Garrett Intercooler Core Technology | Proven Thermal Performance

Engineered to preserve air density and thermal stability

Garrett Intercooler Core Technology

Advanced cooling for high-performance engines

This page connects intercooler core engineering, including bar-and-plate construction, advanced internal fin geometry, and optimized fin density, to measurable real-world performance results using high-load testing data supplied by do88 AB in a high-output Audi RS6 application. Garrett intercooler cores are available through authorized performance distributors worldwide.

Explore Garrett Intercoolers |

Skip to the Test Results |

Why core design matters

As turbocharged engines increase in airflow demand and power density, intercooler performance becomes a determining factor in sustained output. Peak cooling is important, but thermal stability under repeated load is what ultimately defines consistency.

Cooler charge air is denser than hot air. Increased air density allows more oxygen molecules to enter the combustion chamber at a given boost pressure. More oxygen supports greater combustion efficiency, which directly enables higher potential power output.

When intake air temperatures rise, density decreases and the engine control system may reduce timing or boost to protect components. Effective intercooling therefore does more than manage temperature. It preserves air density, supports combustion efficiency, and helps maintain consistent power delivery under load.

Inside the Garrett core

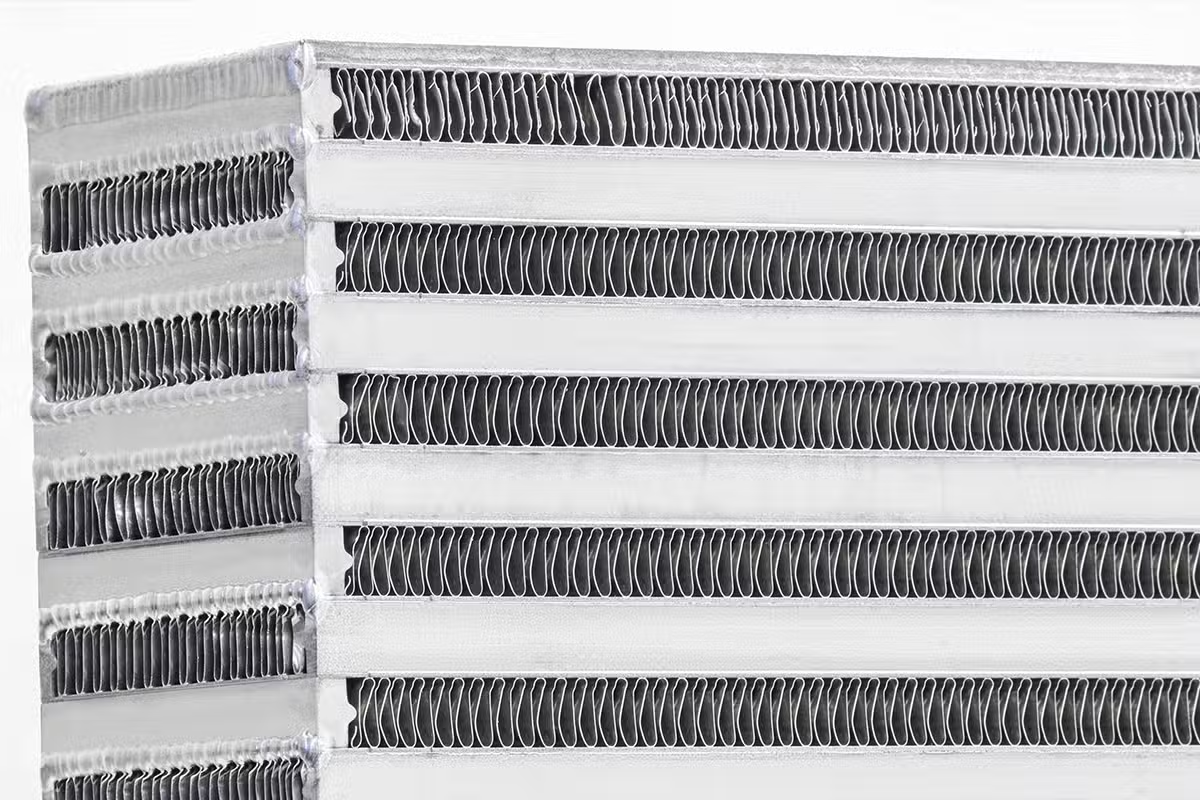

Bar-and-plate construction

Bar-and-plate architecture provides increased thermal mass and structural integrity. This helps the system absorb and dissipate heat effectively during repeated high-load events while maintaining durability.

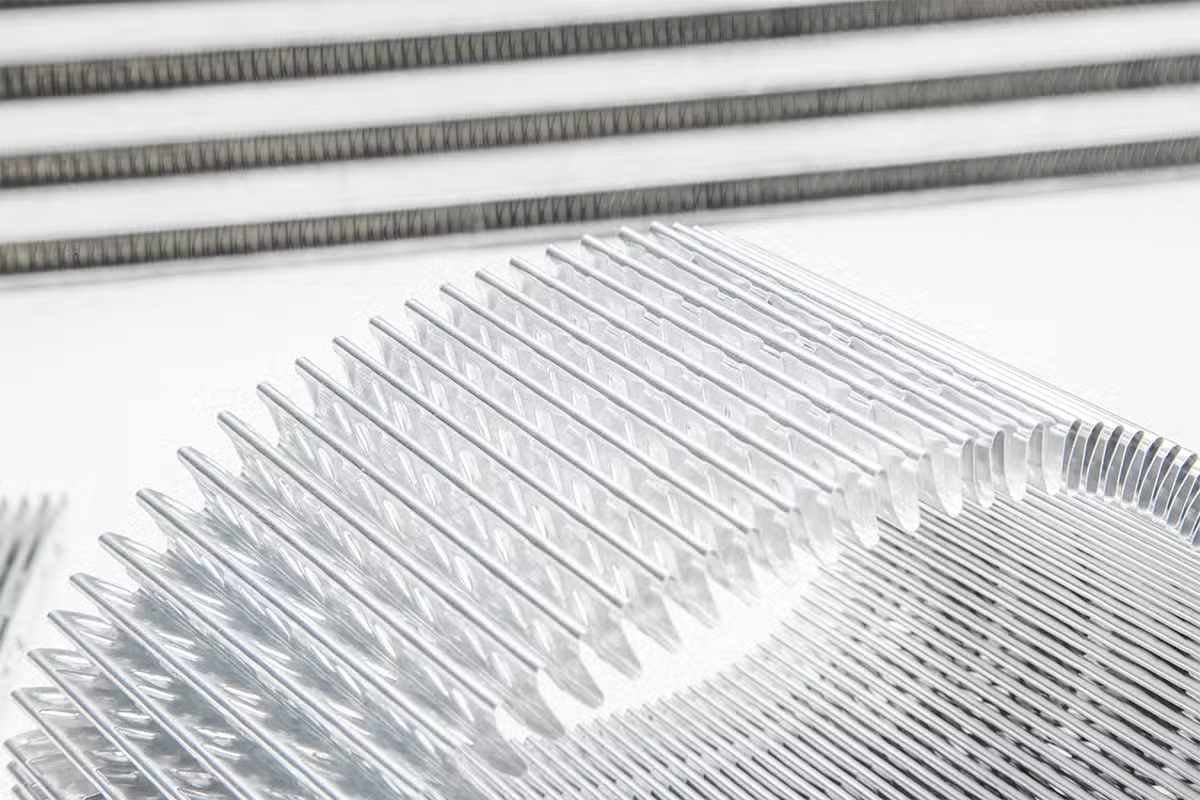

Advanced internal fin geometry

Offset internal fins promote controlled airflow turbulence within the core, increasing heat transfer efficiency without introducing unnecessary restriction.

Optimized fin density

Fin density is engineered to balance cooling effectiveness and airflow efficiency, supporting strong heat rejection while maintaining low pressure drop.

Validation overview

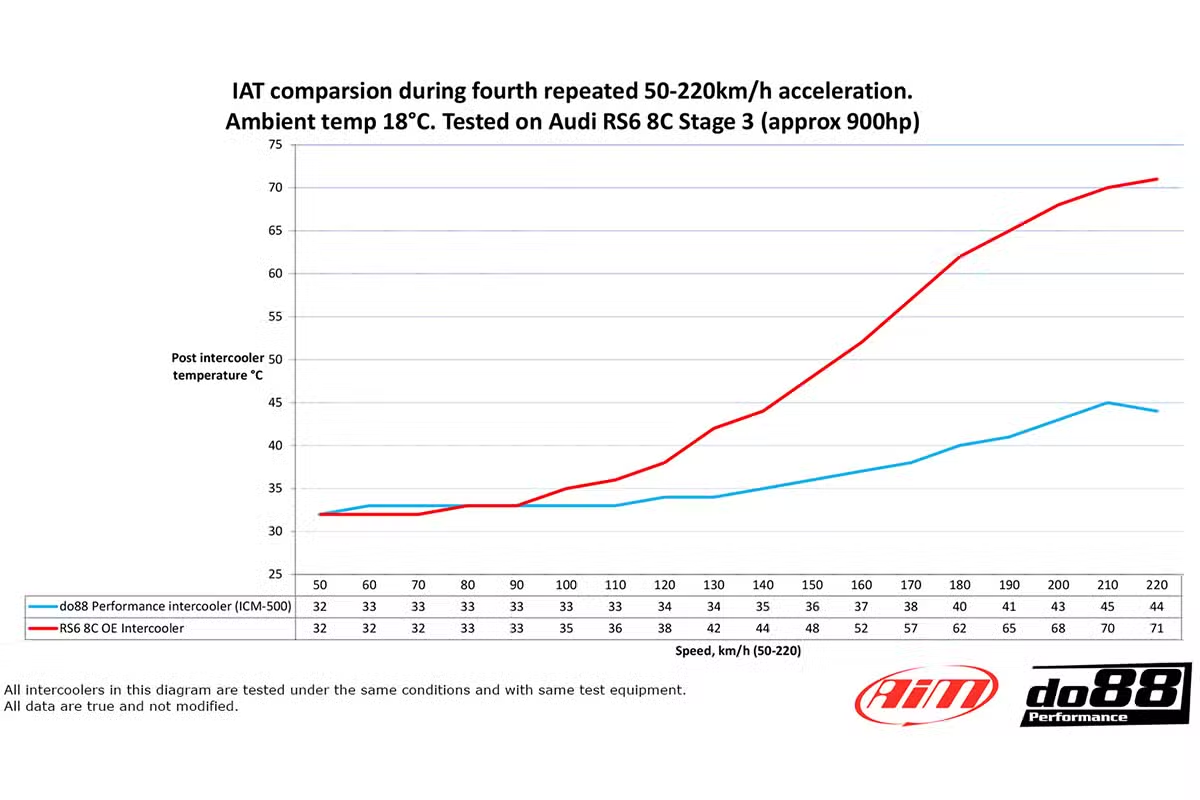

Testing data for this validation was supplied by do88 AB, a performance cooling system developer based in Sweden.

do88 supplied controlled test data from a 2020 Audi RS6 producing approximately 900 horsepower. Testing consisted of repeated full-throttle acceleration cycles from 50 to 220 km/h with minimal recovery time between runs.

This test scenario places significant thermal demand on the charge-air cooling system, allowing intake air temperature behavior to be evaluated under sustained load.

Test hardware note: The do88 intercooler tested uses a Garrett bar-and-plate intercooler core, manufactured by Garrett to do88-requested specifications and size, with do88-designed end tanks welded into a complete do88 intercooler assembly for the RS6 platform.

Performance results

Under repeated acceleration cycles, the original equipment intercooler exhibited progressive intake air temperature rise, eventually triggering ECU power reduction.

- Peak intake air temperature reduction of approximately 27°C

- Average IAT reduced from approximately 43°C to 32°C

- Stable temperature behavior across repeated cycles

- Reduced likelihood of heat-induced power derate

The data indicates improved thermal stability rather than simply lower peak cooling during a single event.

This distinction is critical in high-performance applications.

Airflow and efficiency

Effective intercooling requires strong heat rejection without excessive pressure drop. Excessive restriction increases turbocharger workload and system heat generation.

Garrett cores are engineered to support airflow efficiency alongside cooling capacity, helping maintain boost targets and consistent performance under demanding conditions.

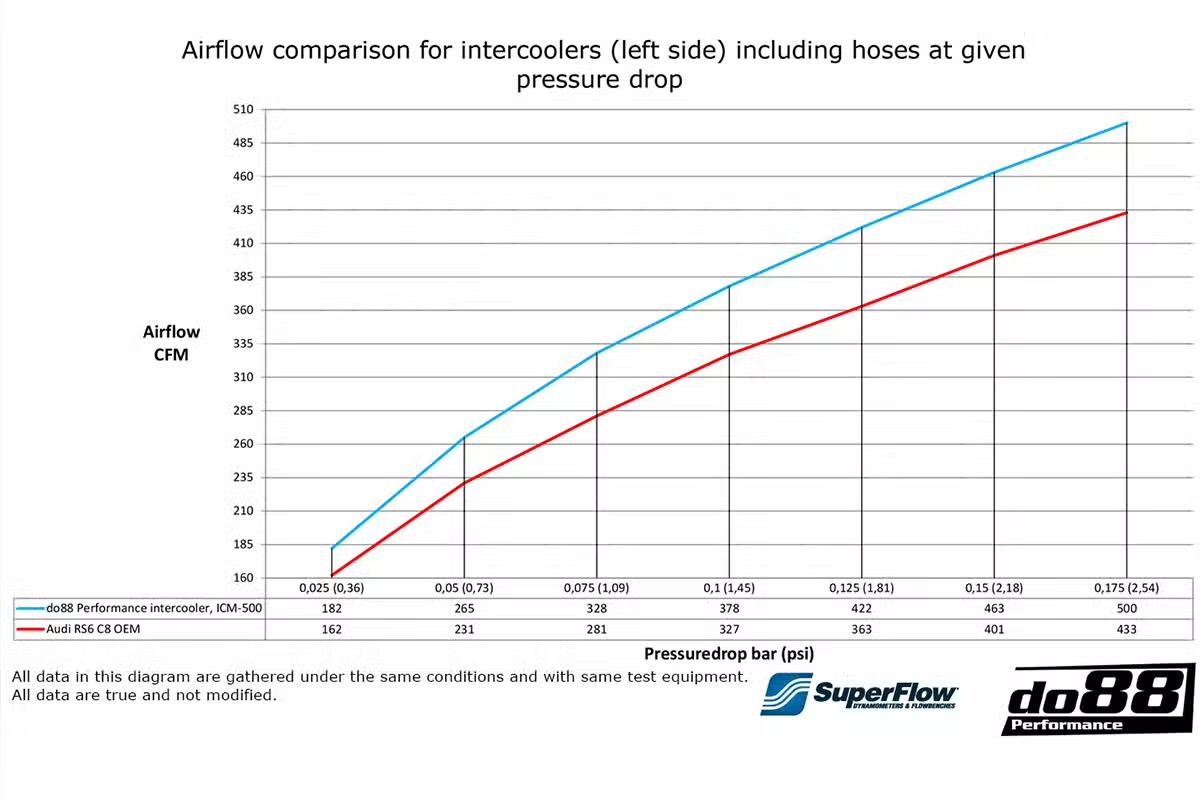

With the Garrett-supplied core built to do88’s specifications and packaged in do88’s end-tank design, airflow increases at a given pressure drop (for example, approximately 378 vs 327 CFM at 0.10 bar (1.45 psi), including hoses). More flow at the same ΔP means less restriction and a more efficient path to stable power.

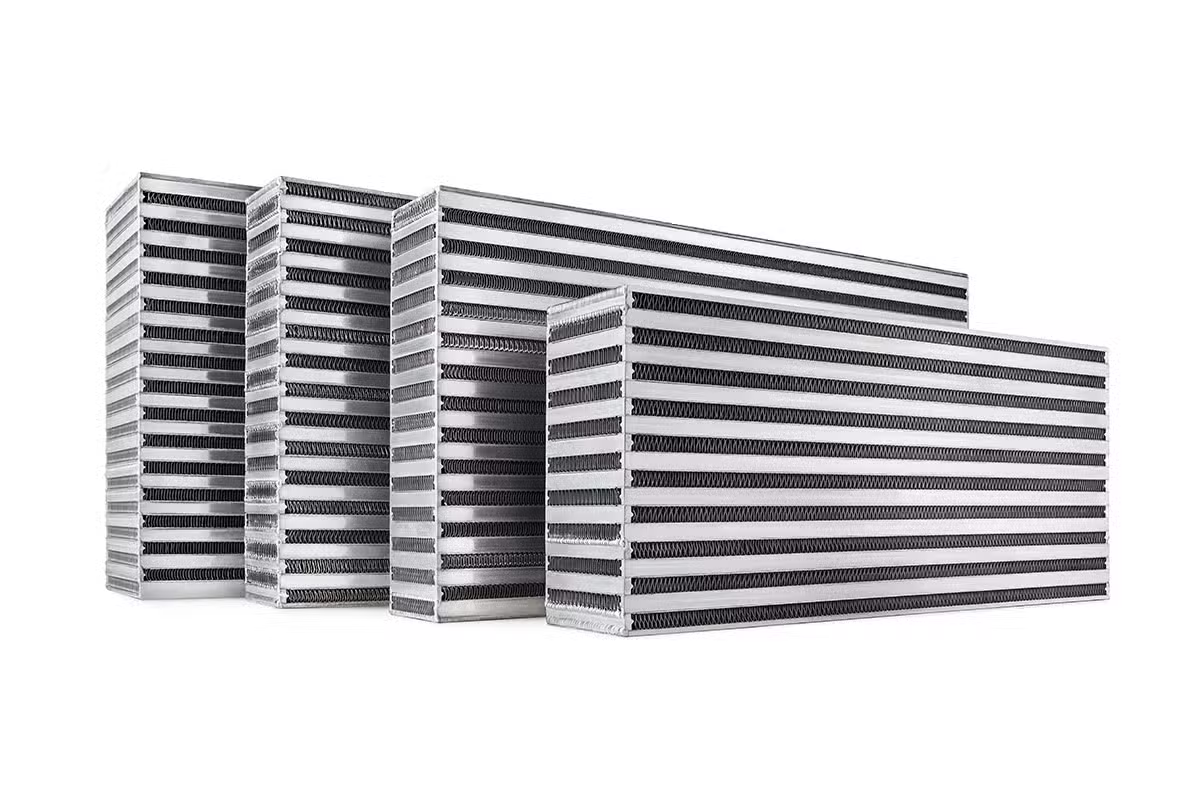

Core platform and available options

Garrett intercooler solutions are available in multiple air-to-air and air-to-liquid configurations supporting a wide range of horsepower targets. This allows system developers to match packaging constraints with airflow and thermal requirements.

Ready to integrate Garrett cores?

Garrett intercooler core technology is available through authorized performance distributors worldwide. Contact your local Garrett dealer to discuss core sizing, availability, and integration support.

Download the Engineering Validation Guide

Review the full technical breakdown, validation data, and core platform overview in a downloadable PDF format.