A safe and healthy work environment

Our Health, Safety and Environment (HSE) Management System is designed to provide a systematic framework for minimizing occupational health and safety risks and reducing our environmental footprint. Safety is one of the fundamentals to how Garrett operates. Alongside, we are investing in people’s mental health and have well-being initiatives and assistance programs.

Safety projects

In 2021, we launched 52 Safety projects across 15 sites aimed to further decrease risk levels. The completion of these safety projects was tracked monthly and we reached 100% completion by the end of 2021.

INCREASING FORKLIFT SAFETY

Virtual Gemba walks were conducted in each site with the HSE Regional Leader for an improvement initiative focused on forklift trucks. A total of 53 improvement actions to reduce risks of incidents with forklift trucks were defined in 18 sites and fully completed by the end of 2021.

REDUCING ERGONOMIC RISKS

Each site conducted a refreshment of the Ergonomics Risk Assessment, which resulted in 89 actions being identified in 22 sites, and 74 improvement actions was completed by the end of 2021. Garrett occupational health advisors also reviewed the ergonomics procedure and assessment tools provided by Garrett sites.

Reducing our environmental footprint

Garrett’s commitments to environmental protection focus on our most material issues: carbon, energy, waste and water. Our HSE policy underlines these commitments to create awareness, use natural resources more efficiently, reduce emissions, monitor and report performance, and engage with stakeholders.

Managing product life-cycle

We adopt a cradle-to-gate model for product life cycles — this incorporates supplier parts, transportation to Garrett, and our own production. Life Cycle Assessment reports are aligned to ISO 14040 (principles and framework for life cycle assessment) and available to customers on request. Our products are designed in accordance with the European End of Life Vehicle Directive, meaning that 95% of our hardware is recyclable and 99% is recoverable. In addition, our teams continue to investigate opportunities to increase recycled content in our product parts without compromising performance and quality.

READ MORE IN OUR SUSTAINABILITY REPORT

Latest sustainability news

Garrett Earns EcoVadis Silver Medal for Corporate Social Responsibility, Among Industry’s Top 15%

For the second consecutive year Garrett has improved its Corporate Social Responsibility (CSR) score from EcoVadis, an independent CSR ratings company whose reports are closely…

Garrett Earns “B” Grade from CDP Climate Change, Exceeds Global Company Average

Garrett Motion earned a “B” ranking from the environmental non-profit organization CDP in its annual Climate Change analysis, underscoring Garrett’s commitment to continuously improve its…

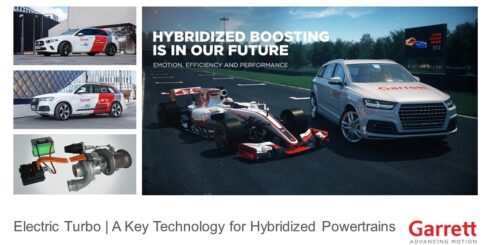

Garrett To Launch Industry’s First Electric Turbo

Tech Breakthrough Points to Accelerating Global Trend for Vehicle Hybridization The announcement comes as automakers turn to electrified engine technology that meets industry challenges for increased energy…

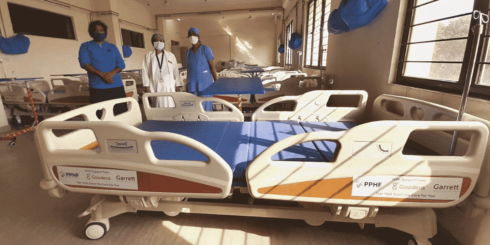

Stronger, Together in India: Garrett Motion Provides Hospital Beds, Meals, PPE During Ongoing COVID-19 Battle

Garrett teams in Pune, Bangalore and Madurai have refocused their community outreach programs to support local populations impacted by COVID-19, providing funding for much-needed healthcare…

Garrett’s Fast Turbo Production Resumption in Wuhan, China Impresses Province Vice Governor During Visit

China’s Hubei Province Vice Governor Haishan Zhao and his team visited Garrett’s Wuhan turbocharger plant on April 8 to learn more about its successful…

WATCH TODAY: Garrett Webinar Dives into Real-World Benefits of Its Groundbreaking, Industry-First E-Turbo

As the automotive world continues to put more focus on hybridized powertrains, Garrett Motion is introducing a new key technology to push the needle further…