Accessing the Knowledge Center effectively requires a simple, one-time registration.

Testing Your Turbo System

Many problems with turbo systems can be identified before the catastrophic happens through simple system testing.

Pressurize system to test for leaks

- Clamps – Check tightness

- Couplers – Check for holes or tears

- CAC core / end tanks – Check for voids in welds

Monitoring

The turbo system in your car should be monitored to insure that every aspect is functioning properly to give you trouble-free performance.

Instrumentation used to monitor / optimize system: The most accurate way to calibrate and optimize a system is through data logging!

- Oil Pressure (Required to monitor engine operation)

2. Oil Temperature (Required to monitor engine operation)

3. Water Temperature (Required to monitor engine operation)

4. A/F Ratio (such as a wideband sensor; required to monitor engine operation)

5. Manifold Pressure

6. Turbine Inlet Pressure

7. Exhaust Gas Temperature

8. Turbo Speed Sensor

Manifold Pressure

– Calibrate actuator setting to achieve manifold pressure required to meet hp target

– Detect over-boost condition

– Detect damaged actuator diaphragm

Back Pressure

– Monitor pressure changes in turbine housing inlet

– Affect of different turbine housing A/R’s

– Increased back pressure decreases Volumetric Efficiency thus decreasing ultimate power

Pyrometer

– Monitor exhaust gas temperature (EGT) in manifold / turbine housing

– Adjust calibration based on temperature rating of turbine housing material or other exhaust components Turbo Speed

– Determine operating points on compressor map

– Determine if the current turbo is correct for the application and target hp

– Avoid turbo over-speed condition, which could damage turbo

11 Point Checklist

- Application Information – target horsepower, intended use of vehicle, etc.

2. Air filter sizing – determine size for application needs

3. Oil Supply – restrictor for ball-bearing turbo

4. Oil Drain – proper size and routing

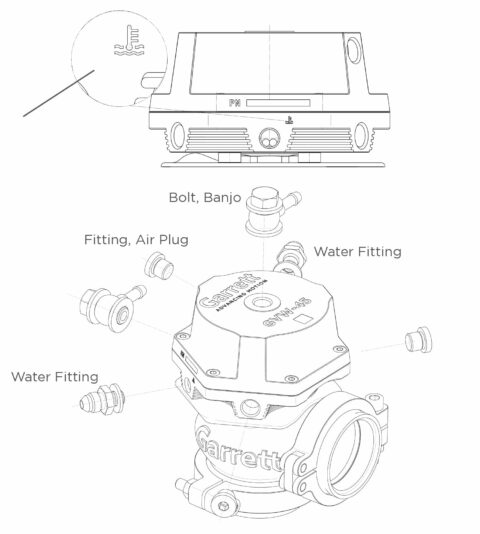

5. Water Lines – set up for greatest thermal siphon effect

6. Charge Tubing – determine diameter for application needs

7. Charge-Air-Cooler – determine core size for application needs, design manifolds for optimal flow, mount for durability

8. BOV – VTA for MAP engines and by-pass for MAF engines

9. Wastegate – connect signal line to compressor outlet, smooth transition to external wastegate

10. System Testing – pressurize system to check for leakage, periodically check clamp tightness and the condition of

couplers

11. System Monitoring – proper gauges/sensors to monitor engine for optimal performance and component durability