Accessing the Knowledge Center effectively requires a simple, one-time registration.

Types of turbo: say hello to turbocharging

Around the world, around the clock, Garrett Motion turbochargers are boosting millions of cars, vans and trucks. It’s a technology synonymous with fuel efficiency, performance and emissions reduction and it’s an essential component of powertrain design, whether for gasoline, diesel or hybrid engines.

There are two distinct stages involved in turbocharging. There’s a turbine stage, which harnesses energy from waste exhaust gases. And there’s a compressor stage, driven by the turbine, which draws in ambient air, compresses it and forces it into the combustion process.

Why is this important? Because forcing higher pressure oxygen into the combustion process creates more efficient burning of fuel and improved torque. The result is more power, cleaner emissions, enhanced fuel economy and reduced the pumping losses, offering all-around better performance.

Turbos are extremely complex machines running at very high speeds – up to 300,000 rpm – for maximum efficiency. When operating at full speed, any single point on the circumference of the wheel is traveling at over 1900 kilometers per hour.

Garrett’s leadership in turbo design creates significant value for car manufacturers and owners – and also for the garages and mechanics involved in explaining turbo replacement cost and complexity to their customers.

1. Turbo Line-up

Each Garrett turbo is perfectly matched to a specific engine range – and there’s a model for just about every mainstream vehicle make and model. In fact, there are about 8,000 OE-grade service replacement models in the Garrett Aftermarket line-up, covering both diesel and gasoline powertrains.

In service replacement, demand is mostly for Classic or single turbochargers (rather than two-stage models). As previously mentioned, these come in lots of different sizes and specifications, with larger turbos producing more power and smaller turbos reaching full pressure faster.

Where the turbo is located in the engine bay will depend on a number of factors, such as engine design, but generally they will be packaged as close to the exhaust manifold as possible.

One thing that should always be remembered by garages and mechanics is that Garrett turbos are guaranteed to deliver the exact same quality and performance as the original part. Beware poor quality copies that can cause significant engine damage.

2. Wastegate Turbos

Wastegate technology is used to prevent turbochargers from over-speeding and over-boosting the engine. These turbos are simple in design and architecture but are very effective in controlling boost pressure by using an actuator to open a valve that allows exhaust gas to bypass the turbine.

This is a established technology that can be found on multiple engine platforms. These turbos are proven to help to improve engine performance and today account for around 20% of the turbo replacement market.

Wastegates effectively have one setting, and although extremely reliable they are not as responsive (turbo lag) as other turbo technologies in optimizing performance across the entire engine map.

3. Variable Geometry Turbine Turbos

Variable geometry turbine technology is much more complex than wastegate technology. Here, the turbocharger is designed to maximize boost across the entire engine operating range, significantly improving responsiveness and driveability.

This architecture uses complex precision variable vane technology controlled by pressure, vacuum, or electronic actuators linked to the engine management system.

Due to their inherent complexity, these turbos cannot reliably be repaired, so manufacturers do not supply replacement components.

4. Variable Nozzle Turbine | VNT™

Variable Nozzle Turbine (VNT™) is a groundbreaking technology developed by Garrett that has helped transform the ability of automakers to optimize performance while helping improve fuel efficiency and reduce engine-out emissions. In VNT™ turbos, a row of vanes moves to match the exact boost requirements of the engine, contributing to higher torque levels, better acceleration through improved transient response and cleaner combustion.

VNT™ technology comes in a mono setup and while the majority of VNT applications that will be seen in service replacements are for diesel engines in the 1.4L to 2.0L range, the architecture is also heavily specified in the premium 3.0L V6 diesel segment.

How Garrett VNT Concept works?

Garrett Variable Geometry Turbo (VNT™) is a key variable geometry turbo technology for auto manufacturers as they seek to enhance light vehicle driveability, improve fuel efficiency and reduce emissions.

A VNT Turbo is meant to improve the performance and efficiency of an engine. A standard turbocharger for example consists of a turbine and a compressor, which are linked by a shaft. The turbine is driven by exhaust gases from the engine, which causes the compressor to spin and compress air, which then goes to the engine.

A VNT, on the other hand, uses a turbine with adjustable blades that can shift the angle in response to the changes in exhaust gas flow. This process allows the turbo to operate more efficiently at different engine speeds and loads, providing better performance and fuel economy. A technology like this makes VNT a popular choice for many modern vehicles, especially for high performance or efficiency.

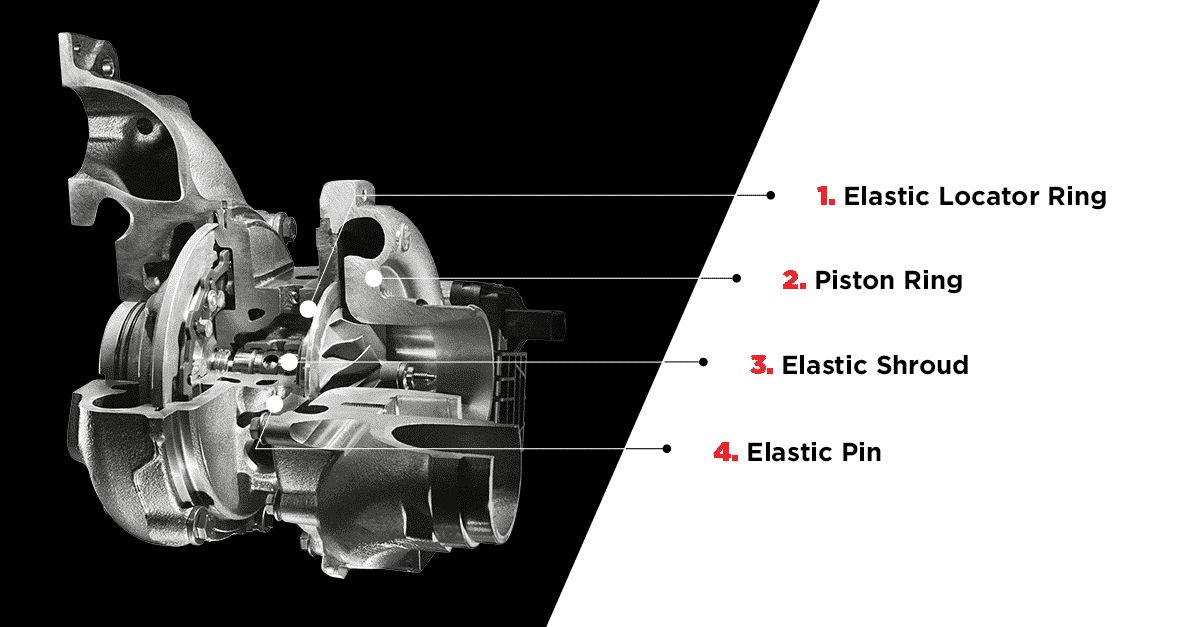

- 4 Elastic Parts are holding VNT Cartridge, fully decoupled from Turbine Housing (VNT cartridge not sensitive to turbine housing deformation & heat transfer):

- High temperature capability (Free thermal expansion with Vane Clearance stability)

- High wear resistance (Vibration & Cycling not causing wear as no clearance)

- High robustness (Clearances independent from Turbine Housing design)

Such is the success of this innovation that today there are more than 50 million VNT™ turbos in operation around the world.

VNT™ Insights:

- In a VNT™ turbo, the turbine vanes move to vary the flow of exhaust gas, providing a constantly variable range of A/R (Area over Radius). This offers improved performance over a wider engine operating range;

- The movement of the vanes is controlled by an actuator connected to an external crank assembly. This crank connects via a short shaft to the internal control arm and transfers movement to a unison ring, which controls the movement of all the vanes using their vane arms;

- On a VNT™ turbo, the vane position is constantly and rapidly changing in response to signals from the vehicle ECU to comply not only with the driver’s commands, but also with the many inputs controlling combustion efficiency and exhaust emissions;

- Full carpark coverage going as far as the Marine industry, the VNT technology is part of the portfolio of many automotive players such as: BMW, Mercedes Benz, Ford, Audi, and many more;

- HP range from 100-500. A normal car could have between 150-200 horsepower, of course, the range changes with the performance that we want to achieve and the type of care that we have.

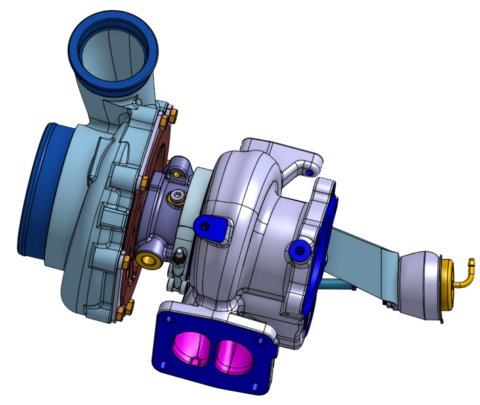

5. Two Stage Turbos

With various models, Two Stage turbo set-ups are typically chosen by auto manufacturers either to deliver engine downsizing auto manufacturers typically choose two-stage turbo set-ups to deliver engine downsizing or to uprate performance, typically for diesel engines in the 1.6L to 3.0L range.

In a Two Stage Serial system, a small high-pressure turbo works together with a larger low-pressure turbo, with the gas flow between the turbos controlled using by-pass valves linked to engine speed.

At low-speed – up to about 1500rpm – the two turbos work in full serial mode, with the compressor and turbine by-pass valves closed, providing a rapid ramp-up of boost pressure. Beyond 1500rpm, the turbos continue to work together until a full transition to the low-pressure turbo takes place, usually around 2,800rpm.

Mainly with diesel applications, types of turbos such as Two Stage have a home on the biggest automotive manufacturers, especially high end producers:

- Bentley;

- Porsche;

- Jaguar;

- BMW (main focus on M series).

Want to know more?

- To boost your turbo knowledge to expert level or to learn more about turbocharger basics, why not join Garrett’s Installer Connect and work through our online training modules. There are four modules and four Garrett certificates as reward for pursuing one turbo passion.

By joining, you’ll discover:

- How a turbo works, including insights into operating conditions and exhaust gas flow and examples of turbo and engine schematics.

- The difference between free-floating, turbine bypass (wastegate), variable geometry and two-stage.

- The turbo’s key elements, including the CHRA, internal parts & functions, lubrication & oil drainage systems.

- The role of bearing systems and how different bearing families help control the rotating assembly.

- The critical roles of turbocharger oil and gas sealing systems, including dynamic differential pressure sealing, turbine end sealing, and compressor end sealing.