Turbocharging At Elevation

Turbocharging at Elevation

Have you ever tried to exert yourself at elevation and notice you become out of breath more quickly than at sea level? This is because the oxygen density of the air you breathe decreases as you go higher in elevation. A similar thing happens to an engine’s horsepower. As a car drives higher up a mountain road it starts to lose more and more horsepower because less and less oxygen enters the cylinder per cycle. This article will teach you more about how to turbocharge at elevation.

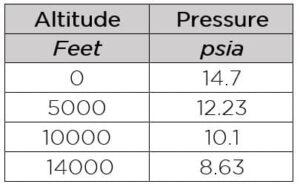

Contrary to belief, the higher you are in elevation the less atmospheric pressure you experience. That said, oxygen levels at any set volume (a breath of air, or an engine cycle) at sea level contain more oxygen then the same (breath of air, or an engine cycle) at a higher elevation. The chart below shows how pressure changes with elevation. The higher the ambient pressure (psia), the more oxygen it contains.

As a general rule, a naturally aspirated combustion engine will lose 3% of its power for every 1,000 ft of elevation gain. If you have 100 horsepower at sea level by the time you get to 5,000 feet of elevation your engine is making 85 horsepower.

- At 10,000 feet of elevation your engine will make 70 horsepower.

- At 15,000 feet of elevation your engine will make 55 horsepower.

- At 15,000 feet of elevation your engine will lose 45% of its power due to lower air density.

Benefits Of Turbochargers at Elevation

Turbocharging at elevation is an efficient way to minimize horsepower loss due to elevation and lower air density. At high elevations turbochargers compress more air into the engine cylinders making up for the lower air density allowing the engine to produce power as if it was at sea level. This extra tunability is found only in turbocharged applications.

Pikes Peak International Hill Climb is a world-famous race that takes place in Colorado Springs, CO. It’s roads close to public traffic once a year as race teams from all over the world pilot their vehicles through 156 turns up the 12.42 mile course that starts at 9,000ft elevation and ends at 14,115ft at the summit. The “race to the clouds” is what some call it.

2019 marked the 96th running of this prestigious race where 100 vehicles were accepted and qualified to race. Some racers utilize naturally aspirated engines, and others have boosted engines. With the earlier information presented, can you imagine how a turbocharged vehicle provides an advantage over non—turbocharged?

Racers using boosted engines will match their turbo for the power they want to make at the start line (9,000 ft) and as they increase in elevation the ECU will adjust boost pressure and other parameters to maintain the same power as long as the turbocharger can support the additional air volume and shaft speed.

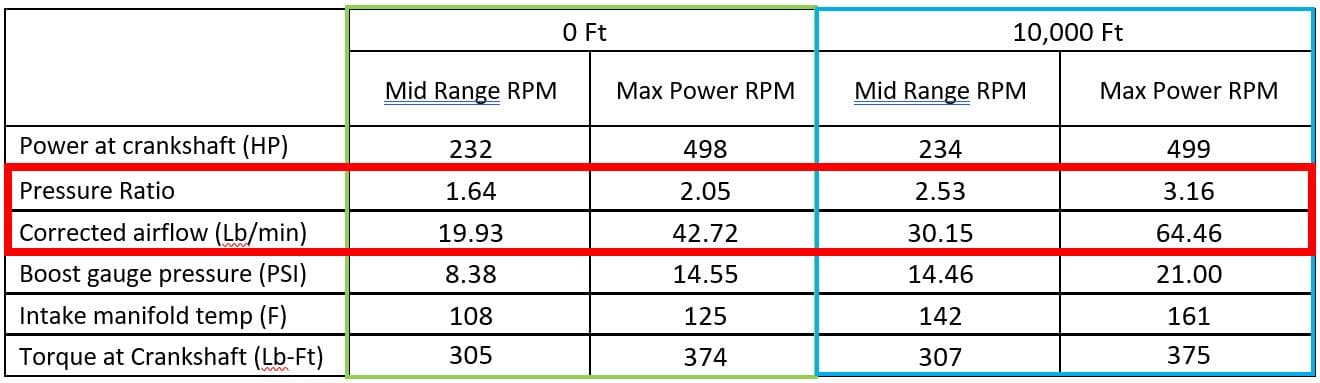

Using our free tool called Boost Adviser you can see the differences in Boost Pressure, Pressure Ratio, and Corrected Airflow needed to make the same power at different elevations. Here we compare sea level and 10,000 ft.

As an example, we entered the following parameters: 500 Target Horsepower, 3.5L Engine, Single Turbocharger, E85 Fuel, Air to Air Intercooler, 3 valves per cylinder, 4000 RPM Midrange, 7000 RPM Peak Power, 75 ° F, Elevation readings for 0 ft, and 10,000 ft

*Mid Range RPM is a measure of peak torque, and Max Power RPM is a measure of peak horsepower.

The chart above are the results of the calculations. Notice the difference in Pressure Ratio and Corrected Air Flow needed to produce the same power, with the same engine, at different altitudes. Boost pressure must also increase to compensate for the lower oxygen levels as elevation increases.

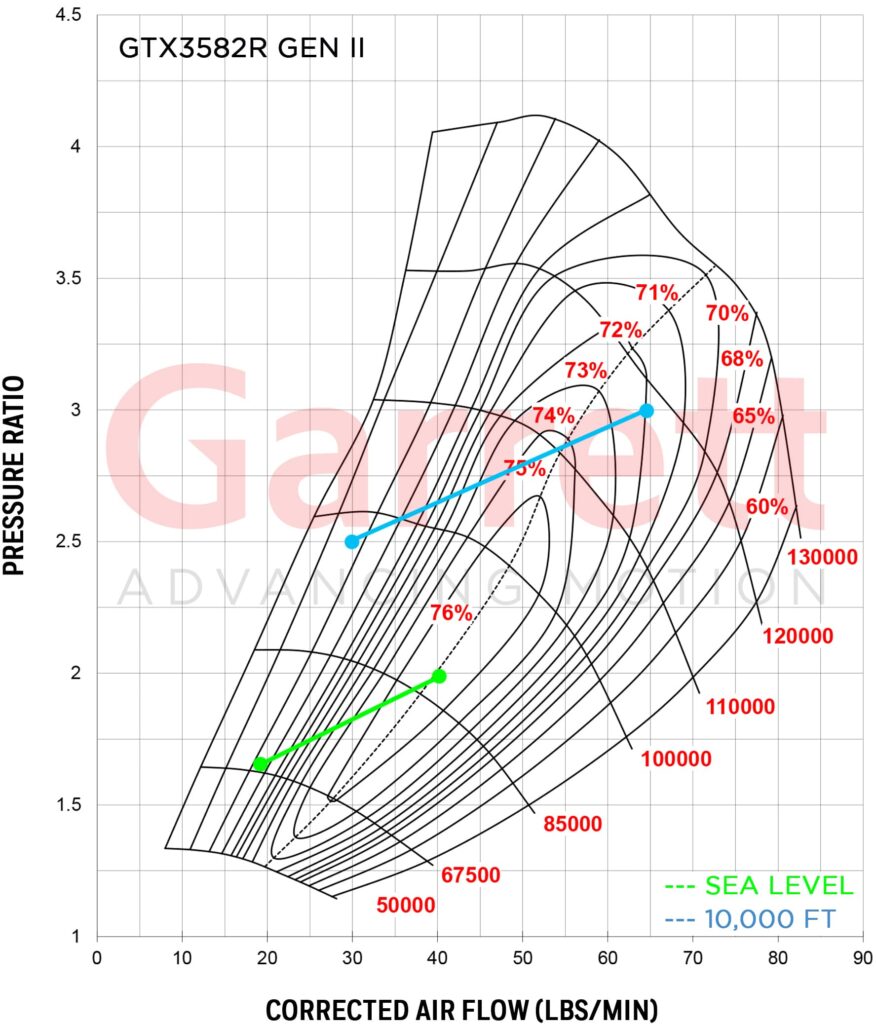

Mid range and Max power points are plotted on a GTX3582R Gen II compressor map below to help visualize the output of the compressor wheel. Using corrected flow as the X-axis and Pressure ratio as the Y-axis the colors represent different elevations. As the elevation increases the points move up and right due to the higher pressure ratios needed to produce the air flow for the Max power point.

One can conclude the GTX3582R Gen II is not the best match for a 500 horsepower race application at sealevel. But when looking at it for a 500 horsepower application at 10,000 feet of elevation you can be confident this turbo will support the air flow needed to make the target horsepower and still be within the safe operating limits of the turbo.

A speed sensor is also a good accessory to have on your turbo because it measures shaft speed information determining if the turbocharger is reaching its maximum performance, for validating the turbo match, and for insuring that it is not over-speeding, allowing you to avoid potentially damaging operating conditions. Garrett Speed Sensor Kits are compatible with datalogers to enhance engine tuning capability. The boost gauge retains the maximum wheel speed for five minutes for easy mapping.

Most vehicles do not operate at extreme elevations like at Pikes Peak, but one factor will always be constant in that turbocharged vehicles can make up for the loss in air density by compressing more air into the engine allowing horsepower to stay consistent while non-turbocharged applications will continuously loose power with elevation. To learn more about our other turbo tech topics please visit

Garrett Speed Sensor Street Kit comes with a sensor, harness, mounting hardware, and boost gauge. (Gauge not included with Pro Kit)

(Old Smokey Photos courtesy of) Toyo Tires and Larry Chen