Accessing the Knowledge Center effectively requires a simple, one-time registration.

Clean oil is your turbo’s best friend.

It takes just a few seconds for a lack of oil to cause catastrophic damage to a turbocharger. We also know that contaminated oil is the biggest single cause of turbo failure.

So, in this series of articles we dive deep into the importance of lubrication. We aim to help garage technicians build their knowledge about oil viscosity, pressure and supply – and to spot tell-tale signs of damage caused by contamination. We also cover the essentials for installing a replacement turbo, including a step-by-step guide to priming the turbo before starting the engine. Getting this wrong is the fast route to a turbo kill!

Why turbos need a clean oil supply

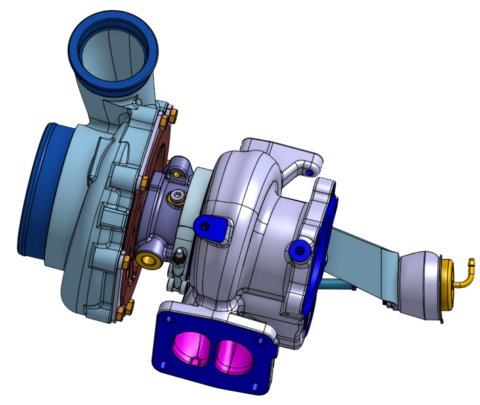

Turbochargers are highly complex machines, subject to remarkably high rotational speeds and operating to incredibly precise clearances. It’s essential that oil lubricating the bearing system is clean, of the correct grade and flowing at the correct pressure because contaminated oil is one of the biggest risks to turbo performance and reliability.

Dirty oil is usually the result of poor filtration of the metallic particles resulting from engine wear. This gradual buildup of ‘dirt’ will lead to a wearing of the turbo shaft, journal bearings and thrust bearings.

Our article on viscosity and oil outlines the critical contribution that clean oil makes to turbo performance and longevity.

Critical lubrication in turbo installations

Boosting your understanding of the relationship between oil and Garrett turbo architectures could save a lot of time and potentially money, particularly when it comes to installing a turbo. In our article on oil supply in turbo replacements, we look at related topics such as turbo sealing systems, vehicle running conditions, oil pressure and feedlines.

There are also tips on how to ensure oil is properly drained from a turbo as well as some pitfalls to avoid associated with oil supply. Critically, we offer guidance in priming a replacement turbo installation to ensure oil is available to the bearing system before full engine start-up. If not done correctly, the turbo will likely fail within just a few seconds…and won’t be covered under warranty.

These articles form part of Garrett Motion’s Knowledge Center which aims to provide mechanics with essential information on turbo maintenance, installation and performance. You can also check Garrett’s Installer Connect and work through our online training modules to achieve turbo expert status.