Powering the Future: Driving EV Advancements with Garrett’s In-House Electronics Capabilities

When Garrett introduced the industry-first passenger vehicle E-Turbo, the breakthrough didn’t merely signify an evolution in e-motor technology; it also served as a powerful proof point of the company’s strategic decision to cultivate its electrification capabilities entirely in-house.

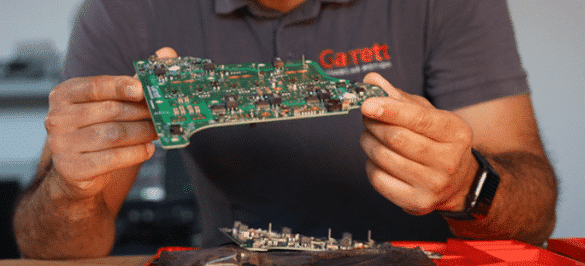

Garrett’s innovative E-Turbo houses a 6kW electric motor directly on the turbo shaft, capable of rotating the rotor at an astonishing +180,000 rpm—entirely independent of the exhaust energy traditionally responsible for driving the turbine. This level of control is made possible by proprietary power electronics, developed internally, that switch on and off at a rapid-fire pace of 30,000 times per second.

“As we pave the path toward an era of ultra-low and zero-emissions vehicles, we’re focusing on developing inverters, compressors, e-cooling systems, and e-motors—all within our in-house expertise,” says Andrew Love, Garrett’s senior electrification manager. “Our commitment to internal capability-building aims to protect intellectual property while eliminating transactional barriers typically associated with outsourcing.”

A Global Team Fuels Garrett’s E-Turbo and Zero-Emission Innovations

The company’s award-winning E-Turbo is just one example of Garrett’s strategy to assemble a dedicated, in-house team of global experts specializing in power electronics, e-motors, and control engineering.

As of today, this interdisciplinary team boasts over 80 specialists across France, the United States, the Czech Republic, and China. Collaborating in state-of-the-art testing laboratories, they engage with automakers to develop electrified solutions for systems at various voltage levels, including 48V, 400V, and 800V.

“With a growing portfolio of differentiated zero-emission products like the E-Turbo and E-Compressor, hydrogen Fuel Cell Compressor, and the recently announced 3-in-1 E-Powertrain and E-Cooling system, we’re helping to make electrified vehicles significantly more practical and efficient,” says Love.

Elevating Efficiency in Power Electronics

Garrett’s power electronics team orchestrates the systems that channel electricity from the battery to the e-motor and other components, with control software acting as the command center.

“Within a span of just four years, we’ve transitioned from bulky inverters to sleek, compact solutions capable of powering e-motors to nearly 200,000 rpm at up to 600 amps, modulating 30,000 times per second,” explains Andrew. “Our aerospace heritage gave us a leg up in power electronics, but it’s our deep automotive know-how that has truly enabled us to bring pioneering innovations like the E-Turbo to market.”

The company’s rapid pace of development is set to accelerate even further. Advances in semiconductor packaging and material science are poised to elevate electronic efficiency levels to an impressive 98%. This compacting trend aligns perfectly with Garrett’s turbocharger development heritage, which has continually achieved higher power density within increasingly smaller packages.

“In the realm of power electronics, our focus remains on optimizing efficiency while reducing packaging size, thereby expanding design options for automakers,” Andrew clarifies.

Pioneering Next-Gen Electrification

Garrett’s strategic shift toward in-house electrification is transformational, offering not just enhancements to its existing turbo line-up but also positioning its technology squarely at the forefront of next-generation hybrid, fuel cell, and battery electric vehicles.

“Our ability to couple proprietary knowledge with robust industrial processes and mass manufacturing adds incredible agility to our operations. It’s this unique blend that allows us to expedite development cycles, ensuring we remain at the cutting edge of automotive electrification,” adds Love.

With a blend of global expertise and nimble operations, Garrett is not just adapting to the electrification evolution—it’s leading it. To discover more about the company’s electric products, click here.