Garrett G30-660 and G30-770 Turbochargers Combine High Flowing, Efficient Aero In A Compact Package

The Garrett G30-660 and G30-770 Turbochargers

Garrett G Series turbochargers feature advanced compressor and turbine aero to offer enthusiasts a wide range of performance boosting solutions for 2.0L – 3.5L engine platforms. The G30-660 and G30-770 are available in standard and reverse rotation options for twin turbo applications or for turbo setups that need a reverse rotation turbo like the Mitsubishi Evo 4 – 9. Turbine housings are offered in a variety of stainless steel configurations making it easy mount and tune your application. The dual ceramic ball bearing cartridge helps improve boost response and durability.

New G Series 30 turbochargers have a larger trim compared to GTX models. Wheel trim is a ratio of the inducer to exducer of a compressor wheel and exducer to inducer of the turbine wheel. The larger the trim, the less difference you have  between inducer and exducer.

between inducer and exducer.

Compressor Trim = (inducer² / exducer²) x 100

Turbine Trim= (exducer² / inducer²) x 100

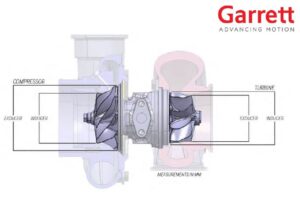

Compressor Inducer 54mm | Compressor Exducer 67mm

Turbine Inducer 60mm | Turbine Exducer 55mm

Compressor Inducer 58mm | Compressor Exducer 71mm

Turbine Inducer 60mm | Turbine Exducer 55mm

Compressor Stage Features

- Standard and reverse rotation configurations for all G30 models

- Fully machined ported shroud to help reduce compressor surge

- Speed sensor port provides racers the option to add a speed sensor. Comparing shaft speed and boost levels on a compressor map will help determine ideal operating conditions to ensure peak power over a wider operating range.

- Speed Sensor Kits: G Series speed sensor kits have new part numbers and are notcompatible with GT/GTX kits. Easier to install and does not need to be adjusted for length like previous sensors. Simply remove bolt that secures the plug, insert the speed sensor and re-tighten the bolt.

- G Series Street Kit: 781328-0003 (includes speed sensor, wire harness, gauge)

- G Series Pro Kit: 781328-0004 (includes speed sensor, wire harness)

- Fully machined pressure port. Used to supply external wastegates with pressure signal.

- An O-ring between the compressor housing and backplate reduces any boost pressure leakage.

Center Housing

- Water cooled design allows optimum cooling

- 4 water ports provide more installation options

- Water fittings, plugs, and oil restrictor included (.035” restrictor)

- One piece center housing and backplate

- Center housing to turbine housing V-band connection to make installation quick and easy

Aerodynamics and Rotor Group

Compressor Wheel

CFD engineered, forged fully-machined compressor wheel

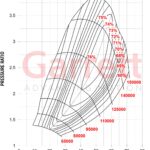

Wider compressor maps for a larger operating area

9 blade count

Bearing

8mm dual ceramic ball bearing

Twin piston rings on comp and turbine stage

Turbine Wheel

Mar-M Turbine wheel construction

High temperature rated up to 1050°C | 1922°F

Turbine flow is 5% higher than GTX

Turbine Housings

- V-band configurations have 360 degree clockability

- Stainless steel turbine housings for temperatures up to 1050°C | 1922°F

- 3 inch (76.2mm) V-band inlet (same as GTX)

- 3.5 inch (90.16mm) V-band outlet (same as GTX)

- V-band 0.61 and 0.83 configurations available at launch

- Additional housing configurations TBD

Features:

• New G Series compressor wheel aerodynamics

• Fully machined speed sensor and pressure ports

• Standard and reverse rotation configurations available

• Oil restrictor and water fittings included with purchase

• One piece center housing and backplate for increased durability

• 4 water jacket ports for customizable installation

• Mar-M turbine wheel material rated up to 1050° C | 1922° F

• Stainless steel turbine housings for temperatures up to 1050° C | 1922° F

For more information visit us on Facebook at https://www.facebook.com/garrettmotion/