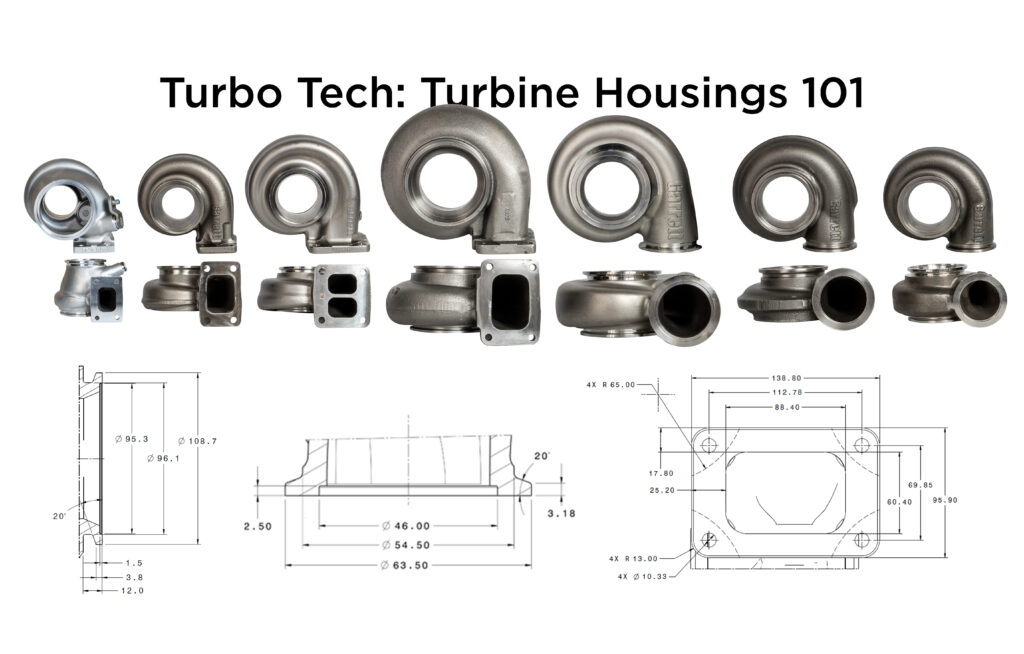

Turbo Tech: Turbine Housings 101

Turbo Tech: Turbine Housings 101

This article is your one stop guide to understanding the differences between turbocharger turbine housings, flange types and, flange specs. Have you ever asked yourself, “What’s the difference between T3, T4, T6, and V-band turbine housings”? Or maybe, “will a T25 inlet flange work on a T3 manifold”? Or, “what does T3 T4 mean?” If so this article is for you.

Let’s start with some basic principles.

Turbine housing– collects exhaust gasses from an engine and directs it through a volute (passage) which drives the shaft wheel assembly of a turbo causing it to spin. Turbine housings are also referred to as the “hot side” of the turbo because of its continuous exposure to hot exhaust gas. Turbine housings are very robust and manufactured using hi-temp materials with temperature ratings up to 1050° C.

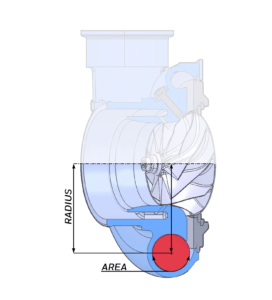

Volute– the internal passage in which the exhaust gasses travel through, from turbine housing inlet to turbine housing outlet. The passage decreases in area from inlet to outlet which speeds up the velocity of the exhaust gas flow. Volutes are offered in different sizes and measured in A/R, Area Over Radius. The larger the number, the larger the passage when referring to a specific turbine wheel size.

A/R: Area Over Radius– the inlet cross-sectional area divided by the radius from the turbo centerline to the centroid of that area. Turbine performance is greatly affected by changing the A/R of the housing. Using a smaller A/R will increase the exhaust gas velocity into the turbine wheel providing increased turbine power at lower engine speeds and resulting in quicker boost response. The smaller A/R also causes the flow to enter the wheel more tangentially, which reduces the ultimate flow capacity of the turbine wheel. This will increase exhaust back pressure and reduce the engine’s ability to breathe effectively at high RPM, adversely affecting peak engine power. Using a larger A/R will lower exhaust gas velocity, and delay boost response. The flow in a larger A/R housing enters the wheel in a more radial fashion, increasing the wheel’s effective flow capacity, resulting in lower back pressure and more power at higher engine speeds. When deciding between A/R options, be realistic with the intended vehicle use and choose the A/R to bias the performance toward the desired power band characteristic.

Twin Scroll– Turbine housing with a twin volute. This can improve boost response when used with a twin scroll exhaust manifold. Twin scroll housings are also referred to as divided housings.

Single / Open Scroll– Turbine housing with a single volute.

Turbine housing outlet– the housing opening where exhaust gas exits the turbine housing and is directed to the exhaust system of the vehicle.

Turbine housing inlet– the housing opening where exhaust gas enters the turbine housing.

Turbine housing inlet flange– Depending on the size and manufacturer of the turbo, there are several types of turbine housing inlets, all with different dimensions. Smaller turbos use smaller inlet flange types like T25, while large turbos use larger flanges like T6. Garrett engineers flow test and match the turbine inlet size with the turbocharger’s performance specs. Garrett performance turbine housings are offered in T25, T3, T4, T6, and V-Band turbine housing inlet connections.

Have you ever asked yourself, “What’s the difference between T3, T4, T6, and V-band turbine housings”? Or maybe, “will a T25 inlet flange work on a T3 manifold”? Or, “what does T3 T4 mean”? This is where we get into all of that. Let’s start with some diagrams that explain the main flange types available in most of the current Garrett performance turbo chargers. We may not cover everything, but we will cover the most popular current turbine housing configurations.

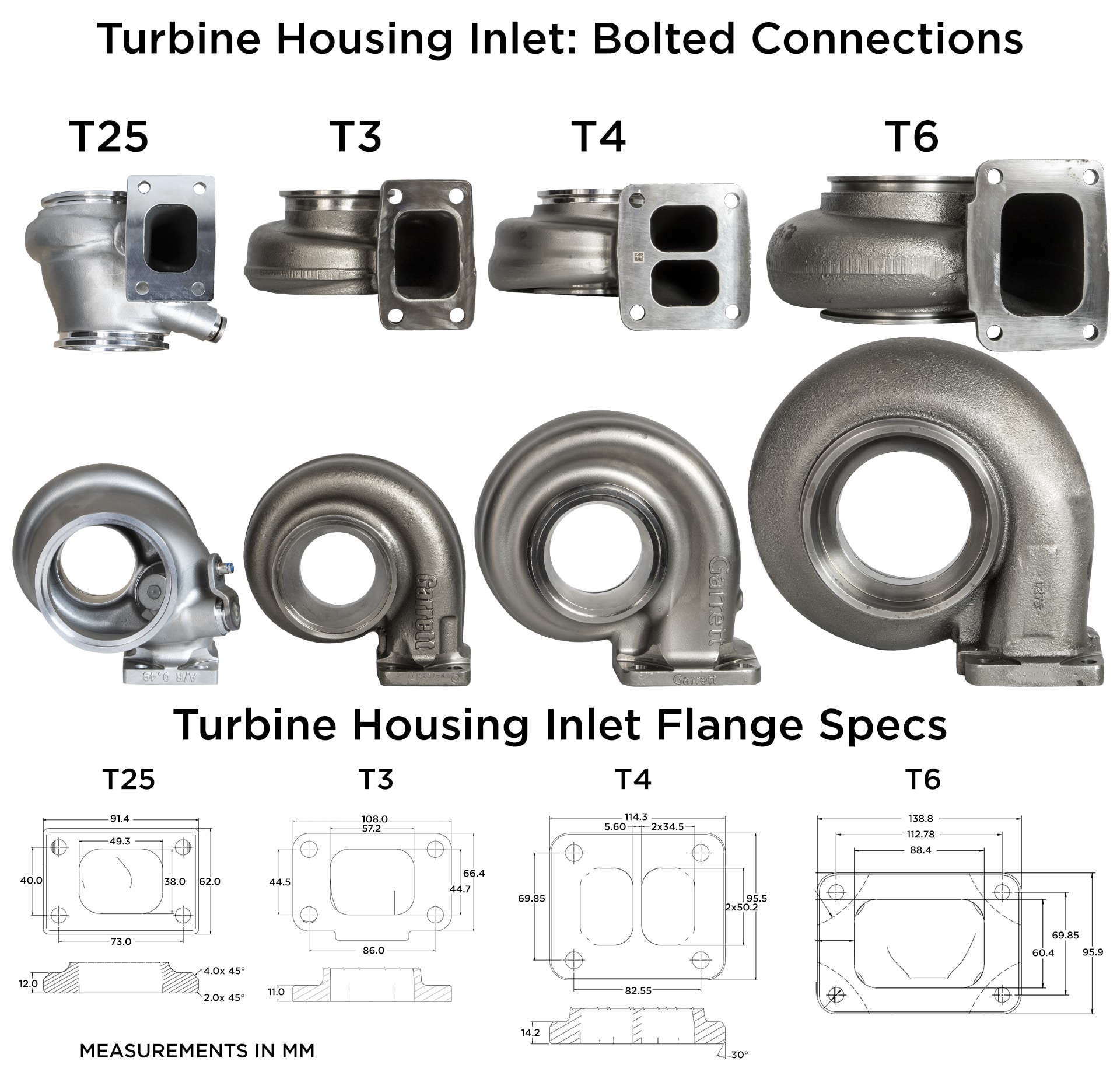

Turbine Housing Inlet: Bolted Connections

In the image above, you can see the four types of bolted turbine housing inlet flanges: T25, T3, T4, and T6. The flange specs are there for you to compare. There is a big difference in size between the T25 and the T6. One nice thing about bolted flanges is the “bolt pattern” dimensions do not change between manufacturers. A T4 flange bolt pattern is always a T4. One thing to note: the T4 diagram in the image is a T4 twin scroll turbine housing and that is why the turbine inlet has two ports while the other three are open or single scroll. Some manufacturers offer both open scroll and twin scroll turbine housings. Twin scroll turbine housings can improve turbo response when using a twin scroll manifold (a topic for another article).

Turbine housing inlet flange type is important to identify when selecting an exhaust manifold for your vehicle. You need to know what flange is on the exhaust manifold, so you can find a turbine housing and turbo that fit. Same goes when you are fabricating your own manifold, only you would need to know what flange type to buy. Garrett does not offer weld flanges but there are companies that offer them. See the list at the bottom of the article.

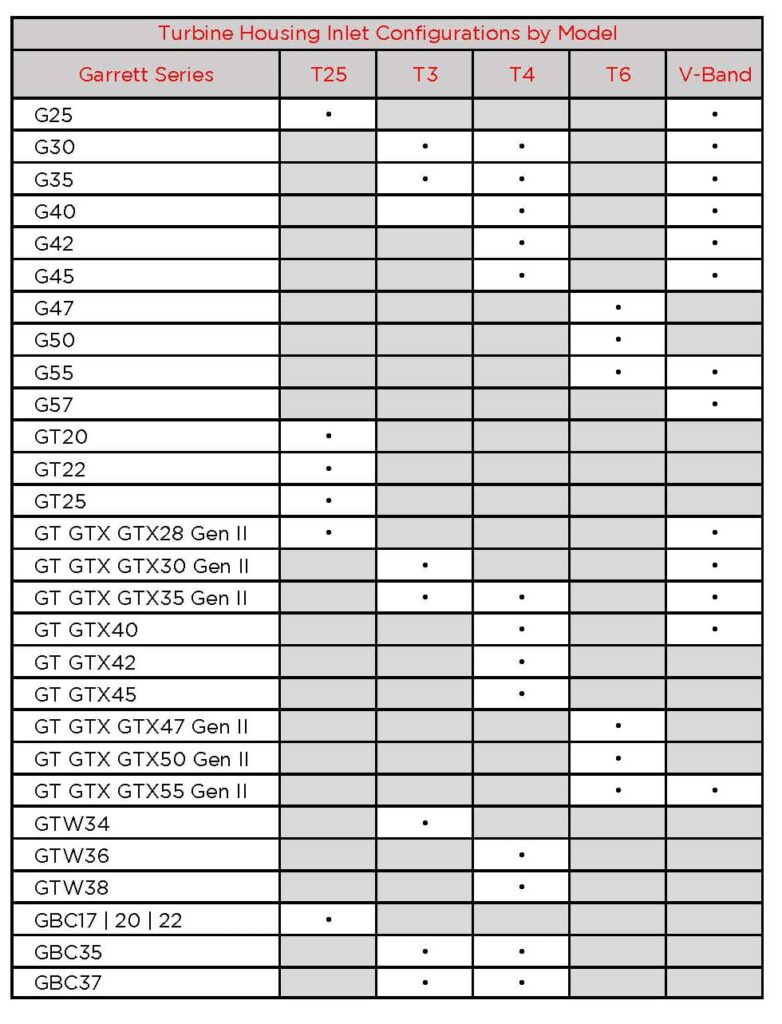

In the chart below, you can see most of the Garrett turbine housing inlet options available by series. This can be a quick reference guide to selecting the correct turbo combination for your vehicle. Remember, a turbine housing is engineered only to fit a specific turbo series. For example, G25 has T25 and V-Band turbine inlet flange options. G25 turbine housings can fit any of the G25 turbochargers (G25-550 and G25-660). GTX35 has T3, T4, and V-Band turbine inlet flange options, those part numbers can fit any of the GTX Gen II GTX and GT turbochargers because the GT GTX GTX35 GEN II frame size uses the same turbine wheel (GTX3582, GT3582, GTX3576, GT3576).

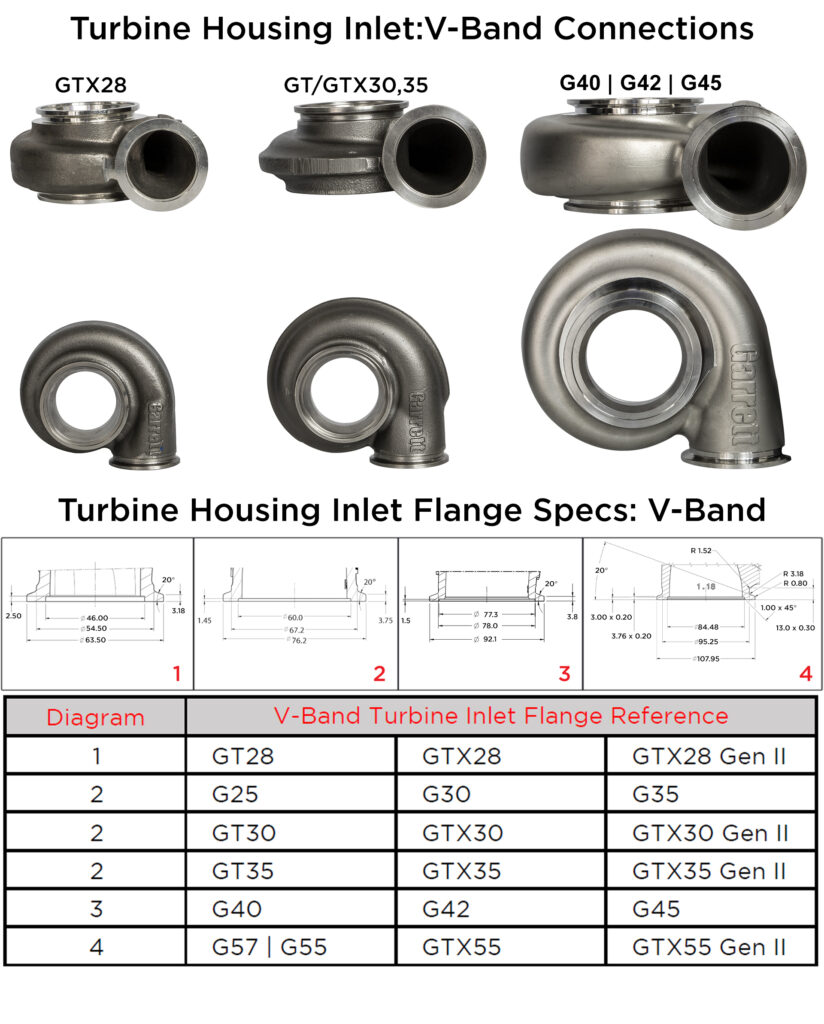

Turbine Housing Inlet: V-Band Connections

Let’s talk about something you may have noticed on the last chart. There was a column labeled V-Band. V-Band is a circular turbine housing inlet flange type that uses a clamp to make a tight connection to the exhaust manifold. V-Band inlet housings are becoming more and more popular because they have a secure connection point that is easy to attach, and they provide more flexibility to move the housing around. Garrett V-Band turbine inlet flanges are stepped to allow the weld flange / manifold flange to easily center itself.

V-band turbine inlet flanges vary in diameter depending on the size of the turbocharger, so it is important to understand the differences in the turbine housing inlet flange specs. In the diagram below, you can see all of the different V-band flange specs across the Garrett performance turbo portfolio. The image only shows three different housings but there are 4 different V-Band turbine inlet flange specs currently offered by Garrett.

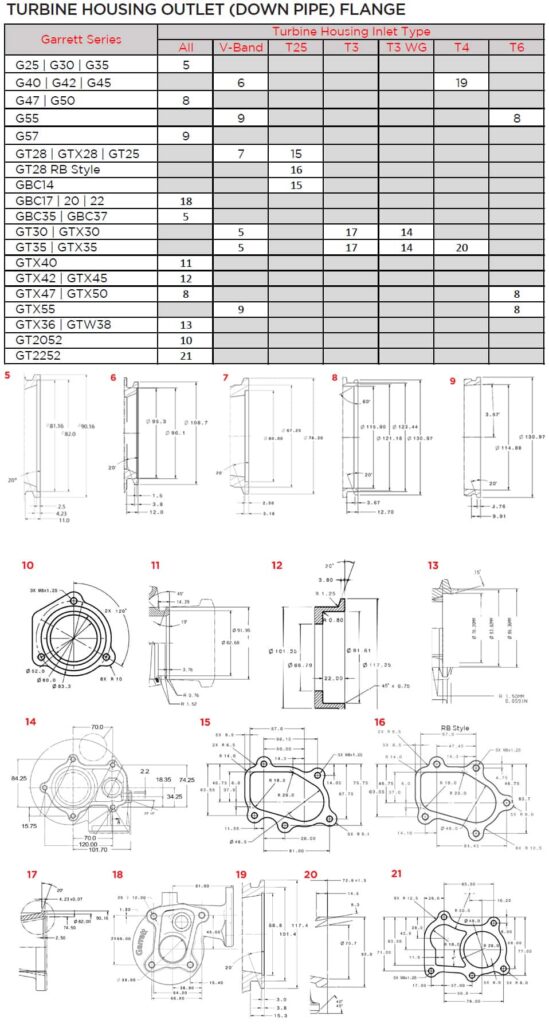

Turbine Housing Outlet: Bolted and V-Band Connections

It wouldn’t be a complete turbine housing flange guide without turbine housing outlet diagrams for all the current Garrett performance turbos. So here it is, just use the chart to identify the series and inlet of your turbocharger, then find the flange reference ID and locate the outlet flange diagram.

Where to purchase flanges for your project

Since mating flanges are not included with a turbocharger purchase, there are many companies that machine these flanges. Here’s a list of the one’s we know about.

ATP Turbo https://www.atpturbo.com/mm5/merchant.mvc?Screen=CTGY&Store_Code=tp&Category_Code=FLG

GCG Turbo

https://gcg.com.au/101.html

That’s all there is to it, your one stop flange guide for Garrett turbine housings. We hope you enjoy the article, please share and bookmark this page for future reference and we thank you for reading.