Features

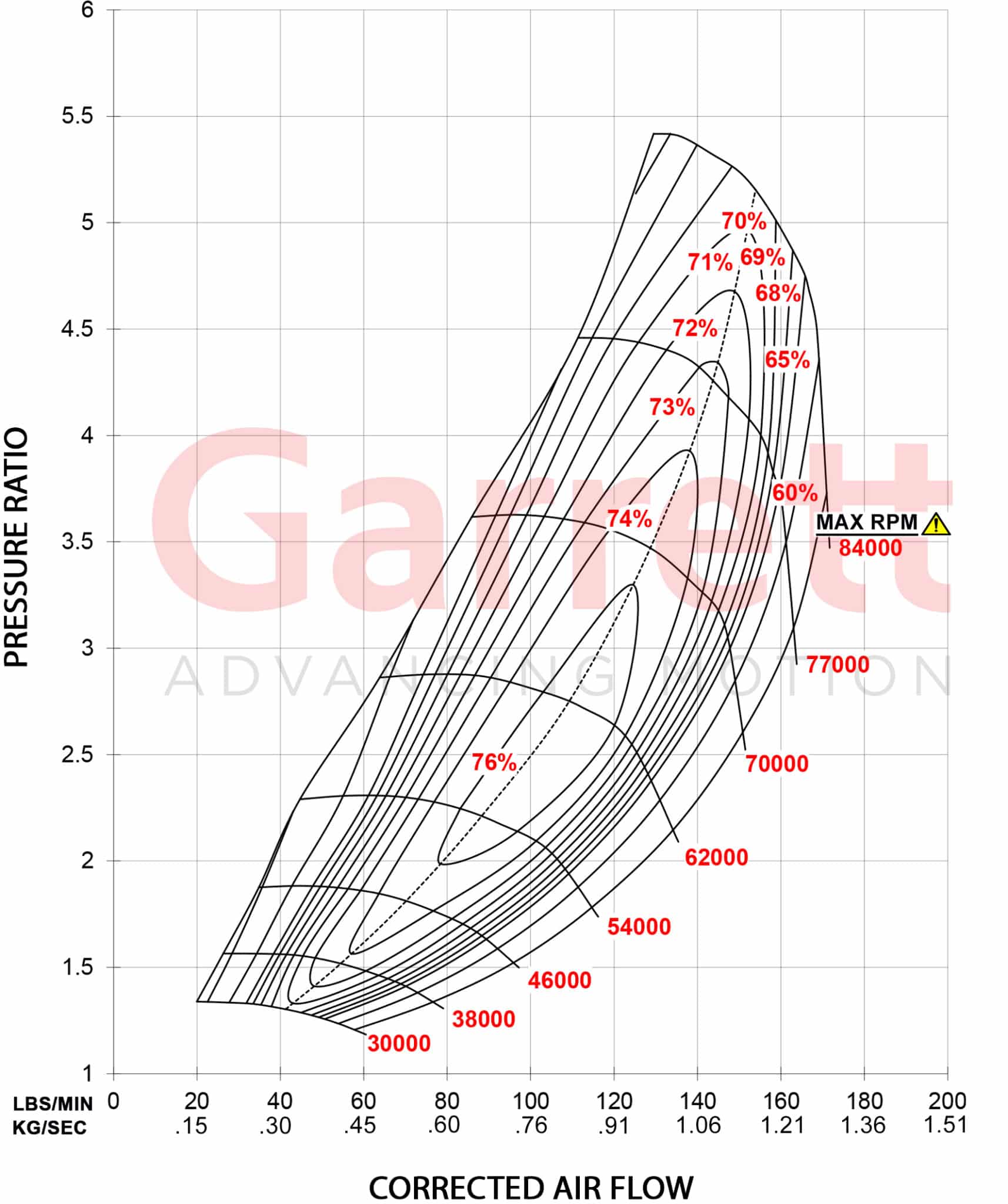

• Supports up to 2000 horsepower

• 88mm compressor inducer | 133mm compressor exducer

• 118mm turbine inducer | 112mm turbine exducer

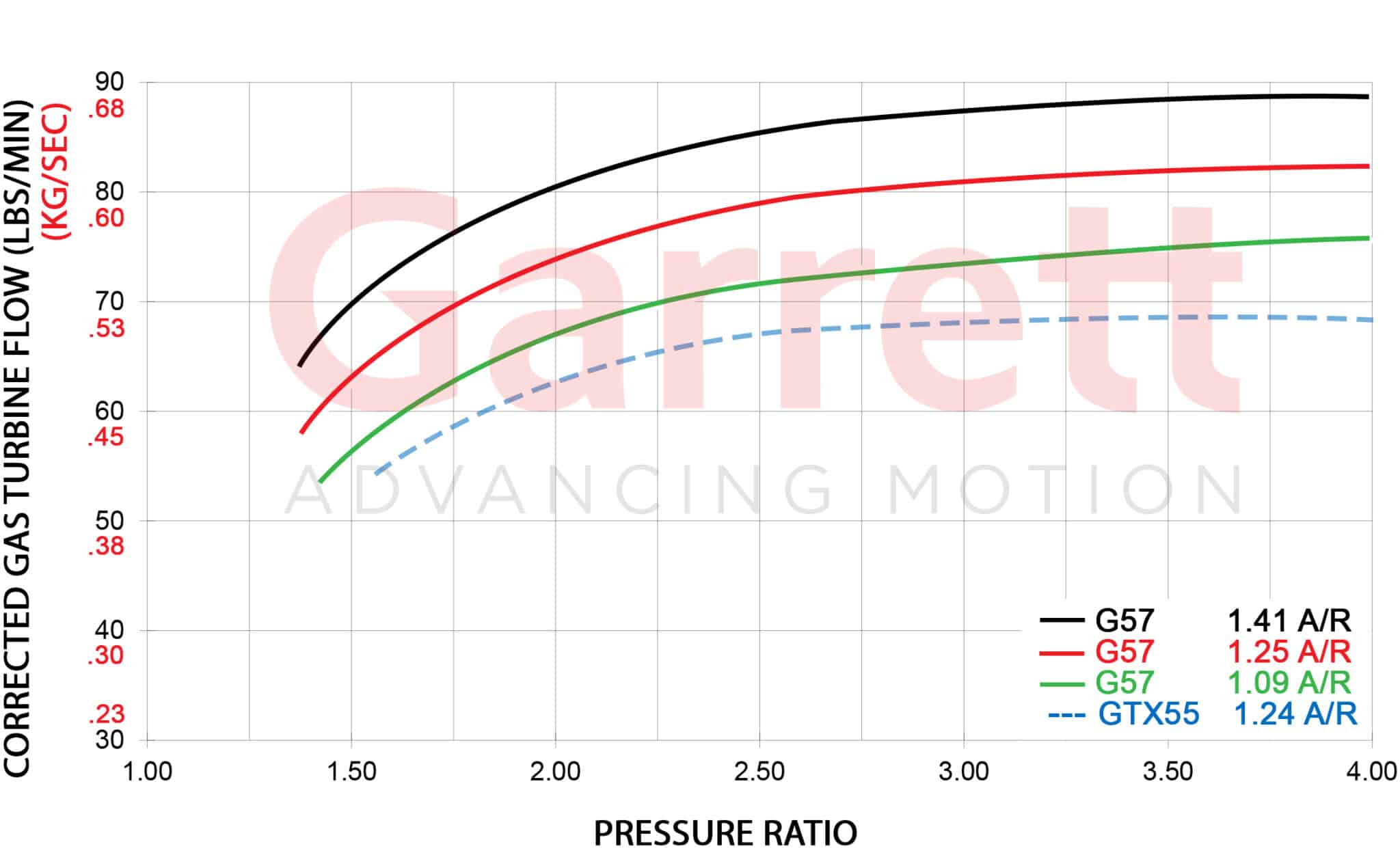

• 28% more turbine flow (compared to GTX) see graph below

• One-piece aluminum center housing

• 16mm dual ceramic ball bearing cartridge

• Outline interchangeable with GTX Gen II turbos

• Stainless Steel turbine kit sold individually. 1.09 A/R, 1.25 A/R, 1.41 A/R

- G57-2000 (88mm Compressor Inducer) 880547-5031S

WARNING: Maximum allowable turbocharger speed is 84krpm. The use of this product above max turbocharger speed is at the owner’s risk, and can result in damage and premature failure. To protect the turbocharger from overspeed when operating, a speed sensor can be installed into the compressor housing to monitor shaft speed. Sensors sold separately. (click here for details)

Performance results of this product are highly dependent upon your vehicle’s modifications and tuning/calibration. The horsepower numbers represented above are calculated based strictly on choke flow of the compressor map (total turbo capability), which represents the potential flywheel horsepower.

Buy now

IMPORTANT PRODUCT INFORMATION

“Garrett Performance Kits are professional aftermarket products only designed for certain racing vehicles driven on particular racing tracks and shall only be used on racing vehicles that will never be driven on public roads or highways. Garrett Performance Kits are not legal for the use in vehicles on public roads or other roads to which public road law applies. Any vehicle modifications using Garrett Performance Kits are AT YOUR OWN RESPONSIBILITY and AT YOUR OWN RISK. Only use Garrett Performance Kits in compliance with all applicable laws, regulations, and ordinances (including but not limited to emission, noise, operating license, performance, safety, and type-approval aspects). A vehicle modification using Garrett Performance Kits may particularly affect or void a vehicle’s warranty, operating license or type-approval. Moreover, only use Garrett Performance Kits in compliance with all applicable racing and racing track provisions. It is YOUR OWN RESPONSIBILITY AND RISK to ensure that your Garrett Performance Kit fits your vehicle and area of application. YOU MUST ENSURE LAWFUL AND SAFE OPERATIONS AT ANY TIME. You should particularly consult the owner’s manual and service manual of your vehicle. You should also contact your vehicle’s manufacturer to determine what effects modifications may have on important aspects such as safety, warranty, performance, etc. Only install and use Garrett Performance Kits if you have fully read and understood this important safety information and if you fully agree with the terms and conditions set forth therein.”

Learn More About Race Vehicle Setups

G-Series G57-2000 88mm

Reference Data

| G SERIES G57 | Compressor | Turbine | |||||

|---|---|---|---|---|---|---|---|

| HP: 1400-2000 Disp: 3.0L-12.0L | Inducer | Exducer | A/R | Inducer | Exducer | Trim | |

| Supercore | PN | ||||||

| G57-2000 | 880547-5031S | 88mm | 133mm | 0.88 | 118mm | 112mm | 90 |

| Turbine Kits: G57 | PN | A/R | Inlet | Outlet | Wastegate | Divided | |

| Free Float Turbine Housing | 761208-0083 | 1.09 | V-Band | V-Band | Free Float | N | |

| 761208-0084 | 1.25 | V-Band | V-Band | Free Float | N | ||

| 761208-0085 | 1.41 | V-Band | V-Band | Free Float | N | ||

G-Series G57-2000 88mm

Download Section

| File Name | View |

|---|---|

| Compressor Map 88MM Inducer | View |

| Compressor Map 94MM Inducer | View |

| Compressor Map 98MM Inducer | View |

| Compressor Map 102MM Inducer | View |

| Compressor Map 106MM Inducer | View |

| File Name | View |

|---|---|

| Configuration Guide | View |

| File Name | Link | View |

|---|---|---|

| Compressor Map | Download | View |

| Exhaust Flow Chart | Download | View |

| Product Photo | Download | View |

| Flange Diagram | Download | View |

| Speed Sensor Kit Installation Instruction | Download | View |

G-Series G57-2000 88mm

Compressor Map & Exhaust Flow Chart

Compressor Map

Exhaust Flow Chart

G Series: A Turn Ahead Of The Competition

G Series G57 turbochargers feature the latest innovations in turbocharger technology. Advanced compressor and turbine aero offer a range of high horsepower performance boosting solutions for 3.0L – 12.0L engine platforms. 88mm, 94mm, 98mm, 102mm, 106mm compressor inducer sizes produce up to 3000 horsepower for today’s top drag race eams.

Turbine Stage:

The newly engineered turbine wheel with optimized G Series aerodynamics increases flow up to 28% (Compared to GTX Gen II, see graph below). The large 90 trim turbine stage measures 118mm at the inducer and 112mm at the exducer. G57 is offered with three stainless steel V-band turbine housings in 1.09 A/R, 1.25 A/R, and 1.41 A/R.

Part Numbers

- 1.09 A/R: 761208-0083 (Stainless Steel V-band inlet & Outlet)

- 1.25 A/R: 761208-0084 (Stainless Steel V-band inlet & Outlet)

- 1.41 A/R: 761208-0085 (Stainless Steel V-band inlet & Outlet)

Center Housing:

One-piece aluminum center housing reduces supercore weight. The center housing is air cooled, features a 16mm dual ceramic ball bearing for premium rotor dynamics, and retains the oil inlet and outlet specifications from previous GTX designs.

Compressor Stage:

Garrett G57 compressor stages are offered in 88mm, 94mm, 98mm, 102mm, and 106mm inducer sizes each with their own horsepower ratings indicated in the model name.

Turbine Housings:

Stainless steel turbine housings

Short outlet (SFI certified not available)

(3) Turbine configurations: 1.09 A/R, 1.25 A/R, 1.41 A/R

V-band inlet: 4.25 inch (108mm) (same as GTX55)

V-band outlet: 5.15 inch (131mm) (same as GTX55)

Dual Ceramic Ball Bearing

An oil restrictor is recommended for optimal performance with ball bearing turbochargers.The G57 turbochargers utilize a massive 16mm dual ball bearing cartridge with steel cages. An oil pressure of 40 – 45 psi at maximum engine speed is recommended to prevent damage to the turbocharger’s internals. In order to achieve this pressure, a restrictor with a 0.040” orifice will normally suffice, but you should always verify the oil pressure entering the turbo after the restrictor in insure that the components are functioning properly. Recommended oil feed is -3AN or -4AN line or hose/tubing with a similar ID. As always, use an oil filter that meets or exceeds the OEM specifications.