Garrett Performance Intercoolers and Intercooler Cores

Garrett performance intercoolers are engineered with meticulous engineering standards to deliver thermal stability for high-boost performance systems. We design and manufacture complete vehicle-specific intercoolers and bar-and-plate intercooler cores for custom builds.

Engineered as Part of the Complete Charge Air System

Intercooler efficiency directly affects turbocharger workload, boost response, and overall system durability. Garrett designs intercoolers with a system-level approach balancing heat extraction, airflow velocity, and controlled pressure drop to ensure repeatable performance under sustained load.

Because we engineer turbochargers and charge air systems together, Garrett intercoolers are designed to operate in balance with high-performance turbo platforms rather than as isolated components.

- Balanced heat rejection and airflow efficiency

- Optimized internal fin density strategy

- Controlled pressure drop management

- Designed for sustained high-boost environments

Built for Performance. Designed for Builders.

Garrett intercoolers are engineered to deliver high thermal efficiency, structural durability, and airflow balance under sustained boost. Whether upgrading a popular turbocharged vehicle or fabricating a custom high-horsepower build, our intercooler solutions are designed to meet demanding performance standards.

From direct-fit vehicle-specific upgrades to a comprehensive range of bar-and-plate intercooler cores, Garrett supports end users, dealers, kit makers, and fabricators with scalable cooling solutions.

- Vehicle-specific OEM-fit performance intercoolers

- Air-to-Air Horizontal Flow Intercooler Cores

- Air-to-Air Vertical Flow Intercooler Cores

- Air-to-Liquid Intercooler Cores

- Horsepower coverage from 300 to 1,275+ HP

- Bar-and-plate construction

Inside Garrett Intercooler Core Engineering

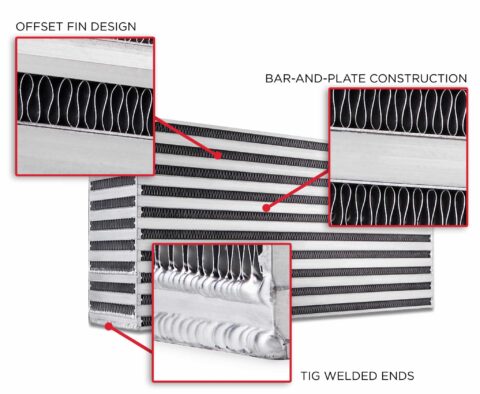

Garrett bar-and-plate intercooler cores utilize optimized internal fin density and flow passages to maximize heat rejection while maintaining controlled pressure drop.

Fin density is carefully selected based on flow path balancing surface area for thermal transfer with airflow efficiency to support repeatable performance under sustained boost conditions.

- Bar-and-Plate Construction

- Offset Fin Design

- Hot & Cold Flow Optimization

- Balanced Pressure Drop Management

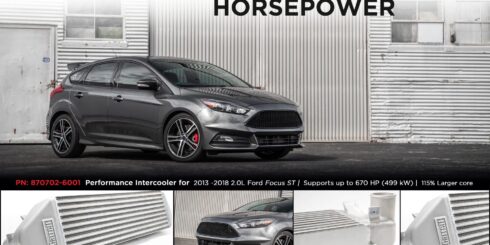

Vehicle Specific Performance Intercoolers

Garrett vehicle specific performance intercoolers are engineered as direct fit upgrades for popular turbocharged platforms. Designed to increase thermal capacity while maintaining OEM style integration, these intercoolers deliver improved charge air cooling and greater consistency under sustained boost conditions. Each application is developed using bar and plate construction and optimized internal fin architecture, balancing heat rejection and airflow efficiency while controlling pressure drop.

Direct fit installation

Increased thermal capacity

Reduced heat soak

Built for sustained boost

| Part Number | Application | Horsepower* |

|---|---|---|

| 857564-6001 | 2015+ Mustang 2.3L EcoBoost |

Up to 600 |

| 870702-6001 | 2015+ 3.5L | 2.7L Ford F 150 C.A.R.B Certified |

Up to 750 |

| 880736-6001 | 2013 to 2018 2.0L Ford Focus ST |

Up to 670 |

| 891185-6001 | 2015+ Subaru WRX 2.0L |

Up to 530 |

| 881649-6001 | 2011 to 2021 Ford Ranger | Everest | Mazda BT50 |

Up to 499 kW |

| 888883-6002 | 2015+ BMW M3 and M4 F80 F82 F83 |

Up to 980 |

| 893516-6001 | 2016+ Honda Civic 1.5L T Si |

Up to 660 |

Installation instructions are available on each individual product page.*Horsepower ratings shown for typical operating conditions. Maximum horsepower potential may exceed listed values depending on setup and calibration.

Back to top

Air to Air Intercooler Cores

Garrett Air to Air intercooler cores support aftermarket fabrication projects that require high thermal efficiency, controlled pressure drop, and durable construction under sustained boost. Select core size based on packaging constraints and horsepower targets.

Air-To-Liquid Intercooler Cores

A full range of bar and plate intercooler cores that are manufactured by Garrett technicians. Our bar and plate intercooler cores are proven to reduce intake temperatures through advanced fin density and offset composition.

| Part Number | Model | Supported Horsepower | Length/Hot Flow | Height/No Flow | Width/Cold Flow | |||

|---|---|---|---|---|---|---|---|---|

| (in) | (mm) | (in) | (mm) | (in) | (mm) | |||

| 717874-6009 | Air / Liquid | 500 | 3.8 | 97 | 3.7 | 95 | 9.8 | 249 |

| 717874-6008 | Air / Liquid | 750 | 3.8 | 97 | 3.7 | 95 | 11.7 | 297 |

| 873213-6002 | Air / Liquid | 980 | 7.2 | 183 | 3.6 | 91 | 9.8 | 249 |

| 734408-6005 | Air / Liquid | 1000 | 4.8 | 122 | 4.5 | 114 | 11.9 | 302 |

* Horsepower rating shown for normal operating conditions, Maximum horsepower potential will be higher than the listed values.

Turbochargers Intercoolers and Intercooler Cores

Utilizing advanced Aerospace technology, Garrett intercoolers offer superior fatigue protection for the high boost pressures and temperatures of today’s extreme engines. With over 75 years of charge air cooler experience, Garrett remains ahead of the industry in intercooler design and function making it the number one choice for some of the premier names in the performance car industry – Roush, Saleen, Mercedes-Benz AMG, Ford SVT, GM, and McLaren have all turned to Garrett to intercool their hottest models.

A full range of bar and plate intercooler cores that are manufactured by Garrett technicians. Our bar and plate intercooler cores are proven to reduce intake temperatures through advanced fin density and offset composition. From air-to-air cores sized for sport compact cars to air-to-liquid cores capable of supporting 1000+ hp, find the perfect fit for every project, at the perfect price with Garrett.

Vehicle specific intercoolers Selecting the right intercooler core Air-to-air cores Air-to-liquid cores Intercooler Technology

Selecting The Right Intercooler

We manufacture a wide range of air to air intercooler cores rated from 310 horsepower applications up to 1260 horsepower applications. Each core is rated for a specific horsepower, making it easy to match your desired power target to the core. In general, use the largest core that will fit within the packaging constraints of the application.

Learn More About Thermal Tech

Performance Intercoolers

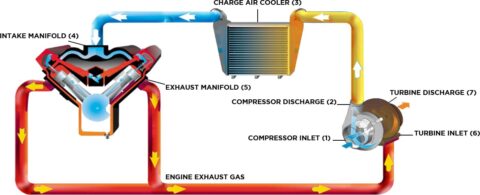

Garrett performance intercoolers and intercooler cores work together with the turbocharger as part of the total induction system. When air is compressed in the turbocharger it gains a lot of heat. Hot air is less dense and therefore is not able to produce as much energy because less can be fed into the engines cylinders. The job of the intercooler is to remove heat from the charge air making it more dense. The denser charge equals more air and fuel reaching the engine and that translates to more horsepower.

Intercooler Construction

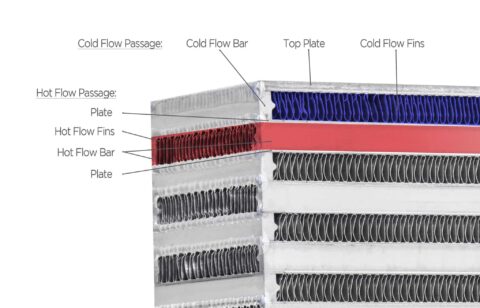

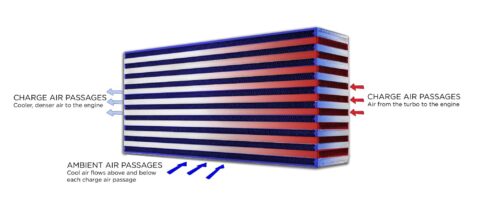

Garrett intercooler cores are bar and plate horizontal flow design. Charge air from the turbo flows within enclosed passages in one direction, with separate cooling passages flowing cooler ambient air in a perpendicular cross-flow pattern to the charge air. In bar and plate designs the passages consist of plates on top and bottom with fins in between. The passages are enclosed by bars on either side depending on if it is a charge air passage or an ambient air/cooling passage. Passages are stacked alternately until the desired stack height is reached. On the sides of the stacked cores, added to the final passage is a side plate of thicker material to provide structural integrity, protect the more delicate fins, and provide a surface for welding on end tanks if desired.

Heat Transfer

How does the intercooler remove heat from the charge air? There are three types of heat transfer modes, but the bar and plate intercooler relies on Conduction and Convection to extract heat from the charge air. Conduction is the transfer of heat to materials that have direct contact with each other. Convection is the transfer of heat from one place to another by movement of air. As you can see in the image below, the bars, plates, and fins alternate direction and flow and all play a part in extracting heat from the charge air. The charge air fins transfer heat from the charge air to the plates and the ambient air fins transfer the the heat from the plates and the ambient air cools the fins. The process repeats as long the car is moving or until the core gets heat soaked.

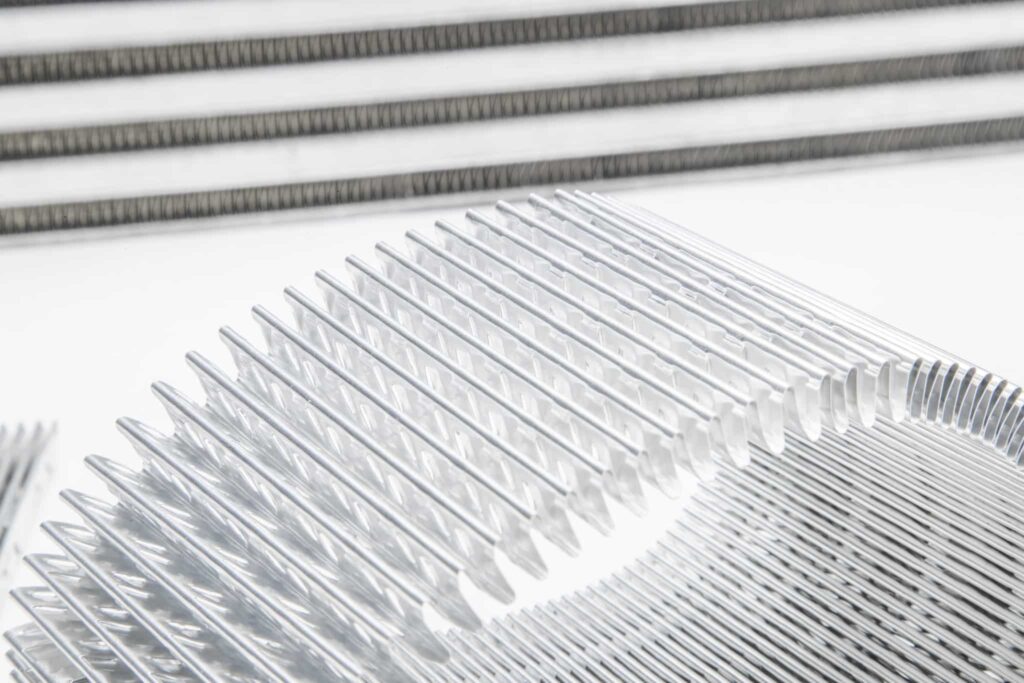

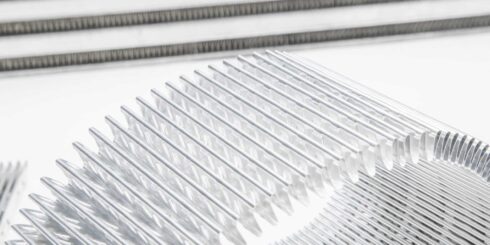

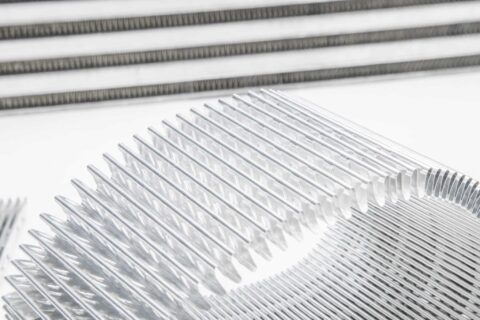

Fin Density

Fin density is measured in FPI or fins per inch. Each fin surface counts as one fin meaning there are two fins per wave. Fin stacks start off as flat sheets of aluminum that are fed through a special machine where they are bent to the desired FPI per row height and length. Garrett manufacturers around 20 different air-to-air and air-to-liquid intercooler cores supporting a range of horsepower from 310 up to 1260. Each of those cores are different in length, width, and height to meet the needs of different performance enthusiasts.

Garrett Intercooler cores utilize a combination of fin density depending on the flow path of the core. For example, the cold flow path or the front of the intercooler commonly has a higher density fin count to allow for better thermal performance and cooling. Core width/ cold flow can range from 3 – 5 inches so higher fin density is critical with the short span the ambient air travels across to cool the charge air passages. Additionally, the cold air passages are not sealed or pressurized like the charge air passages, so your ambient air flows through, cools the hot passages and evacuates into the engine compartment.

Hot flow passages have a longer run spanning from 11-28 inches in some intercooler cores. The hot flow path is a series of sealed chambers with fins spanning the entire length. There is a lot of surface area for heat transfer to take place and for that reason, the hot chambers have a lower fin density. This also helps reduce pressure drop as the charge air travels from one side to the other.

Pressure Drop

Pressure drop is the difference in pressure between two points caused by flow resistance. An example of pressure drop is when the air pressure leaving the intercooler is less than the pressure that went in. You may never actually see this happening because your turbo will work harder (spin faster) to deliver the correct PSI to the engine. The faster a turbo spins the hotter the air is so it’s critical to use an intercooler that has a good balance of fin density so you don’t overwork the turbo.

Think about driving down the road with your hand out of the window and your palm facing forward. Your hand is interrupting the flow of the air and it must find a way around your hand to pass. Now imagine you and 10 friends in a limousine with your hands out of the window one after another. The last person in line will not feel the same flow as the first person because of pressure drop.