Turbo Lag: Causes, Effects and Solutions

In this article, we’ll be explaining what Turbo Lag is, covering the causes, effects, and how you can solve this issue by simply choosing a genuine Garrett product for

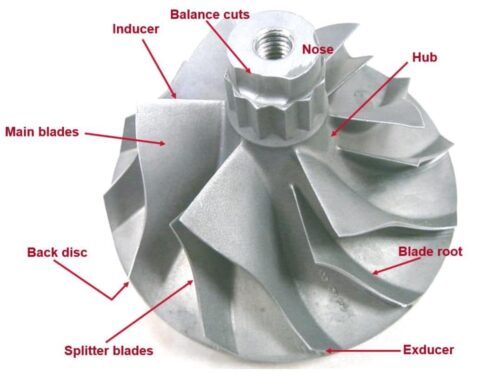

Learn moreTurbochargers play a pivotal role in boosting the efficiency and power of internal combustion engines. A core component of the turbo is the compressor wheel, which is responsible for compressing ambient air before it enters the engine’s combustion chamber.

In this article, we will dive into the anatomy of the compressor wheel, highlighting its functions and its contribution to fuel efficiency and performance.

Nose

This is the front most part of the compressor wheel, facing the incoming air. Its shape and design direct the air onto the wheel’s blades, helping to reduce turbulence and ensuring a smooth airflow.

The hub

The hub is the central part of the component and connects to the turbo shaft. In effect, it is the anchor point for the blades and is essential for transferring rotational energy from the shaft to the blades.

Blade Root

The blade root attaches the base of each blade to the hub. To enable the compressor wheel to achieve high rotational speeds, blade roots are designed to withstand significant applied force and are crucial in ensuring consistent airflow and preventing blade damage.

Exducer

The exducer is the point at which the compressed air exits the wheel on its way to the intercooler and intake manifold. In most cases it represents the longest diameter of the wheel and is essential for controlling the flow of pressurized air.

Splitter Blades

Splitter blades are smaller blades situated between the main blades of the compressor wheel. Their main role is to improve the wheel’s aerodynamic efficiency by reducing turbulence and enhancing air compression.

Back Disc

The back disc is the flat, circular portion of the component situated below the blades. It is important for wheel stability and provides a surface for the balancing cuts. A well-balanced compressor wheel is essential to minimize vibrations and ensure smooth operation.

Main Blades

The main blades are the primary components responsible for compressing incoming air. Their shape, angle and size are carefully engineered to maximize airflow and pressure increase. They play a central role in the overall efficiency of the component.

Inducer

The inducer is located just behind the nose and its role is to capture and accelerate incoming air. The design of the inducer is critical as it directly affects the wheel’s ability to draw in and compress air effectively.

Balance Cuts

Balance cuts, also known as balance holes, are precision cuts made in the back disc and the nose. These cuts are strategically placed to prevent excessive vibration and bearing wear in the turbocharger, which can lead to premature failure.

Air Compression and Increased Airflow:

The primary function of the compressor wheel is to compress incoming ambient air. As its blades spin, the wheel accelerates, resulting in increased air pressure and density (via an intercooler). This compressed air is then delivered to the engine, enhancing combustion efficiency, and optimizing power output.

Improved Engine Efficiency:

By compressing the intake air, the compressor wheel forces a greater mass of air into the engine’s combustion chamber. This helps optimize the air-to-fuel ratio, leading to more complete combustion, increased engine efficiency and better fuel economy.

Enhanced Power Output:

Compressed air in the combustion process allows the engine to burn fuel more efficiently, leading to a significant boost in power output. This improved power-to-weight ratio enables smaller engines to perform better.

Better Throttle Response:

A turbocharger equipped with an efficient compressor wheel enhances throttle response by reducing turbo lag (the delay between the driver pressing the accelerator and the turbo delivering increased power). A well-designed compressor wheel minimizes this lag, providing a more responsive and agile driving experience.

A damaged compressor wheel will significantly impact turbo performance. Here are some signs and symptoms to look out for:

Loud whistling or Screeching noises

A damaged or broken compressor wheel may produce unusual high-pitched whistling or screeching sounds, especially during acceleration or when the turbocharger is spooling.

Reduced Boost Pressure

A damaged compressor wheel can lead to reduced boost pressure, causing a decrease in overall engine performance and power. This can be particularly noticeable during acceleration or under heavy load.

Poor engine performance

A damaged compressor wheel will result in a degraded engine performance, with decreased power and sluggish acceleration due to insufficient compressed air being delivered to the engine.

Excessive Smoke from Exhaust

A damaged compressor wheel will become unbalanced, causing excessive vibration of the rotating assembly (CW & shaft wheel assembly). This can result in premature wear of bearing & sealing systems and often lead to oil leaking into the compressor / turbine housing, followed by a catastrophic turbo failure.

If you are looking to diagnose your turbocharger, use our tool.

In summary, the compressor wheel is a complex component of a turbocharger, and each of its elements plays a crucial role in the performance and reliability of the turbocharging system. Engineers carefully design compressor wheel components to deliver the mass and density of air need to provide the desired engine boost and powertrain efficiency. Understanding the anatomy of the compressor wheel is essential for appreciating the intricacies of turbocharged engines and their role in modern automotive technology.