The Quiet Revolution in HVAC: Why Oil-Free Centrifugal Compressors Are Reshaping the Industry

The HVAC industry is undergoing a transformation. Pressured by climate goals, urban expansion, and the rise of data-driven infrastructure, manufacturers and system designers are rethinking the fundamentals. Efficiency is no longer a bonus: it’s a baseline. Reliability is expected. And sustainability is non-negotiable.

At the center of this shift is a technology that’s quietly rewriting the rules: the oil-free centrifugal compressor using foil bearings.

A Simpler Machine for a Smarter World

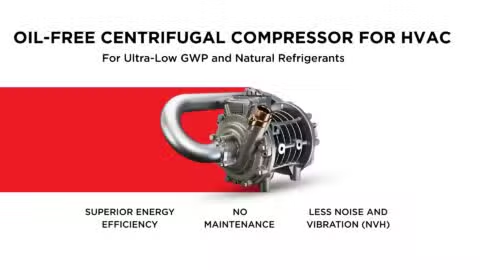

Traditional compressors rely on oil for lubrication and sealing. That means pipes, pumps, filters, and reservoirs, all of which add complexity, consume space, and introduce points of failure. Garrett’s oil-free centrifugal compressors, supported by foil bearing technology, eliminate these components entirely. The result is a frictionless, cleaner architecture that’s easier to install, simpler to maintain, and more reliable over time.

Fewer parts mean fewer problems. And in HVAC, where uptime is critical and access is often limited, think tight rooftop units, battery storage systems, or remote data centers, that simplicity translates directly into cost savings and operational peace of mind.

Safety in the Age of Low-GWP Refrigerants

As the industry moves toward low global warming potential (GWP) and natural refrigerants, new challenges emerge. Many of these refrigerants are mildly flammable, and when mixed with oil, the risks increase. Oil-free compressors remove oil from the system entirely, reducing the risk of ignition and helping OEMs and building operators meet evolving safety and sustainability standards.

This is especially important in high-stakes environments. Rooftop cooling systems for residential and office buildings must meet strict safety codes. Data centers, where even a momentary outage can cost millions, demand thermal management solutions that are both robust and risk-averse. Garrett’s oil-free design delivers both.

Quieter, Cleaner, Longer-Lasting

Noise and vibration aren’t just nuisances, they’re symptoms of inefficiency. They contribute to refrigerant leaks, shorten system life, and disrupt comfort in residential areas. Garrett’s oil-free centrifugal compressors operate with significantly lower vibration and up to 10 dBA noise reduction, making them ideal for urban installs and acoustically sensitive spaces.

Lower vibration also means tighter seals and fewer refrigerant leaks, helping extend system life and reduce maintenance, critical in locations where access is limited or service costs are high.

Garrett: Engineering the Future of HVAC

Garrett’s oil-free E-Cooling solution brings aerospace-grade precision and seven decades of turbomachinery and foil bearing expertise to the HVAC world. Built with the rigor of automotive manufacturing, it meets the demands of modern cooling, without compromise.

- Runs with low-GWP and natural refrigerants

- Delivers compact, high-power performance in tight spaces

- Up to 20% energy savings

- 75% smaller than legacy oil-lubricated systems

- Quiet, vibration-resistant, and built for long-term duty cycles

It’s not just an upgrade. It’s a smarter path forward.

Garrett is enabling the next generation of HVAC with compact design, oil-free reliability, and uncompromising performance.

Ready to future-proof your cooling systems? Explore the full E-Cooling solution on the Garrett product page.