Garrett’s High-Speed, High-Power Density E-Powertrain Advances the Future of Motion

In the fast-changing world of electric vehicle (EV) technology, Garrett has once again demonstrated its expertise by unveiling a revolutionary high-speed, high-power density Electric Powertrain. This innovative solution was first introduced to the public at the 2025 Shanghai Auto Show and further detailed in a technical paper at the 2025 Vienna Motor Symposium. It leverages advanced high-speed motor technology to deliver a significant step-change in Electric Traction Drives performance and compactness, setting new industry standards. It has already received a first series production order to co-develop and manufacture advanced E-Axle systems for heavy-duty trucks with HanDe, one of China’s leading axle manufacturers. The official signing took place at the Shanghai Auto Show – an important milestone that strengthens our growing presence in commercial vehicle electrification.

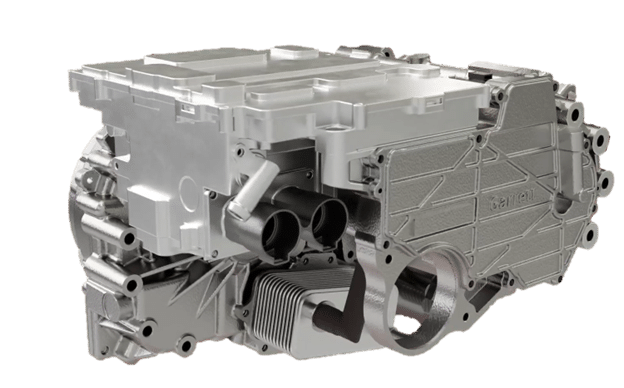

Garrett’s E-powertrain – which consists of integrated electric motor, inverter and gearbox – is a direct result of the company’s extensive expertise in high-speed rotating machinery. The system boasts industry-leading power density and achieves up to an overall 40% reduction in weight and size compared to industry references, while maintaining exceptional noise, vibration and harshness (NVH) performance. This remarkable achievement is further enhanced by a drastic reduction in the need for sensitive materials such as copper and rare earth elements, with an average reduction of ~30% compared to market references.

Garrett’s E-powertrain portfolio is scalable, covering a wide range of power, with both 400V and 800V options. It includes high-speed motors up to 35,000 rpm, high switching frequency inverters and a specially designed high ratio gear reducer. This comprehensive approach, now at B-sample status, is suitable for regular cars, sports cars, SUVs and even heavy-duty vehicles.

For example, the engine design focuses on balancing electromagnetic performance with mechanical and thermal compliance. The use of permanent magnet synchronous motors spinning from 30,000 rpm to 35,000 rpm allows for a lower torque requirement at the motor output shaft, resulting in a motor with reduced size and weight. This design not only reduces key cost drivers, but also improves sustainability by minimizing the use of expensive and sensitive materials.

The inverter, on the other hand, addresses the challenges associated with high-speed applications by balancing system efficiency and NVH (noise, vibration, and harshness). High switching frequency is essential to ensure the controllability of the electrical machine at high speed and to provide improved motor efficiency. Garrett’s innovative control methods, including variable switching frequency, discontinuous pulse width modulation (PWM), and optimal pulse pattern (OPP), optimize the trade-off between switching losses and total harmonic distortion (THD).

Gearbox design also plays a critical role in the overall performance of the electric powertrain. A high gear ratio (~23:1) ensures that the high-speed concept is not limited to sporty vehicles with high top speeds. The simplicity of the gearbox architecture: two-stages parallel lay shaft design and the attention brought to gears design offer significant advantages in power density and NVH (Noise, Vibration, and Harshness), while ensuring high efficiency. In addition, the splash lubrication system minimizes churning losses and ensures proper lubrication of gears and bearings.

Garrett’s high-speed electric drivetrain is not only about performance, but also about sustainability. By significantly reducing the amount of material required for production, the e-powertrain concept helps reduce greenhouse gas emissions. The design also incorporates measures to facilitate remanufacturing and recycling, further enhancing its sustainability credentials.

Garrett’s high-power density E-powertrain is a game changer in the electric vehicle powertrain market. By leveraging its expertise in high-speed motors and power electronics, Garrett has developed a solution that offers unparalleled power density, uncompromised efficiency and superior sustainability.