What is a Hydrogen Fuel Cell Air Compressor? Advancing Clean Energy Tech with Garrett’s Expertise

In the automotive industry’s quest for sustainable and eco-friendly energy solutions, hydrogen fuel cells stand out as a promising alternative to traditional power sources. These devices electrochemically convert hydrogen fuel into electrical energy, producing only water and heat as by-products. This makes them a cornerstone of clean energy initiatives, particularly in the development of zero-emission vehicles.

Central to the efficiency and functionality of a fuel cell system is the fuel cell air compressor, a component in which Garrett Motion has made significant advancements, reinforcing its commitment to sustainable mobility solutions.

What is a Fuel Cell Air Compressor?

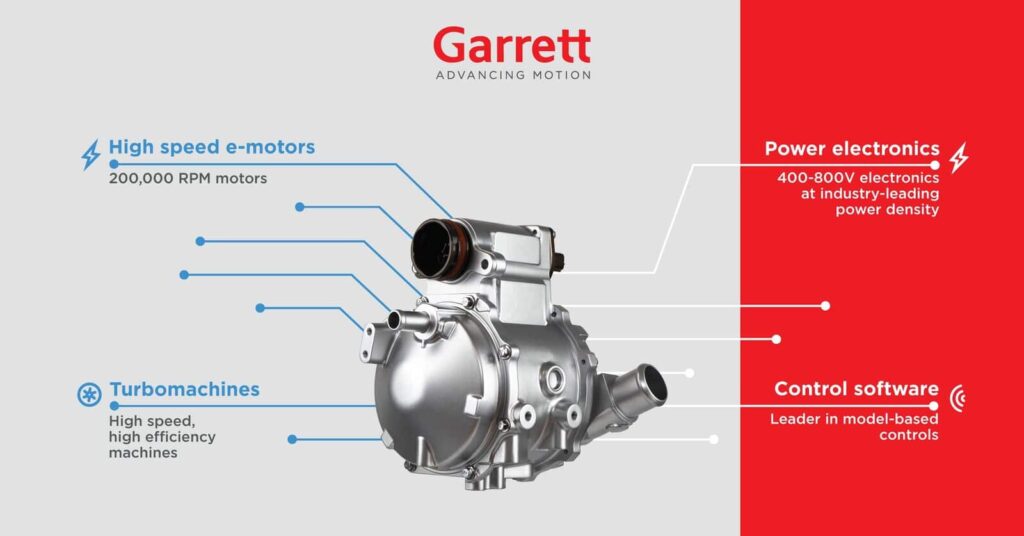

A fuel cell compressor is critical in fuel cell systems and Garrett Motion, a leader in clean energy technology, designs compressors combined with inverter controllers that optimize air pressure to feed the fuel cell stack, helping it produce energy.

This process enables the necessary reaction between oxygen (from the air) and hydrogen, producing electricity, water, and heat. Garrett’s fuel cell compressors are engineered for continuous and controlled air supply, ensuring stable and efficient fuel cell operation.

How does a Garrett Fuel Cell Compressor Work?

Garrett’s approach to fuel cell compressor design incorporates several key processes:

- Air Intake: Drawing ambient air efficiently through advanced intake systems.

- Compression: Utilizing differentiated techniques to compress air to optimal pressure levels, the high-pressure ratio electric compressors significantly increases the power density of Proton Exchange Membrane (PEM) fuel cells while reducing compressor noise.

- Air Delivery: Directing compressed air to the fuel cell stack’s cathode side, facilitating the electrochemical reaction that generates electricity and water vapor.

- Thermal Management: Implementing innovative thermal management solutions to dissipate excess heat generated during compression, preserving fuel cell system performance and longevity.

- Recirculation: Enhancing system efficiency through the strategic recirculation of air, optimizing the temperature and humidity conditions for the fuel cell.

How Efficient is a Garrett Fuel Cell Compressor?

The efficiency of a fuel cell compressor is crucial for the overall performance of the fuel cell system. Garrett’s engineering focuses on optimizing the balance between power consumption and air pressure delivery.

By developing compressors that maintain high efficiency without sacrificing fuel cell performance, Garrett plays a pivotal role in advancing hydrogen fuel cell technology. Innovations in component design, material selection, and engineering have yielded compressors that are not only efficient but also lightweight and durable, contributing to the enhanced performance of fuel cell systems.

Designed to meet the specific demands of fuel cell systems, Garrett’s compressors ensure a consistent supply of pressurized air, essential for stationary and automotive applications. Garrett’s compressors have a compact, low-vibration design which allows for seamless integration, further advancing the potential of PEM fuel cells in various sectors.

As the world moves towards greener energy solutions, fuel cells emerge as a key technology in the transition. At the heart of this transition are Garrett’s fuel cell compressors, vital for the efficient and reliable operation of hydrogen fuel cell powertrains. Through continuous innovation in compressor technology, Garrett is driving the fuel cell sector forward, offering cleaner, more sustainable alternatives to conventional power sources and contributing significantly to a sustainable energy future.

To learn even more about Garrett’s fuel cell technology and other zero-emissions products, click here.