Accessing the Knowledge Center effectively requires a simple, one-time registration.

Performance & Reliability

How a Turbo Works - Advanced

Step up a level and explore wheel trim, turbine housing A/R and housing sizing, log style vs. equal length manifolds, compression ratio with boost, and air/fuel ratio tuning: rich vs lean. Please also see our basic and expert guides of how turbo works.

Wheel Trim

Trim is a common term used when talking about or describing turbochargers. For example, you may hear someone say “I have a GT2871R 56 Trim turbocharger”. What is ‘Trim?’ Trim is a term to express the relationship between the inducer and exducer of both turbine and compressor wheels. Learn more by downloading our guide:

Turbine housing A/R and housing sizing

When discussing engine tuning the ‘Air/Fuel Ratio’ (AFR) is one of the main topics. Proper AFR calibration is critical to performance and durability of the engine and its components. The AFR defines the ratio of the amount of air consumed by the engine compared to the amount of fuel. Learn more by downloading our guide:

Performance & Reliability

Log Style vs. Equal Length Manifolds

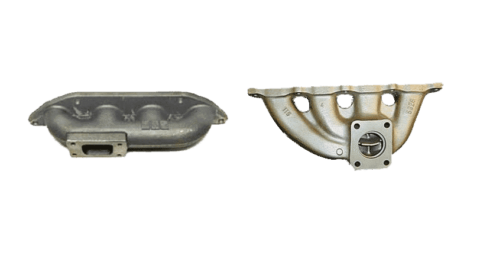

There are two different types of turbocharger manifolds; cast log style and welded tubular style

Cast manifolds

Cast manifolds are commonly found on OEM applications. Cast manifolds are generally very durable and are usually dedicated to one application. They require special tooling for the casting and machining of specific features on the manifold. Learn more by downloading our guide:

Welded tubular manifolds

Welded tubular manifolds can be custom-made for a specific application without special tooling requirements. Welded tubular manifolds are a very effective solution. One item of note is durability of this design. Properly constructed tubular manifolds can last a long time. Learn more by downloading our guide:

Compression ratio with boost

Before discussing compression ratio and boost, it is important to understand engine knock, also known as detonation. Knock is a dangerous condition caused by uncontrolled combustion of the air/fuel mixture. This abnormal combustion causes rapid spikes in cylinder pressure which can result in engine damage.

Three primary factors that influence engine knock are:

- Knock resistance characteristics (knock limit) of the engine: Since every engine is vastly different when it comes to knock resistance, there is no single answer to “how much.” Design features such as combustion chamber geometry, spark plug location, bore size and compression ratio all affect the knock characteristics of an engine.

- Ambient air conditions: For the turbocharger application, both ambient air conditions and engine inlet conditions affect maximum boost. Hot air and high cylinder pressure increases the tendency of an engine to knock. When an engine is boosted, the intake air temperature increases, thus increasing the tendency to knock. Charge air cooling (e.g. an intercooler) addresses this concern by cooling the compressed air produced by the turbocharger

- Octane rating of the fuel being used: octane is a measure of a fuel’s ability to resist knock. The octane rating for pump gas ranges from 85 to 94, while racing fuel would be well above 100. The higher the octane rating of the fuel, the more resistant to knock. Since knock can be damaging to an engine, it is important to use fuel of sufficient octane for the application. Generally speaking, the more boost run, the higher the octane requirement.

This cannot be overstated: engine calibration of fuel and spark plays an enormous role in dictating knock behavior of an engine. Learn more by downloading our guide:

Air/Fuel Ratio tuning: Rich vs Lean

When discussing engine tuning the ‘Air/Fuel Ratio’ (AFR) is one of the main topics. Proper AFR calibration is critical to performance and durability of the engine and its components. The AFR defines the ratio of the amount of air consumed by the engine compared to the amount of fuel. Learn more by downloading our guide: