- About Us

- Technology

- Emission Reduction Technology

- Zero Emission Vehicle Technology

Gain access to thought leadership and practical knowledge to increase your expertise in ...

Visit the Knowledge Center

How can high-speed technology reshape the way we think about electric propulsion?

Watch the Webinar

- Emission Reduction Technology

- Racing & Aftermarket

- Careers

- Grow Your Career

Jan Matulik is passionate about innovation in products and processes – and he found the perfect environment for what drives him when he joined Garrett...

Read more about Garrett Careers

Since joining Garrett as a manufacturing engineer in 2016, Mandy Zhang’s skills development across multiple roles has led to a...

Read more about Garrett Careers

As an indirect procurement specialist, Korea-based Sujin Ok thrives on being part of a global network comprising Garrett Motion...

Read more about Garrett Careers

- Grow Your Career

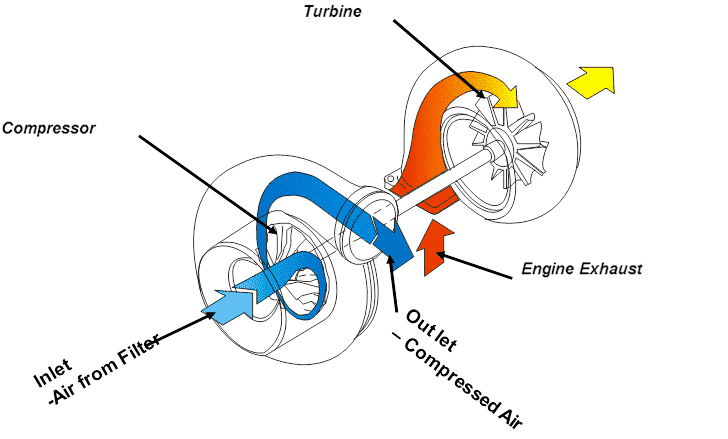

HOW DOES TURBOCHARGER WORKS ?

High temperature, high pressure exhaust gases from the engine enter the turbine housing and drive the turbine wheel. The turbine wheel is connected to the compressor wheel with a solid shaft. The rotation of the compressor wheel compresses the ambient air and forces it into the engine. This increases the amount of fuel that can be burnt, increasing the efficiency and power output of the engine.

BENEFITS OF TURBOCHARGING

Increased power output of the engine

Increased power output of the engine Engine power retained at altitude

Engine power retained at altitude Reduced engine size and weight

Reduced engine size and weight

Reduced emissions

Reduced emissions Reduced fuel consumption

Reduced fuel consumption Reduced cost of ownership

Reduced cost of ownership

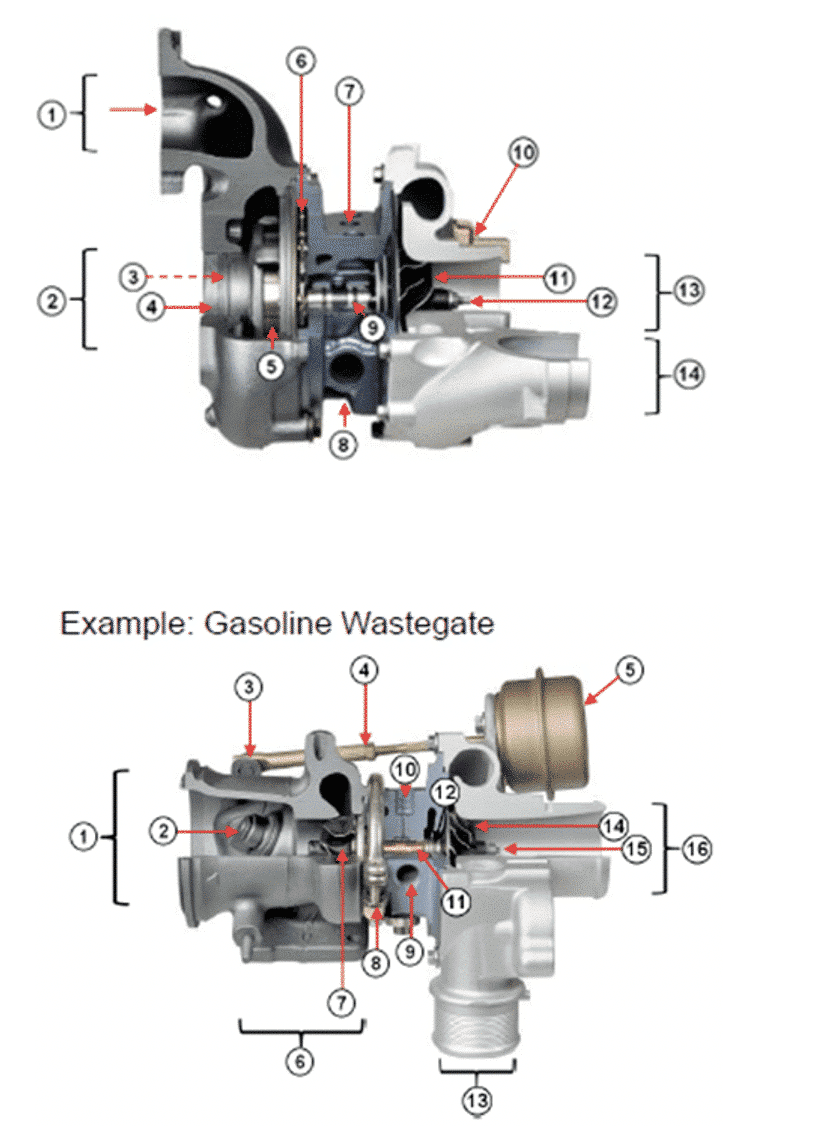

TURBOCHARGER PART DESCRIPTION

- Turbine gas inlet

- Turbine gas outlet

- Turbine wheel (hidden)

- Cartridge

- Vanes

- Unison ring

Example: Gasoline Wastegate

- Turbine gas outlet

- Wastegate valve

- Wastegate crank

- Actuator rod

- Pneumatic actuator body

- Turbine gas inlet

- Turbine wheel

- V-band

- Center housing oil outlet

- Center housing oil outlet

- Center housing oil inlet

- Bearing

- Electric actuator

- Compressor wheel

- Shaft

Gasoline Wastegate

- Center housing oil inlet

- Bearing

- Piston ring

- Compressor air outlet

- Compressor wheel

- Shaft

- Compressor air outlet

© 2025 Garrett Motion Inc.