ENHANCING FUEL EFFICIENCY, DURABILITY AND PERFORMANCE

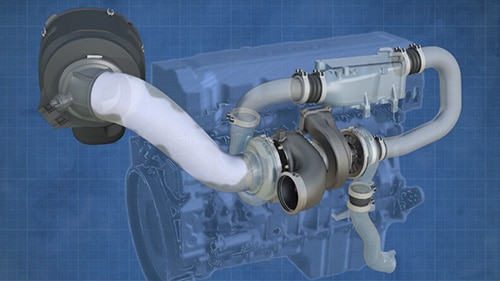

On- and off-highway, sometimes it pays to compound the benefits of turbocharging by having two turbos in a series arrangement – for improved transient performance, better low-speed torque, longer turbo life and optimized fuel efficiency.

Engine Range

Garrett Two Stage turbo systems are increasingly being adopted across a wide range of applications – from small downsized 4.4L construction vehicles to heavy-duty trucks and massive 64L mining equipment. Tougher emissions requirements are making this technology also particularly attractive for smaller displacement medium-duty engines.

Commercial Vehicle Two Stage Serial Turbochargers Key Features

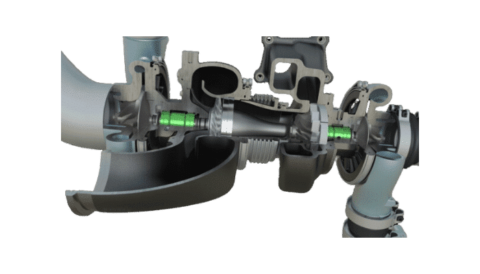

In two-stage series turbocharging, fresh air is drawn into the first stage compressor, where its pressure is raised about 2 to 2.5 times atmospheric pressure. This pressurized air is then drawn into the second stage compressor, where the pressure is raised another 2 to 2.5 times. The air is then cooled and the resulting charge air at the engine’s intake manifold is typically 4 to 5 times that of atmospheric pressure – and about 20°C higher than ambient temperature. By splitting the compression of the charge air between two turbos, both compressors operate at peak efficiency. Also, the lower pressure ratios for each stage mean lower rotating speeds, which results in improved reliability for the bearing systems, compressor wheels and turbine wheels.

ENHANCING FUEL EFFICIENCY, DURABILITY AND PERFORMANCE

Commercial Vehicle Two Stage Serial Turbochargers Benefits

Garrett Two Stage Serial turbocharging offers the biggest benefits to engine suppliers who use Miller cycle or Atkinson cycle engines.

Evolution and Future Trends

Garrett is a pioneer in the Two Stage technology. First developed for high-altitude mining equipment in the early 1990s, Two Stage turbo system was then adopted for high-volume on-highway truck engines in 2003. While most Two Stage systems incorporate advanced wastegate and free-floating turbos, some OEMs are also opting for Two Stage systems that include variable geometry architectures to meet specific power and low end torque criteria and to drive the high pressure EGR.

Two Stage turbo technology will see wider adoption around the world due to its inherent ability to help meet performance and emissions goals while maintaining system robustness. Garrett engineers are committed to strengthen the company’s leadership in this technology through advances in aerodynamics, bearing and sealing systems and materials.