Accessing the Knowledge Center effectively requires a simple, one-time registration.

Garrett Performance announces the latest addition to the G Series Turbocharger lineup with the G40-900 (62mm) and G40-1150 (71mm) turbochargers. These turbochargers are engineered for 2.0 liter up to 6.0 liter engine displacements and can support up to 1150 horsepower. G Series turbochargers are more advanced than previous generations like GT, GTX, and GTX Gen II. G Series 40 turbochargers designed to replace and the GTX4088R and to be the step between G35 and G42 turbos.

G Series G40 Compressor Stage Features

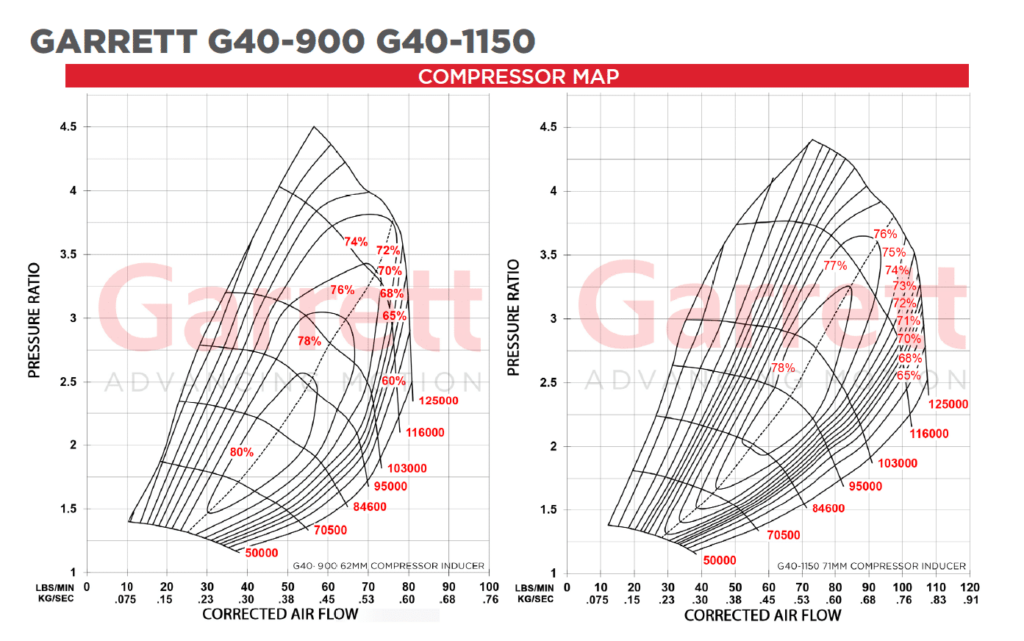

G40 is offered with two compressor sizes, G40-900 62mm compressor inducer (51 trim), and the G40-1150 71mm compressor inducer (65 trim). Both compressor wheels have an 88mm exducer and that’s why they have a different trim. Wheel trim is the relationship of inducer to exducer and can be calculated using this formula: compressor (Inducer² / Exducer²) x 100. G40 compressor wheels feature a high flowing, 10 blade compressor wheel that increases flow up to 32% compared to the GTX4088R turbo. G40-900 has a maximum compressor efficiency of 80% and you can see the peak efficiency island is lower on the compressor map which can be more beneficial for setups at low pressure ratios. The G40-1150 has a maximum efficiency of 78% and the peak efficiency island is higher and more centralized in the compressor map which can be more beneficial for engine setups at higher pressure ratios.

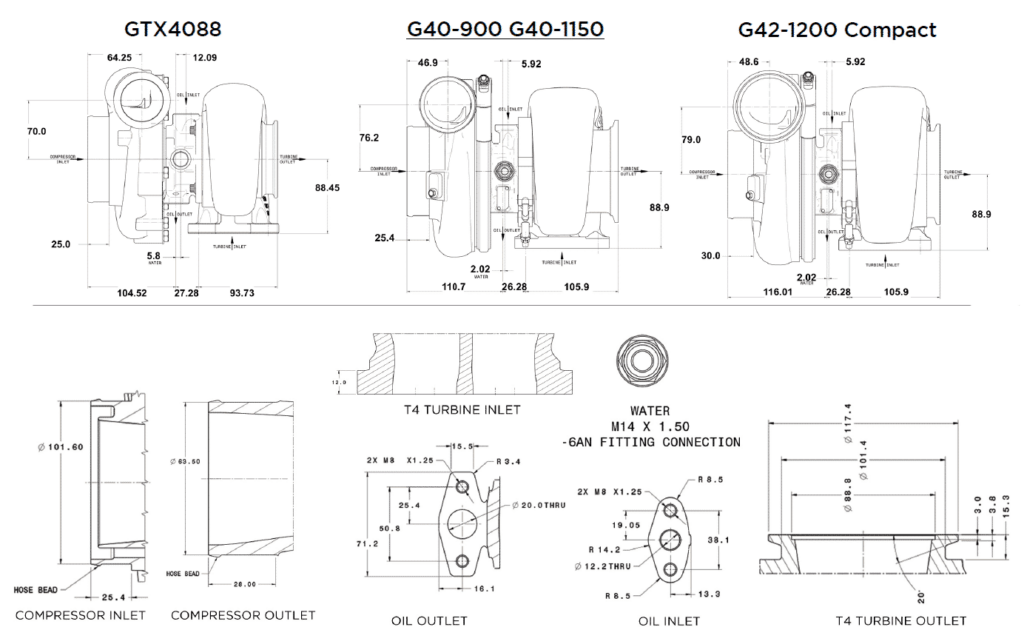

G40 turbochargers utilize the same compressor housing for both sizes, however, the inlet and contour is machined for each compressor option. They are not interchangeable in case you were wondering and if you happened to put the larger compressor housing on the smaller wheel the flow and efficiency would be horrible so it’s not worth even thinking about trying. The compressor inlet has a slip hose connection with 101.60mm / 4 inch diameter. The compressor outlet also has a slip hose connection with 63.5mm / 2.5 inches in diameter. A fully machined speed sensor port can accept the G Series style speed sensor ( 781328-0003 street kit, 781328-0004 pro kit). Speed sensors are easy to install and calibrate and can help fine tune your setup as well as provide a failsafe to overspeed when used with a performance ECU. G40 compressor housings also have a fully machined and threaded pressure port for your wastegate signal. G40 features a V-band connection for the compressor housing to center housing attachment. Lastly the fully machined ported shroud helps protect the rotating assembly if there is turbo surge.

G Series G40 Turbine Stage Features

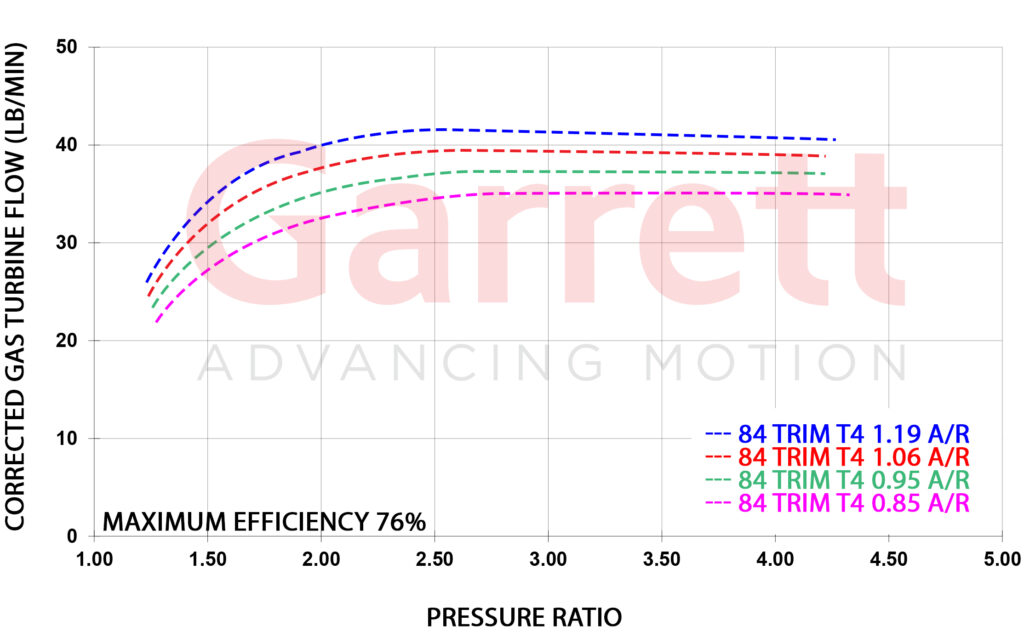

Both G40 turbochargers share the same turbine wheel and turbine housings and in fact every frame size in the Garrett portfolio does. For example, G40 has 2 turbos and both use the same turbine wheel, and both use the same turbine housings. In the case of GT, GTX Gen I, and GTX Gen II turbos all three use the same turbine wheel for instance the GT3582R, GTX3582R Gen I, and GTX3582R Gen II all use the same turbine wheel and same turbine housings. Now, back to G Series. G40 turbine wheels are made from Inconel, a very durable, and heat tolerant material. The G40 turbine wheel has a 77mm inducer and a 70mm exducer making it an 84 trim wheel. The aerodynamic design of this wheel increases flow up to 16% when compared to the GTX4088R. This is important because it allows the performance and response of the smaller turbine wheel to support engine displacements from 2.0 liter up to 6.0 liter. A higher flowing turbine wheel means lower backpressure, and higher efficiency so if you are trying to squeeze a little more out of the turbo you can.

Max turbine wheel efficiency of the G40 turbine wheel is 76% compared to the GTX4088R at 66% so there’s a huge improvement in aero between the two turbos. Let’s talk about flow between the two, and for this example we will look at the larger of the turbine housings 1.19 A/R T4 turbine housing. G40 1.19 A/R has a max flow of 43 lbs/min and the GTX4088R 1.19 A/R peaks at 37lbs so there’s a 16% increase in peak turbine flow. Four stainless steel turbine housings are available with a T4 inlet flange, 0.85 A/R, 0.95 A/R, 1.06 A/R, and 1.19 A/R. Turbine housing to center housing attachment is with V-band connection. One point to mention is the G40 and G42 turbine housings are machined from the same castings so they share the same outline dimensions, and same outlet specs (117.4mm / 4.6 inch). This is beneficial if someone wanted to change turbos for different races or if upgrading or downgrading from one to the other. The G40 will be a great option for all the popular and highly modified straight six engines and a really fast spooling option for V8 5.3 liter and LS engines up to 6.0 liters.

G40 vs G42-1200 Compact vs GTX4088R

The diagram shows all the flange specs of the G40-900 and G40-1150 turbo and it also gives a side by side view of how it compares in size to the G42-1200 Compact and GTX4088R turbos.

Conclusion

G40 is a product we are extremely happy to release in part because we never launched a GTX Gen II version of the 4088 so this is a long awaited product that racers have been waiting for. To see more about the turbo including part numbers click the button below. If you are interested in pricing click the where to buy button to find a distributor near you and last but not least stay tuned for more articles on G40 performance when we see our first dyno data! Thanks for reading.