential thermal energy losses by balancing temperature, enhancing air density and gifting the engine increased power and efficiency.

Intercoolers offer several benefits when used in turbocharged engines:

Power Amplification:

Intercoolers amplify the magical attributes of compressed air. Through their cooling prowess, intercoolers optimize the air-fuel mixture to make more oxygen molecules available for combustion.

This leads to improved power and torque output from the engine.

Prevention of Detonation:

Lowering the air intake temperature also reduces the risk of detonation or ‘knocking’ in the engine. Detonation can be damaging and inefficient, so intercoolers help ensure a smoother and more productive combustion process.

Enhanced Fuel Efficiency:

Cooler and denser air allows for more precise control of the air-fuel mixture, which can improve fuel efficiency. This can result in better miles per gallon (MPG) or kilometers per liter (km/L).

Are intercoolers necessary?

On highway vehicle applications – PV CV & LCV* – intercoolers are essential components in turbocharged engines because they optimize the engine’s performance, efficiency, and reliability.

*(Passenger, commercial, light commercial vehicles)

Without intercoolers, the intense heat resulting from compressing air created via the turbocharger would compromise engine performance by allowing hot, less dense air to enter the engine, diluting the oxygen content and stifling combustion efficiency. Intercoolers intervene by effectively cooling the intake air, making it denser, and thus ensuring that the engine receives an optimal air-fuel mixture. This results in an immediate and tangible increase in power and torque output.

As such, intercoolers play a vital role in enabling the role of the turbo in maintaining consistent engine performance, reducing the risk of ‘knocking’, improving fuel efficiency, lowering emissions, and helping safeguard powertrain reliability.