Accessing the Knowledge Center effectively requires a simple, one-time registration.

Turbo Oil Supply & Drainage

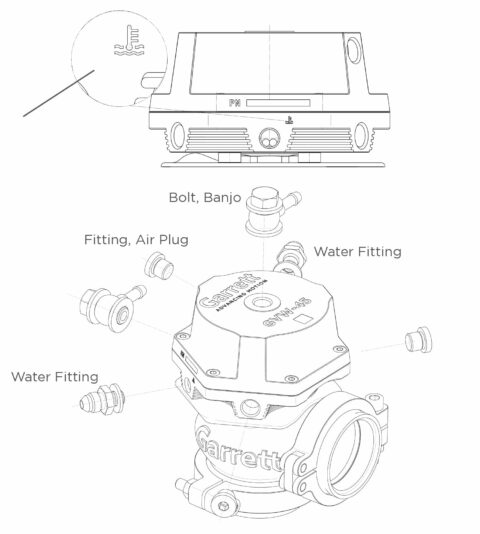

Ball Bearing Turbo

An oil restrictor is recommended for optimal performance with ball bearing turbochargers. Oil pressure of 40 – 45 psi at maximum engine speed is recommended to prevent damage to the turbocharger’s internals. In order to achieve this pressure, a restrictor with a 0.040” orifice will normally suffice, but you should always verify the oil pressure entering the turbo after the restrictor to ensure the components function properly. Recommended oil feed is -3AN or -4AN line or hose/tubing with a similar ID. As always, use an oil filter that meets or exceeds the OEM specifications.

OIL LEAKAGE SHOULD NOT OCCUR ON A PROPERLY FUNCTIONING SYSTEM IF RESTRICTOR IS NOT USED UNLESS THE SYSTEM PRESSURE IS EXCESSIVELY HIGH.

There are many products to help you achieve the recommended oil pressure to your turbo. Oil restrictors are threaded into the oil inlet and slow the oil feed based on the diameter of the orifice. G25 | G30 | and G35 turbochargers come with an oil restrictor and water fittings.

There are also oil pressure regulators like the Turbosmart ORP T40. This product can be mounted remotely, and can deliver a constant 40 PSI for nearly any engine and takes the guess work out of finding the correct restrictor.

Journal Bearing Turbo

Journal-bearings function similarly to rod or crank bearings in an engine – oil pressure is required to keep components separated. An oil restrictor is generally not needed except for oil-pressure-induced leakage. The recommended oil feed for journal bearing turbochargers is -4AN or hose/tubing with an ID of approximately 0.25”. Be sure to use an oil filter that meets or exceeds the OEM specifications.