On April 23rd – May 2nd 2025 in Shanghai, China, Garrett Motion will be present at AUTO SHANGHAI 2025, showcasing the company’s latest offerings in emission-reduction technology and zero-emission technology and highlighting advancements in automotive innovation.

Visit us at our booth!

Exhibition

At our booth, we will explore together Garrett’s latest highlights in zero-emission and emission-reduction vehicles, which are tailored to meet challenging emission regulations while providing optimal performance in today’s automotive market.

Come and join us in the Exhibition Area for further discussions regarding Garrett’s advancements in electric, hybrid, and ICE powertrains.

- Event Title: Auto Shanghai 2025

- Date: April 23rd -May 2nd, 2025

- Venue: Shanghai National Convention and Exhibition Center

- Organizers: Council for the Promotion of International Trade Shanghai, China Association of Automobile Manufacturers

Garrett and HanDe Partner to Electrify Heavy-Duty Trucks with Advanced E-Axle Systems

Garrett Motion Inc. and Shaanxi Hande Axle Co., Ltd. have signed a strategic agreement at the Shanghai Auto Show to co-develop and manufacture electric beam axle systems for medium and heavy-duty trucks, marking a significant milestone in commercial transport electrification.

Technologies on display

High Power Density 3-in-1 E-Axle

Garrett’s solution boosts performance by increasing power while reducing weight and size. With unique high-speed motor expertise, the E-Axle technology significantly enhances power density, contributing to the progress made in more sustainable electric mobility solutions.

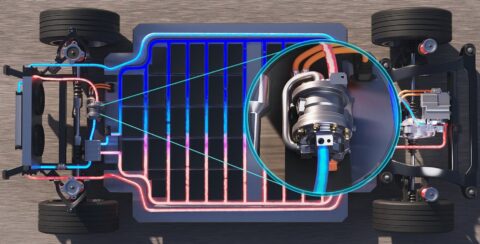

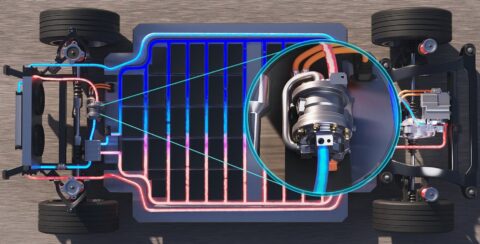

High Power E-Cooling Compressor for EV Thermal Management

Designed with a compact, oil-less architecture, the Garrett e-cooling compressor operates at incredibly high speeds, contributing to a more efficient energy management system and vehicle range increase. This reduces battery size and, consequently, vehicle weight..

Hydrogen Fuel Cell Compressor

Garrett’s solution boosts performance by increasing power while reducing weight and size. With unique high-speed motor expertise, the E-Axle technology significantly enhances power density, contributing to the progress made in more sustainable electric mobility solutions.

48V Electric Compressor for Hybrid Vehicles

Garrett electric compressors can deliver unmatched power density through superior aerodynamics and electrical design, helping automakers achieve the diesel and gasoline powertrain efficiency required to meet stringent emissions standards.

E-Turbo | A Key Technology for EU7

Garrett is pioneering E-Turbo technology to deliver superior performance, fuel economy and emissions. By integrating state-of-the-art, ultra highspeed electric motors and power electronics into it’s turbocharger product families.

Variable Geometry Turbo (VNT) for Gasoline Engines

Facing increasingly stringent emissions and efficiency standards, automakers require innovative technology solutions to stay on top of the industry. Garrett’s variable geometry turbos (VNT) use an advanced design—enhanced with all-new aerodynamics and materials—to achieve cost-effective, best-in-class performance and fuel economy.

Commercial Vehicle Turbochargers for CNG Applications

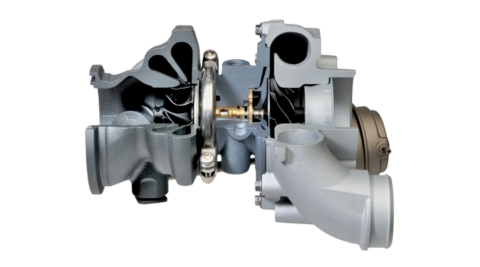

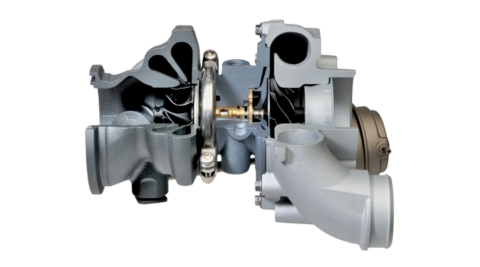

Garrett engineers have developed wastegate architectures to boost Natural gas powertrains, utilizing compressor and turbine innovations, with a particular focus on kinematic robustness as the duty cycle of wastegate actuation is several times more severe than a turbo designed for diesel. Garrett’s best-in-class twin scroll turbine design offers optimal exhaust flow separation to improve combustion, while electrification is also being introduced to enhance turbo responsiveness and control.

Wastegate Turbochargers for Gasoline Engines

Garrett’s gasoline wastegate turbos, with optimized aerodynamics and versatile turbine and compressor wheels, meet the needs of both low and high-power engines. These turbochargers, often equipped with electric-actuated bypass valves and high-temperature aerospace alloys, operate efficiently at higher temperatures.

Are you participating in Shanghai International Automobile Industry Exhibition? Connect With Us

* These fields are required.