Accessing the Knowledge Center effectively requires a simple, one-time registration.

Calculating the Correct Charge Tubing

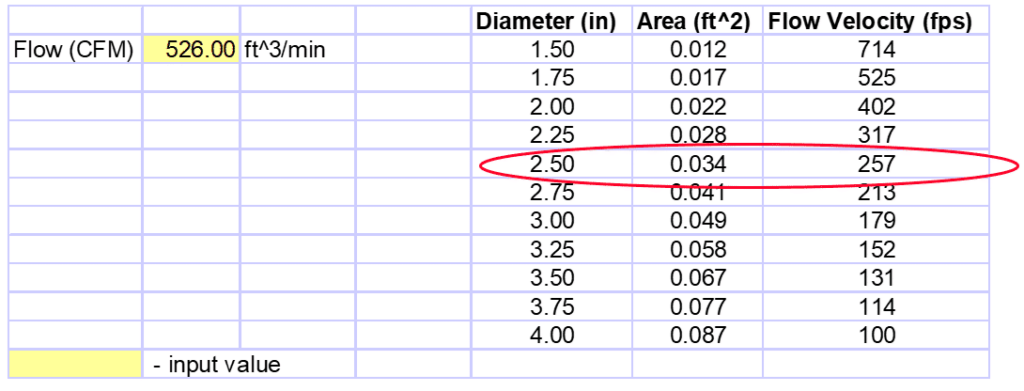

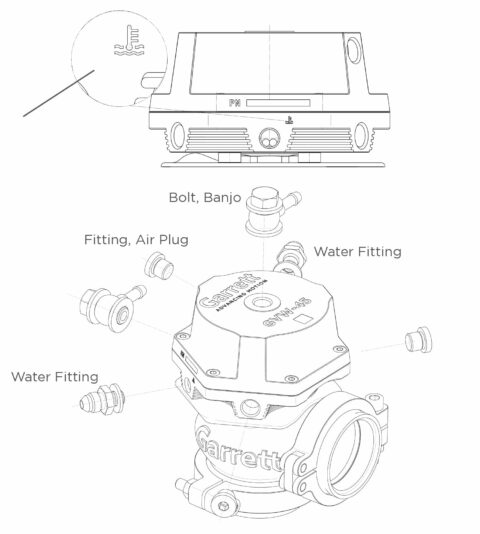

The duct diameter should be sized with the capability to flow approximately 200 – 300 ft/sec. Selecting a flow diameter less than the calculated value results in the flow pressure dropping due to the restricted flow area. If the diameter is instead increased above the calculated value, the cooling flow expands to fill the larger diameter, which slows the transient response. For bends in the tubing, a good design standard is to size the bend radius 1.5 times greater than the tubing diameter. The flow area must be free of restrictive elements such as sharp transitions in size or configuration.

For our example: Velocity (ft/min) = Volumetric Flow Rate (CFM) / Area (ft²)

• Tubing Diameter: velocity of 200 – 300 ft/sec is desirable.

Too small a diameter will increase pressure drop, too large can slow transient response.

• Velocity (ft/min) = Volumetric Flow rate (CFM) / Area (ft2)

Again, for twin turbo setups, divide the flow rate by (2).

Charge tubing design affects the overall performance, so there are a few points to keep in mind to get the best performance from your system.

- Duct bend radius:

– Radius/diameter > 1.5

• Flow area:

– Avoid area changes, sharp transitions, shape changes

• Available packaging space in the vehicle usually dictates certain designs