Accessing the Knowledge Center effectively requires a simple, one-time registration.

Garrett Motion has officially expanded its next-generation G-Series II performance turbocharger line, adding six new large-frame turbos to complement the G25, G30, and G35 models released earlier this year. The latest additions—G40-1000, G40-1250, G42-1325C, G42-1325, G42-1585, and G45-1610—are designed for high-horsepower, high-pressure applications where every bit of efficiency and airflow matters.

New Garrett G42-1325 73mm

With upgraded center housing rotating assemblies (CHRA) and advanced compressor aero, the new G-Series II delivers up to 10% more compressor flow compared to Gen I at peak pressure ratio and turbo speed—unlocking measurable horsepower potential with proper tuning.

The Power of Legends, The Durability of Champions

For more than 40 years, Garrett has powered legends of motorsport—from endurance racing to top-tier competition, including Le Mans winners across the last 25 consecutive years. Behind that track record is a global engineering team of over 1,300 experts across five R&D centers, ensuring every product delivers both performance and reliability.

The new G-Series II brings that same motorsport DNA to kit makers, fabricators, and high-performance vehicle owners, offering a universal turbo solution designed to match the most demanding builds.

Technical Advantages

While G-Series II turbos retain the same compressor and turbine housings as Gen I, the gains are unlocked through a redesigned CHRA. Key advantages include:

- New compressor aero for up to 10% higher flow (vs. Gen I at peak Pressure Ratio and turbo RPM)

- Higher efficiency at high flow rates, increasing horsepower headroom

- Direct upgrade path via CHRA swap—no new housings required if exhaust and charge tube fabrication was involved

- Stainless steel turbine housings rated to 1050°C

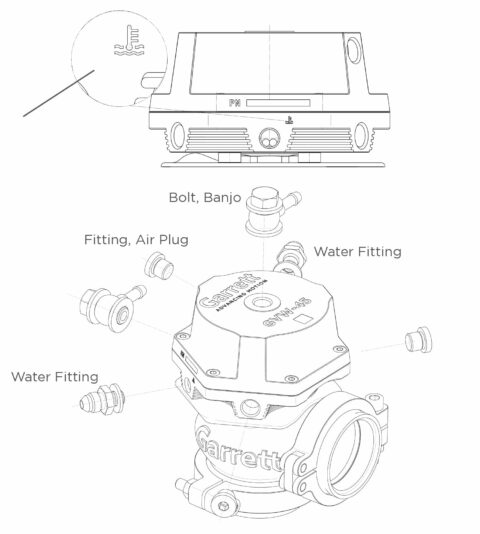

- Water fittings included for flexible installation

Direct Upgrade Path from Gen I

A simple CHRA swap transforms existing Gen I units into their Series II counterparts:

- G40-900 → G40-1000

- G40-1150 → G40-1250

- G42-1200 → G42-1325

- G42-1200C → G42-1325C

- G42-1450 → G42-1585

- G45-1475 → G45-1610

View G-Series II Turbos

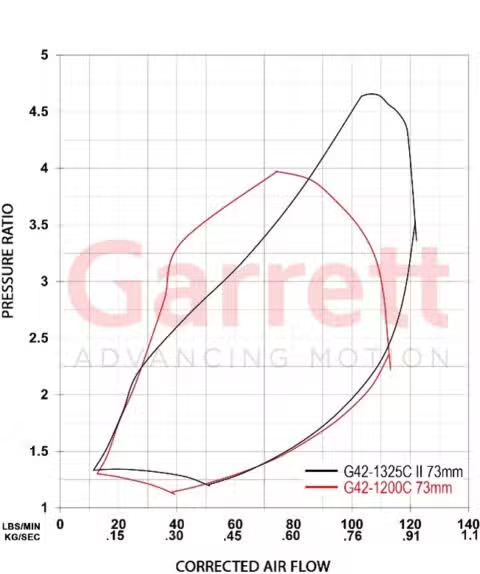

Compressor Map Overlays G40 and G42C

Overlay convention: Gen I = Red, G-Series II = Black.

Figure 1 — G40-900 (Gen I) vs. G40-1000 (G-Series II)

Summary: Gen II extends rightward flow capacity (higher lb/min). Peak PR is comparable as Gen I’s apex, but usable area at higher flow is clearly larger.

Figure 2 — G40-1150 (Gen I) vs. G40-1250 (G-Series II)

Summary: Gen II shows a clear rightward expansion (more max flow) and a higher top PR region than Gen I. Overall envelope is bigger at the top/right—ideal for higher power targets.

Figure 3 — G42-1200C (Gen I Compact) vs. G42-1325C (G-Series II Compact)

Summary: Despite the compact package, Gen II extends the map rightward and raises the top PR region. Better high-Pressure Ratio coverage in tight-bay applications.

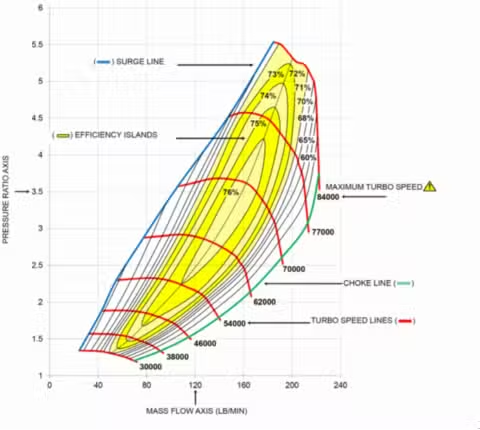

How to Read These Maps (Quick Reference)

- Axes: X = Mass Flow (lb/min), Y = Pressure Ratio (PR).

- Efficiency islands: Concentric rings; small center = highest efficiency. Efficiency decreases as rings move outward toward the boundaries.

- Boundaries:

- Surge line (left): Unstable flow (flutter/boost oscillation). Avoid. A bypass/BOV helps keep the operating point out of surge.

- Choke line (right, ≈ ≤58% eff.): Rapid efficiency drop and overspeed risk. If you’re here, you likely need a larger compressor.

- Turbo speed lines: Red RPM contours; farther right = higher flow & PR. Tight spacing near the right edge = overspeed risk. Do not exceed max speed.

- Rule of thumb (gasoline engine): ~10–11 flywheel hp per 1 lb/min of airflow.

- Example: target of 400 hp → will require ~36–40 lb/min. of airflow

- Converting CFM to mass flow at sea level: lb/min = CFM × 0.076 (lb/ft³).

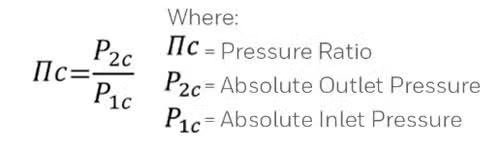

- Pressure Ratio:

Why These Gains Matter

The new CHRA aero increases compressor efficiency where modern high-output builds actually live: elevated pressure ratios, extended RPM, and long pulls where charge-air temperature control is critical. The result is more power potential for the same boost, or the same power at less heat and effort—both wins for durability and repeatability.

Compressor Map Overlays G42 and G45

Figure 4 — G42-1200 (Gen I) vs. G42-1325 (G-Series II)

Summary: Gen II delivers both higher max flow (further right) and higher peak PR (taller apex) relative to Gen I.

Figure 5 — G42-1450 (Gen I) vs. G42-1585 (G-Series II)

Summary: Gen II is larger in both dimensions—notably more flow beyond ~132 lb/min and a higher PR apex. Stronger top-end capability.

Figure 6 — G45-1475 (Gen I) vs. G45-1610 (G-Series II)

Summary: Gen II sustains substantially more flow at the right boundary and reaches a higher peak PR, ideal for large-displacement/high-RPM builds ready for LOTS of boost.

Designed for Builders and Enthusiasts

Whether you’re developing a new turbo kit or upgrading an existing high-performance build, the G-Series II line now spans from G25 through G45, covering a wide spectrum of power levels.