Accessing the Knowledge Center effectively requires a simple, one-time registration.

Types of turbo in Service Replacement

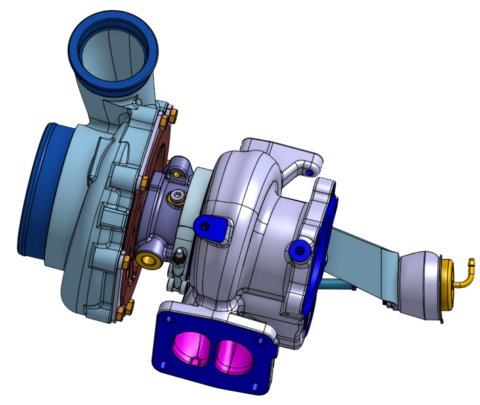

A turbocharger is an air pump, which supplies air for the engine combustion process at higher pressure and density than ambient air. The air compressed by the turbocharger supplies the engine with more oxygen, leading to greatly improved combustion. This supplies more power, cleaner emissions, improved engine torque output and reduces the pumping losses within the engine, offering all-round better performance.

The turbo can be separated into two distinct sections; the turbine stage, which is the hot end and the compressor stage which is the cold end. The turbine is driven by the waste exhaust gas from the engine and that, in turn, drives the compressor, which draws in ambient air and compresses it.

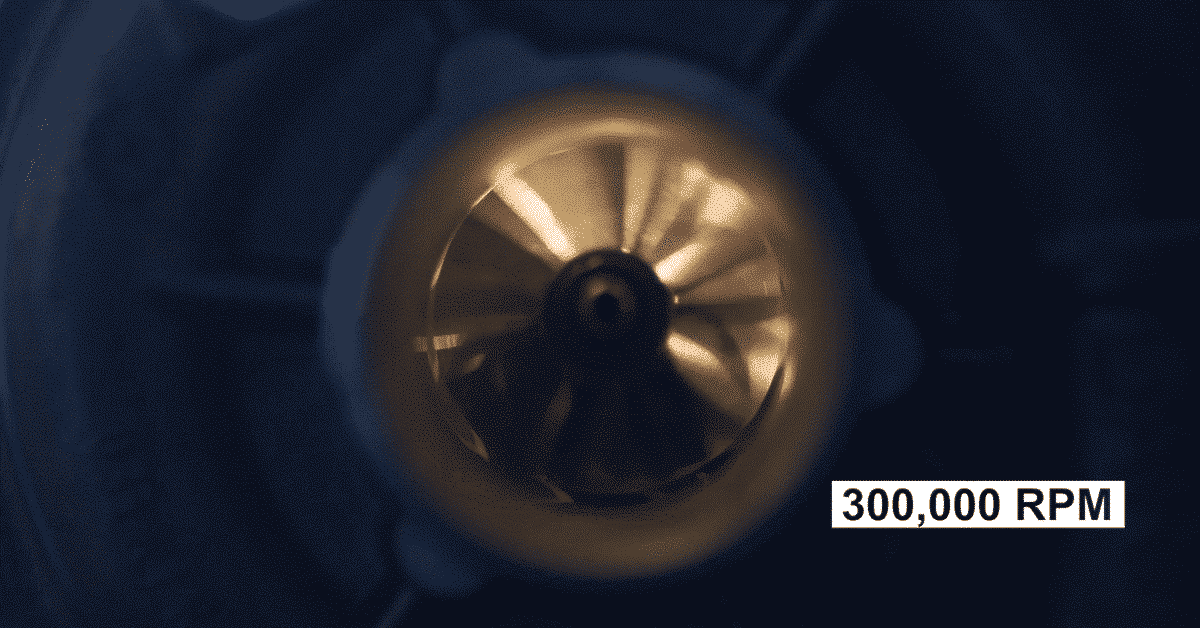

The turbocharger runs at extremely high speeds for maximum efficiency. The very largest Garrett turbo spins at up to 63,000 rpm and the smallest rotate at more than 300,000 rpm. If we consider one point on the circumference of the wheel, when operating at full speed, that point is travelling at over 1900 kilometers per hour.

Turbochargers with Wastegates

To prevent turbochargers from over-speeding and over-boosting the engine, some turbos are fitted with wastegates. At a preset level the wastegate opens and allows the exhaust gas to bypass the turbine.

Wastegates have effectively one setting. Though designed for optimum performance across a wide range of conditions, they can be responsible for turbo lag.

Wastegate turbos now represent less than 20% of the replacement turbo market.

Variable Turbine Turbochargers

Variable Turbine technology is much more complex than Wastegate technology. The turbocharger is designed to maximize boost across the whole operating range of the engine, eliminating turbo lag.

It uses complex precision variable vane or nozzle technology. These moving parts are controlled by pressure, vacuum or electronic actuators linked to the engine management system.

Due to their complexity they cannot reliably be repaired, so the manufacturers do not supply replacement parts.

If you want to learn more about turbocharger technology, join Installer Connect today, complete all the online training modules and get yourself rewarded with Garrett certificates.

Some of the topics that you will discover:

- What is a turbo and how does it work., operating conditions, exhaust gas flow, turbo & engine schematic.

- What is A/R, free-floating, turbine bypass (wastegate) and VNT.

- Inside the CHRA, internal parts & functions, lubrication & oil drainage.

- Turbo Bearing Systems and different bearing families and controlling the rotating assembly.

- The Turbocharger Oil and Gas Sealing System and dynamic, differential Pressure Sealing System, turbine End Sealing System and compressor End Sealing System.

See you there!