Intercooler Tech: What Is Fin Density

Intercooler Tech: Fin Density

In the first intercooler article we talked about heat transfer and selecting the best intercooler for your application. (Click here to go to that article) In this article we will dissect the components of the intercooler core teaching you about fin density, and pressure drop and the engineering behind the industries best performance intercoolers.

Bar And Plate Construction

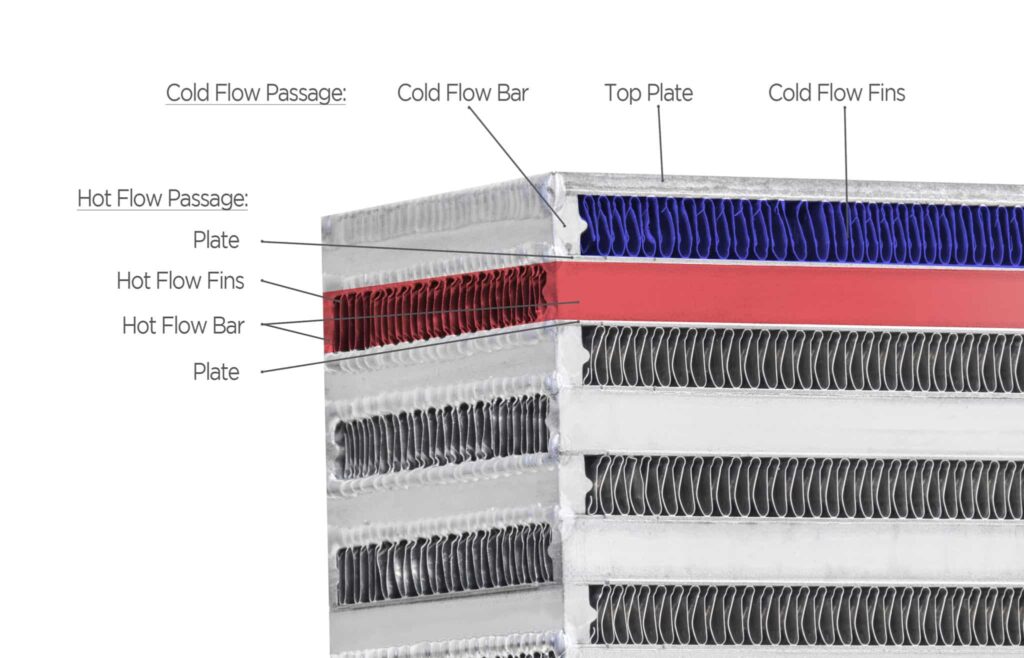

Bar and plate intercoolers are organized by stacking a series of aluminum bars, plates, and fins in a alternating pattern until you reach the desired core height and length. Bars and plates create a framework of sealed passages for the air to travel through while the fins set the row height and facilitates the exchange of heat energy from the hot passages to the cold passages in a process called heat transfer. There are hot flow/ charge air passages and cold flow/ ambient air passages. Air leaving the turbo travels through the hot flow passages of the core and heat is transferred from the air to the fins making the air cooler and more dense before it goes into the engine. The cold flow/ ambient air passages use cold air from the front of the vehicle to continuously cool the hot flow passages. Intercoolers will not function without sufficient cold air flow.

Fin Density

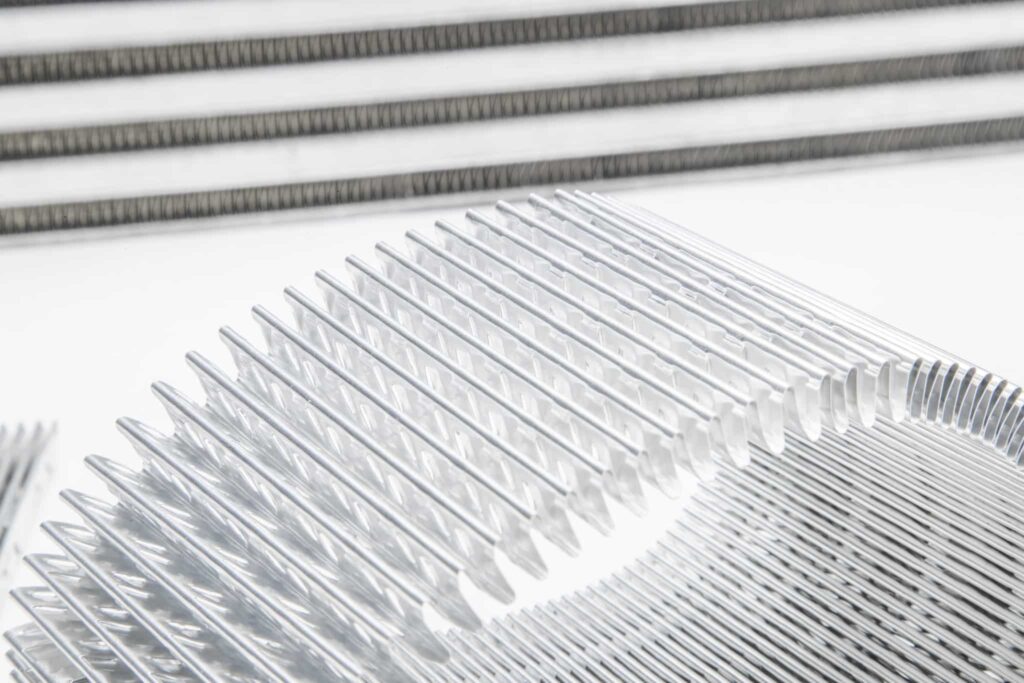

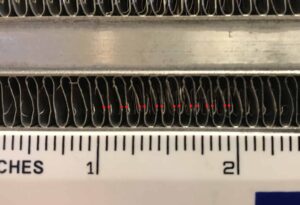

Fin density is measured in FPI or fins per inch. Each fin surface counts as one fin meaning there are two fins per wave. Fin stacks start off as flat sheets of aluminum that are fed through a special machine where they are bent to the desired FPI per row height and length. Garrett manufacturers around 20 different air to air and air to water intercooler cores supporting a range of horsepower from 310 up to 1260. Each of those cores are different in length, width, and height to meet the needs of different performance enthusiasts.

This section has 16 fins per inch. Some sections may have more or less but the average of this core is 16FPI for the cold flow section.

Garrett Intercooler cores utilize a combination of fin density depending on the flow path of the core. For example, the cold flow path or the front of the intercooler commonly has a higher density fin count to allow for better thermal performance and cooling. Core width/ cold flow can range from 3 – 5 inches so higher fin density is critical with the short span the ambient air travels across to cool the charge air passages. Additionally, the cold air passages are not sealed or pressurized like the charge air passages, so your ambient air flows through, cools the hot passages and evacuates into the engine compartment.

Hot flow passages have a longer run spanning from 11-28 inches in some intercooler cores. The hot flow path is a series of sealed chambers with fins spanning the entire length. There is a lot of surface area for heat transfer to take place and for that reason, the hot chambers have a lower fin density. This also helps reduce pressure drop as the charge air travels from one side to the other.

Pressure Drop

By now you may be asking what is pressure drop and how does fin density affect it? Pressure drop is the difference in pressure between two points caused by flow resistance. An example of pressure drop is when the air pressure leaving the intercooler is less than the pressure that went in. You may never actually see this happening because your turbo will work harder (spin faster) to deliver the correct PSI to the engine. The faster a turbo spins the hotter the air is so it’s critical to use an intercooler that has a good balance of fin density so you don’t overwork the turbo.

Think about driving down the road with your hand out of the window and your palm facing forward. Your hand is interrupting the flow of the air and it must find a way around your hand to pass. Now imagine you and 10 friends in a limousine with your hands out of the window one after another. The last person in line will not feel the same flow as the first person because of pressure drop.

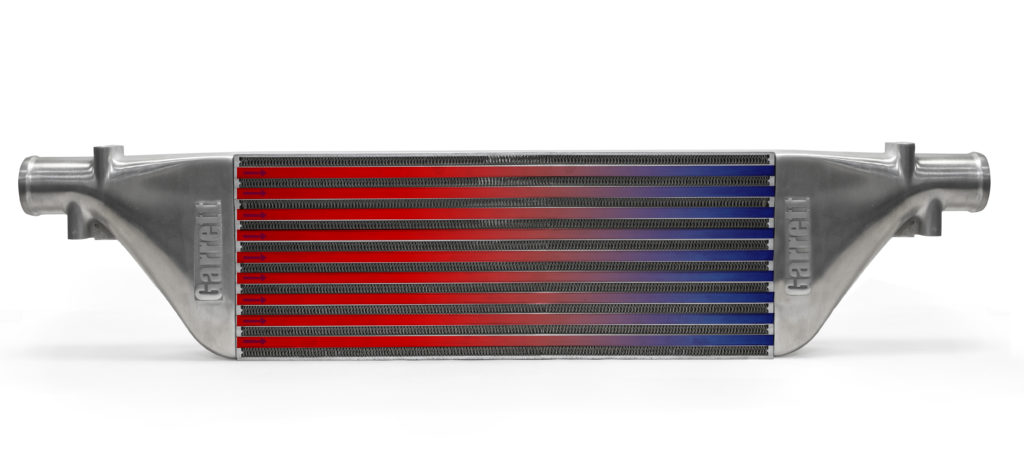

Here we have an intercooler core mocked up with end tanks. End tanks direct the air flow from the turbo, to the core, and back to the engine.

Conclusion

Now you understand the concept of fin density and pressure drop and the importance of choosing an intercooler core that has a balanced combination of fins selected for both hot and cold flow passages. Garrett intercooler cores come in a variety of sizes for many different horsepower ranges and they are all flow tested and optimized for performance. For more information on Garrett intercooler cores visit the product page here.

In our next article we will discuss fin offsets and the boundary layer concept. This is one more way the Garrett Intercooler product line stands out from the competition. Thank you for reading.