Accessing the Knowledge Center effectively requires a simple, one-time registration.

How Turbocharger Wastegates Work – Internal vs External

What is a turbo wastegate and how does it work? What is is an internal wastegate vs an external wastegate? How do you select the best wastegate setup for your vehicle? If you have asked yourself these questions before, the video below from Moto IQ has all the answers for you. Listen to Mike Kojima as he explains all of the details of the new Garrett GVW wastegates and how and when to use them.

What Is A Wastegate?

A wastegate is a spring loaded valve that allows exhaust gasses to bypass the turbine of a turbocharger.

What Does A Wastegate Do?

Wastegates allow exhaust gasses to bypass the turbine of a turbocharger, regulating its speed (RPM), when a specific spring pressure is reached (referenced by a turbocharger’s boost).

How Does A Wastegate Work?

Wastegates can be controlled in several ways but the way they work out of the box is by referencing the turbochargers boost pressure. The spring/s inside the housing are rated for various pressures. Garrett GVW wastegates are calibrated to 14.5 PSI | 1 Bar of pressure. A boost pressure reference line is run to a port on the lower wastegate housing filling it with boost from the turbo. As the turbo spins faster, it makes more boost. Once the boost signal starts to reach the spring pressure, the valve will start to lift/open, allowing air to bypass the turbine of the turbocharger. Bypassing exhaust air around the turbine regulates the RPM of the turbocharger so it cannot make more boost pressure than the combined spring pressure. (if the valve is sized properly)

What Is The Difference Between Internal And External Wastegates?

Internal and external wastegates are both valves that bypass exhaust air around the turbine of a turbocharger in order to regulate turbo speed/boost pressure). The differences are the size of the valve and the placement of the valve.

Pros and Cons For Internal And External Wastegates

External Wastegate Pros

• Multiple valve sizes

• Larger valves respond quicker and smoother to provide even boost control

• Less backpressure in the manifold

• Add multiple valves to get the flow you need

• Fabricate for best air priority

• More efficient design

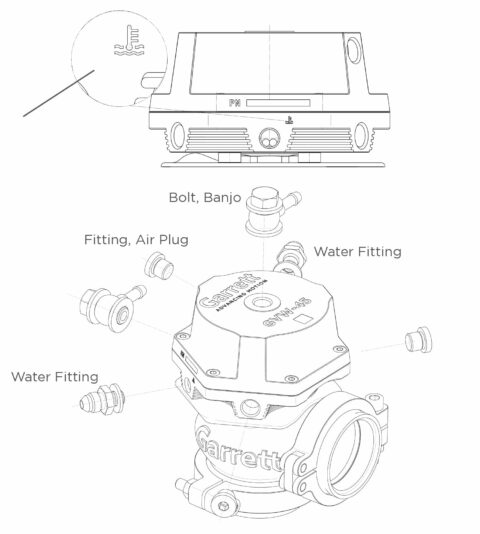

• Better heat control through design and water cooling

• Serviceability through replaceable components

• Color options

External Wastegate Cons

• Larger in size and requires additional fabrication

• Additional component/s to integrate into the turbo system

Internal Wastegate Pros

• Compact and simple because it’s integrated into the turbine housing

• Reliable for lower boost pressures

• Cost effective

Internal Wastegate Cons

• Small valve with limited flow capability

• Cannot increase size of valve

• Slower to respond to changing boost pressures

• Can have issues with overboost in high flowing configurations which can damage the engine

• Bypassed flow can cause turbulence in the housing resulting in additional backpressure and turbo lag

• Valve is integrated into the turbine housing increasing heat buildup

Here you can see the pros and cons of internal and external wastegates. Based on your setup, it may be best to utilize external wastegates especially with higher horsepower applications. Now, in large frame turbo applications you must use external wastegates. For example Garrett only offers internal wastegate turbochargers up to G-Series 35 and GTX35 frame turbochargers. Everything above that ie G-Series 40 and GTX40 only have externally wastegated turbine housings.

These are some of the basic points touched on in the video by Moto IQ but for all the information please click the play button and watch the complete video. For more articles by MotoIQ please visit their site by clicking here