Accessing the Knowledge Center effectively requires a simple, one-time registration.

Why do turbochargers fail?

A turbocharger is an air pump, which supplies air for the engine combustion process at higher pressure and density than ambient air. The turbocharger air contains a higher concentration of oxygen allowing greatly improved combustion, for more power, cleaner emissions, improved engine torque output and reduces the pumping losses within the engine offering all-round better performance.

As an integral part of the engine’s oil, fuel, air and cooling systems, any faults in these systems, can cause an incorrect turbo operation and potentially damage.

The three turbo killers

Less than 1% of turbos fail because of manufacturing defects. Most failures are caused by the three ‘turbo killers’ of oil starvation, oil contamination and foreign object damage.

More than 90% of turbocharger failures are caused oil related either by oil starvation or oil contamination. Blocked or leaking pipes or lack of priming on fitting usually causes oil starvation.

There are many types of contamination which may be carried by the engine oil into the turbo bearing system and cause damage.

There are many types of contamination which may be carried by the engine oil into the turbo bearing system and cause damage.

The most common are fine particles; usually carbon from the combustion process and if the concentration of these particles becomes too high, it acts a very effective abrasive, gradually eroding and polishing the running surfaces of the bearing and shaft, increasing the clearances and closing the oil feed holes, until the oil is no longer able to control the shaft. This is usually accompanied by a sharp increase in noise level and oil leaking past the turbine end seal causing oil to be burned and in vehicles without a particulate filter, noticeable exhaust smoke.

Other reasons, such as poor driving habits, can result in turbo failure, so you should also consider these causes:

-

- Prolonged engine idling can create a vacuum with the turbine

- Hard acceleration from cold will not give the oil time to circulate, causing oil starvation to the turbo and engine bearings.

- Hot engine shutdown can cause carbon build-up in the turbo, leading to bearing failure.

- Particularly in commercial vehicles such as on-highway trucks, revving the engine beyond its safe limit can cause the turbo to overspeed and over boost the engine (this can also happen in naturally aspirated engines as well), and to suffer oil starvation.

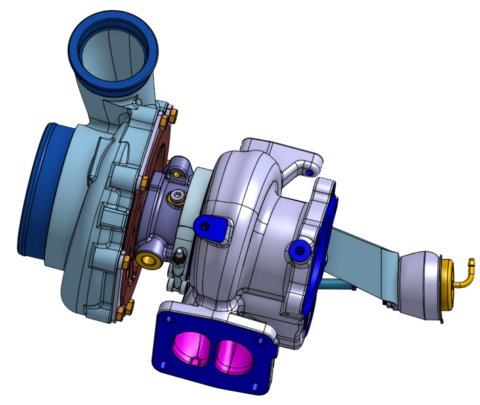

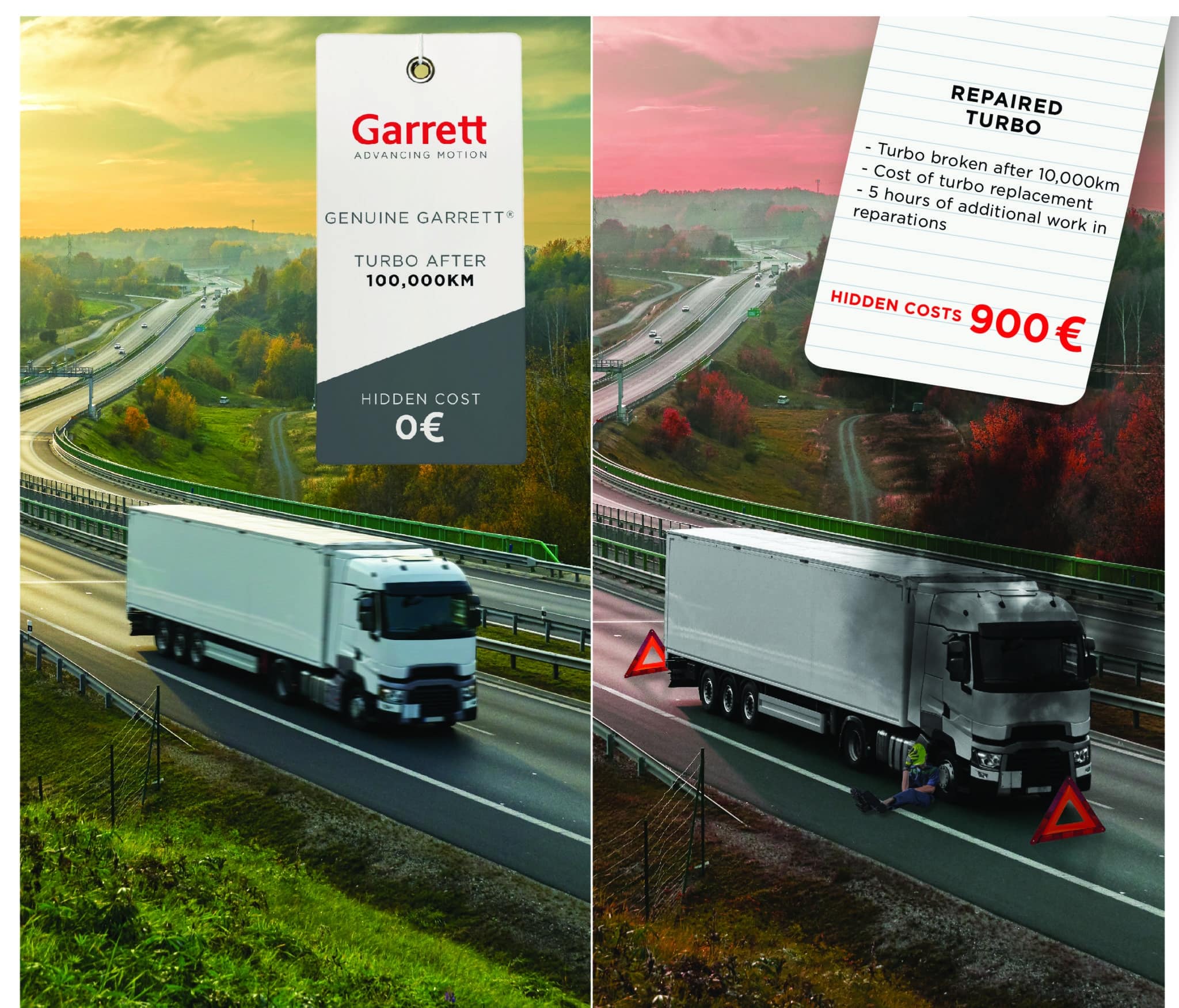

A reconditioned unit would have to use non-original parts without correct calibration, resulting in:

- Poor performance

- Premature failure

- Potential damage to the engine

- The expense of fitting another ‘new’ turbocharger

- A lost customer.

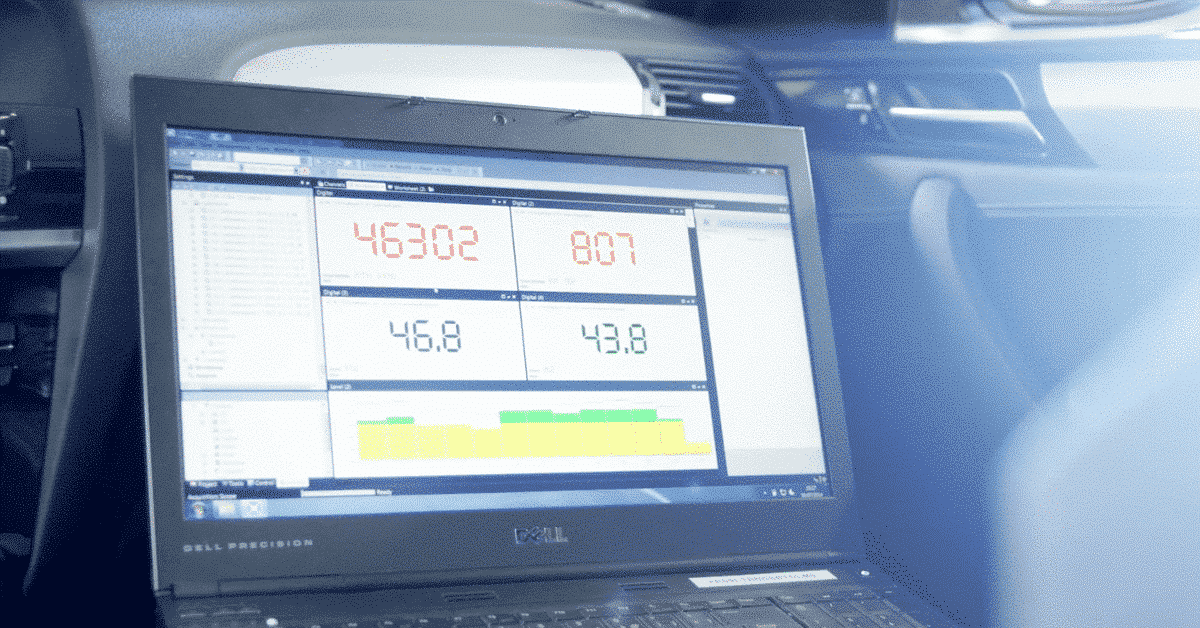

Turbocharger Troubleshooting

If you think your vehicle might have a turbo-related problem, stop before you replace because turbo damage can often be a symptom of an underlying problem rather than the cause itself. A lack of power, noisy performance or excessive smoke or oil consumption could result from a faulty fuel injection system, restricted or blocked air filters, a damaged exhaust system or a lubrication problem.

Because it’s essential to check all the systems before you replace the turbo, use the Turbocharger System Diagnostics Guide to ease your work.