What Are The Advantages Of An Extended Tip Compressor Wheel

Have you ever wondered how long extended tip compressor wheels have been used or why they are used in modern turbochargers? The extended tip compressor wheel has been used

Learn moreWastegates and Blow Off Valves are both designed to vent air, however, they are engineered for two different types of air flow.

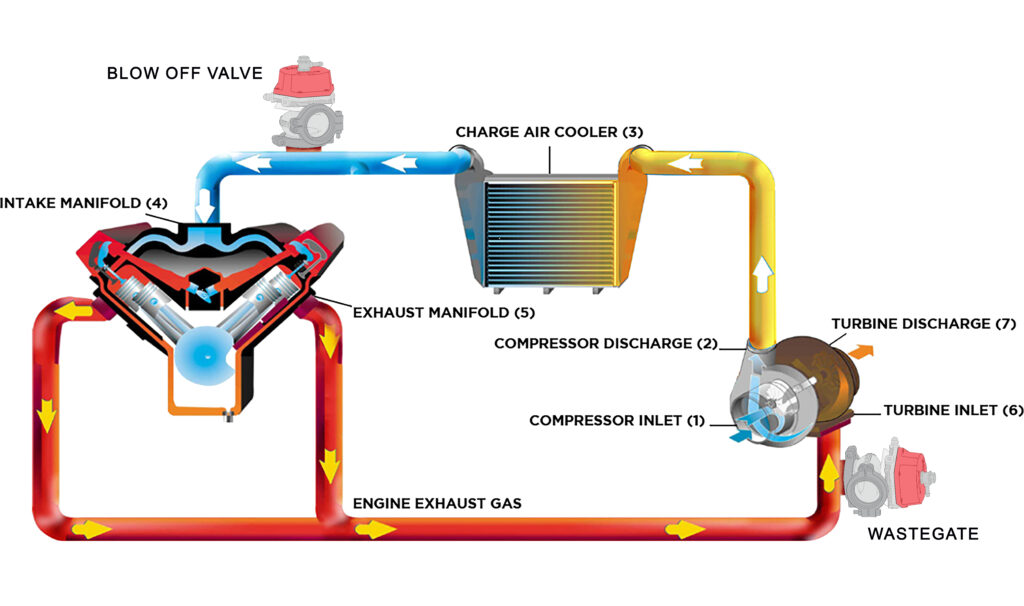

Turbo Wastegates are placed on the exhaust gas side of a turbo system and are used to control turbo speed. Turbo Blow Off Valves are placed on the boost side of the turbo system and are used to vent boost in the intake tube once you let off the gas pedal, to avoid damaging the turbo.

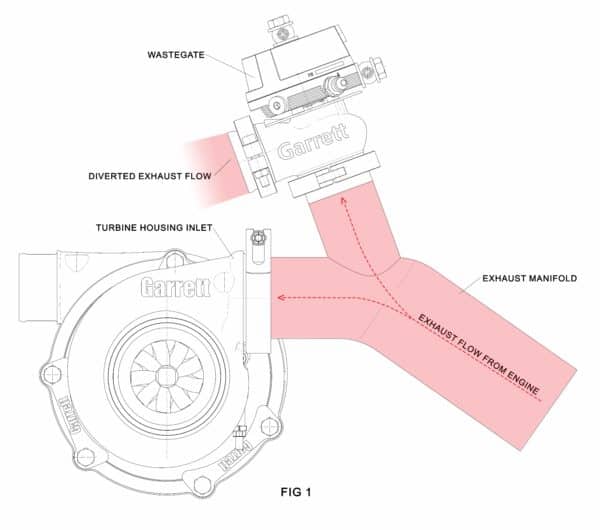

External Wastegates regulate turbocharger shaft speed by venting exhaust gas around the turbine stage of the turbocharger. A wastegate is placed on the exhaust manifold before the turbine housing inlet (Fig 1).

The faster an engine revs, the more exhaust air it flows to the turbine housing, and the faster the turbo spins. Most applications do not need all of the boost from the turbo and the only way to limit the boosted air a turbo produces is to slow the turbo down. The only way to slow the turbo down is to reduce the exhaust air flow to the turbine housing by venting it out of the external wastegate.

A wastegate opens based on the PSI rating of the springs that are contained inside the cap. These springs sit on top of the valve and diaphragm and apply a downward (closing) pressure on the valve. Springs can be adjusted from 0.2 Bar | 3 PSI up to 1.7 Bar | 25 PSI meaning it will take that amount of positive pressure (boost) to fully open the valve. Positive pressure (boost) is fed to the space below the diaphragm and once the pressure starts to equalize or exceed the spring rate, the valve will open and vent exhaust air to stabilize the turbo RPM.

Blow Off Valves are placed on the charge air side of the turbo system. Its main role is to vent boosted air out of the charge air tube once you let off the throttle and the throttle body is closed. If you rev the engine to a high RPM and let off the gas, the turbo is still spinning and creating boost. The boost is now trapped in the charge air tube, and intercooler, and if there’s a lot of pressure buildup the air will force its way out of the turbo causing compressor surge. Compressor surge creates stress on the shaft and bearing assembly causing extra wear to the turbo.

A Blow Off Valve uses a pressure signal from the intake manifold that is fed to a fitting in the top cap. When the engine is in acceleration and creating positive (boost) signal, the air pushes the valve down to keep it closed. If you let off the throttle, the pressure signal from the intake manifold becomes negative (vacuum) and it now pulls the valve open and vents the charge air out of the charge tube.

If you look at the diagram you can see how the turbo system works. Air flow is cyclical, it starts at the turbo, goes through the intercooler and into the intake manifold, then it is fed to each engine cylinder for combustion, from there it is considered exhaust, the exhaust flows through the exhaust manifold bypassing the wastegate, and into the turbine housing inlet to spin the turbine wheel, and finally the exhaust leaves the turbine housing outlet where it is directed to the exhaust pipe. The blue/yellow highlighted piping is the compressed air (boost) from the turbo, and the red is the exhaust air flow path.

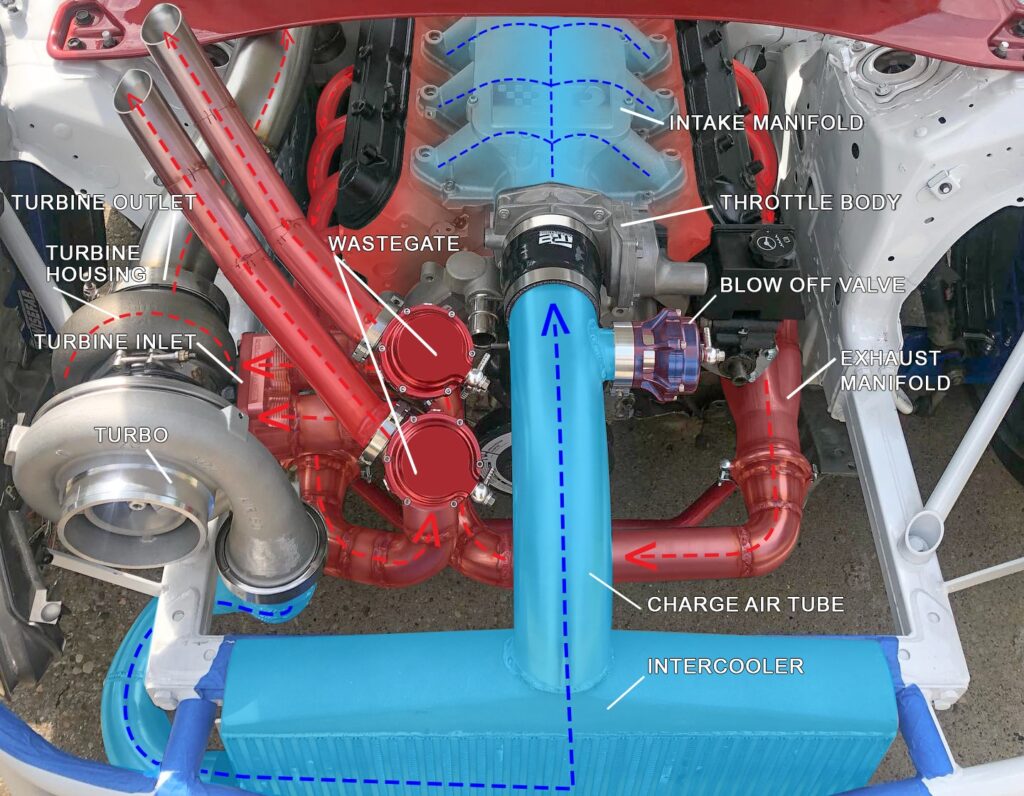

In this image, we have an engine bay with an LS, 8 cylinder engine, single turbo configuration, two wastegates, and one blow off valve.

In V configuration engines it is common to see a wastegate for each of the manifold runners, this provides more accurate control over the turbo speed.

That’s the difference between wastegates and blow off valves.

For more information on Garrett GVW wastegates please visit our product page.